Product model:

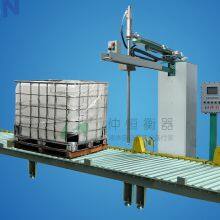

■ GAF1500LA-EX, a 200LX4 barrel-to-barrel filling production line

■ Product application: It is suitable for filling liquid materials which are prone to foam and explosion, such as cleaning agent, detergent, tetrahydrofuran, cyclopentane, n-pentane, methyl acetate, explosive solvent, etc.

Basic parameters:

■ Power supply: AC220V 50/60HZ 0.1KW

■ Air source used: 0.5~0.7 Mpa

■ Filling capacity: 100~1200kg; grading value: 0.1kg

■ Filling capacity: 200L 45~60 barrels per hour, IBC 10~12 barrels per hour.

■ Filling accuracy: ≤ 0.1% F.S 。

■ Gun filling material: SUS304/SUS316

■ explosion-proof grade: Exdemb11BT4

Product features:

■ Swing-arm gun, with large turntable bearing and linear track, can move left and right, back and forth around the column, which is completely suitable for filling 200L four barrels and IBC barrels;

■ Equipped with left and right disc brakes and front and rear side brakes, it prevents the filling gun from touching the barrel mouth, making filling easier and more accurate;

■ Double-layer anti-side impact platform, closely protecting the load unit, making the quality more rock-solid; The quick operation panel of the gun handle makes the operation more flexible.

System features:

■ Chinese display: 7-inch all-Chinese color LCD screen, with Chinese fool-like guide operation;

■ Intelligent and efficient: the weighing platform is forbidden to fill without barrels, differential pressure type zero-time bucket collision protection, automatic peeling, intelligent anti-stupidity, fault detection, etc., which can realize simultaneous filling and capping by one person;

■ Equipment filling gun: originated from German technology, with five-layer seal design to ensure no dripping after filling;

■ Quick positioning: Swing filling, which can move left and right, back and forth, suitable for IBC ton barrel and 50GL four-way filling;

■ Easy operation: Quick operation key for gun filling starts/stops, filling height can be adjusted by 250mm, suitable for barrels of different specifications;

■ Function switching: net weight/gross weight, automatic/manual function switching mode;

■ Accurate and fast: Equipped with large and small ball valve groups and filling guns, large, small and micro three-stage filling design, to prevent the change of incoming flow rate from affecting the filling accuracy, so that the filling accuracy is high and the filling speed is fast;

■ Imported configuration: original Siemens PLC/ Mitsubishi PLC (optional), OMRON relay of Japan, Schneider switch of France, Festo cylinder and ball valve group of Germany (optional), Siemens man-machine interface, to ensure the overall performance of the equipment is stable, fast and accurate, firm and durable;

Operation process:

■ Turn on the machine-the forklift truck puts the bucket into the weighing platform-operate the handle of the filling gun, press the brake release button, and quickly match the left and right, front and back-release the brake release button, and the filling gun is firmly fixed-press the [Start] key-the filling gun is automatically inserted into the bucket mouth-automatic peeling-automatic opening of the filling gun and ball valve group-three sections of filling, big, small and micro-filling.

■ Function selection: double-gun double metering/multi-gun multi-metering/nitrogen charging device/other customization.

Send Inquiry to This Supplier

You May Also Like

-

Liquid Filling MachineNegotiableMOQ: 10 Bags

-

GD6 Bag-feeding Packaging MachineNegotiableMOQ: 10 Bags

-

Bag-feeding Packaging Machine (double Feeding)NegotiableMOQ: 10 Bags

-

Bag-feeding Packaging Machine (positive Pressure Bag Opening)NegotiableMOQ: 10 Bags

-

Bag-feeding Packaging Machine (zipper Self-supporting Bag)NegotiableMOQ: 10 Bags

-

Special Packaging Unit for Small ParticlesNegotiableMOQ: 10 Bags

-

Multi-material Special Packaging UnitNegotiableMOQ: 10 Bags

-

Multi-material Special Packaging UnitNegotiableMOQ: 10 Bags

-

Special Packaging Unit for Microwave PopcornNegotiableMOQ: 10 Bags

-

Particulate Special Packaging UnitNegotiableMOQ: 10 Bags