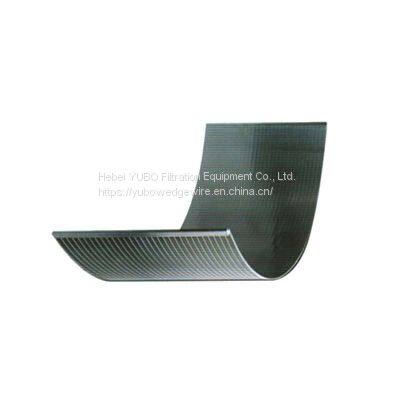

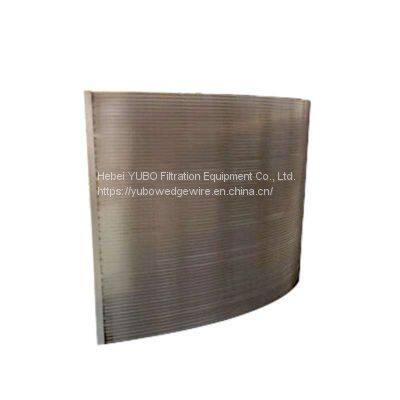

Stainless steel wedge wire screen parabolic curved screen plate for sewage treatment is a screen surface for the arc to open away from wet fine screening equipment. The different feeding, methods are divided into gravity and pressure arc curved sieve screens. Artesian curved screen is a small curvature, low pressure, low-speed feeding curved screen, thanks to a certain height difference of the feed material screening and to the mouth, along the arc tangent in the direction screen surface for gravity feed. Pressure is a sweeping curved screen, high-pressure, high-speed feeding curved screen, which is the use of a sand pump nozzle into the raw material to the slurry under the action of the material at high speed along the curved screen surface tangent to the direction of the pressure feedstock.

Features

1. Energy-Efficient - operates with no moving parts and with no energy input.

2. Space Efficient - treats up to 122 liters per second per square meter of floor space.

3. Quiet Operation - No moving parts mean no mechanical or electrical vibrations.

4. Accurate Sizing - can be used for sizing solid particles down to 0.2 mm (0.008").

5. Low Maintenance - the profile wire screen resists clogging by near-size particles, and the all-stainless steel construction ensures a long, corrosion-free installation.

6. Easy Screen Replacement - a typical screen can be replaced in 10 minutes with no tools.

7. Flexible Design - we can supply units with any features you may require.

Work Principle

The Stainless steel wedge wire screen parabolic curved screen plate for sewage treatment mainly works as fitting panels for rotary screens or vibrating screens. Each unit is designed to suit the specific requirements of the customer. Consisting of a basic outer casing, which can be manufactured in mild steel or stainless steel, each unit incorporates a distribution chamber and feed weir; over which the effluent passes onto the wedge wire panel which is set at right angles to the flow to enable the separating process to commence. The separated solids collect on the lower half of the screen to drain and compact, they then slide by gravity onto a solids discharge chute.

Send Inquiry to This Supplier

You May Also Like

-

False Bottoms Screens for Grain BrewingUS$ 105 - 125MOQ: 1 Set

-

Water Treatment Sand Filter NozzlesUS$ 5.5 - 6.5MOQ: 10 Sets

-

Wedge Wire Screen CylindersUS$ 50 - 150MOQ: 1 Set

-

Radical Reactors Wedge Wire ScreenUS$ 1 - 100MOQ: 1 Set

-

SS Wedge Wire Cylindrical Strainer FilterUS$ 1 - 125MOQ: 1 Set

-

Wedge Wire Screen Panel for Chemical PlantUS$ 1 - 125MOQ: 1 Set

-

Stainless Steel Cone Filter Punching ScreenUS$ 25 - 55MOQ: 1 Set

-

Slurry Thickener Custom DesignUS$ 1 - 999MOQ: 1 Set

-

Stainless Steel Sintered Wire Mesh Perforated Metal TubesNegotiableMOQ: 10 Sets

-

Wedge Wire Coal Vibratory SieveUS$ 1 - 200MOQ: 1 Set