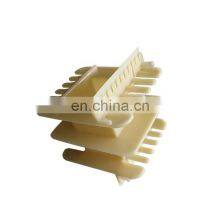

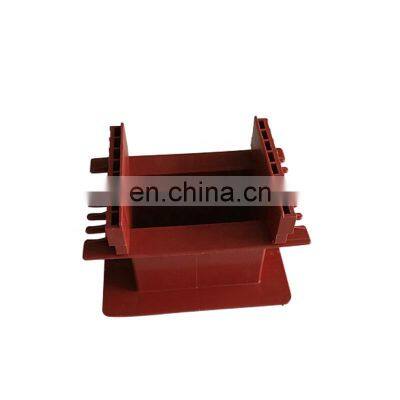

Precision Plastic Injection Mould High-quality Transformer Bobbin Manufacturer Core Smd Plastic Injection Molding

SPECIFICATIONS FOR PUSHI INJECTION MOULDS | ||||||

Injection mold standard | HASCO, DME, MISUMI, China lKM Standard | |||||

Please provide | 2D, 3D, samples, or the size of the multi-angle pictures | |||||

Mould material | 45#, 50#, P20, 738, 738H, 718, 718H, NAK80, 2316, 2316A, S136, S136H etc | |||||

Product material | ABS, PA6, PA66, PP, PC, TPU, POM, PBT, PVC, TPE, TPV, TPO, TPR, PE, HDPE etc | |||||

Cavity | Single-cavity, Multi-cavity or by requested | |||||

Runner system | Cold runner or Hot runner | |||||

Mould precision | ±0.01mm | |||||

Mould Life | 50-100 million shots | |||||

Software | CAD, PRO-E, UG, Rhinoceros etc | |||||

Design Time | 1-3 days (normal circumstances) | |||||

Main thechnology | Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes etc | |||||

Customized injection mold steps

1. Customers will provide 3D drawings or sample inquiry, and we will quote according to 3D drawings or samples.

2. Negotiations include mold price, mold quality, mold material, mold cavity material, mold size, surface effects, technical requirements, mold life, warranty period, product weight, product cost, delivery time, logistics mode, payment mode, etc.

3. Confirm the order. Proforma invoice or commercial invoice.

4. T/T deposit. 50% T/T in advance ,balance before shipment.

5. DFM (Design For Manufacturing), Ensure quality. Mould design, mould drawing confirmation.

6. Mold processing. Feedback the processing progress every week, we will show you the pictures of mold processing.

7. Sample confirmation. Express sample, confirm sample, mass production.

8. Product packaging. Wooden case, carton or custom made.

9. Delivery. By Sea, By air, etc. Pay the balance.

Send Inquiry to This Supplier

You May Also Like

-

Agriculture Using Plastic Shape Moulds Heart, Star, Square, Flower Shape Cucumber and Fruit MouldNegotiableMOQ: 500 Pieces

-

GYC Small 300-600kg/h Toilet Soap Making Machine From OilNegotiableMOQ: 1

-

OEM Customized Molded Enclosure Injection Plastic Molding For ElectronicsNegotiableMOQ: 1

-

Vanity TopNegotiableMOQ: 1

-

Brand New Waterproof Pvc Flooring With Great PriceUS$ 80 - 117MOQ: 1 Piece

-

Mould For ScrubberNegotiableMOQ: 1

-

Fully Automatic Cotton Swab Making Machine With Packing And Drying | Cotton Bud Maker Machine Wooden Cotton Swab Making MachineUS$ 23,500 - 23,500MOQ: 1 Set

-

Plastic Motor Part Mould, Laptop Plastic Parts Mould Such as Side Body Motorcycle, Fairying Covers for Motorcycle!US$ 0.1 - 2MOQ: 5000 Pieces

-

6.35mm Adjustable M2-M10 Carbon Steel Body Die Holder Wrench Set for Power ToolsUS$ 1 - 30MOQ: 640 Pieces

-

2016 Hot Selling Concrete Plastic Paving Mould for Interlock Tile MakingUS$ 1 - 5MOQ: 500 Pieces