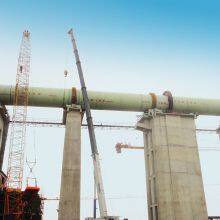

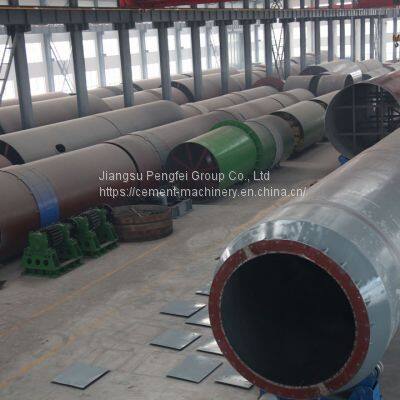

Cement Rotary Kiln

Description of Cement Rotary Kiln:

As the main equipment in both of the cement clinker dry and wet process production lines, this cement rotary kiln is widely used in metallurgy field, chemical industry, building refractory material sector, environmental protection field, and so on. It mainly consists of cylinder body, supporting device, supporting device with catch wheel, driving device, movable kiln head, sealing equipment of the kiln end, coal spraying pipe, etc.

As for its parts, advanced hydraulic catch wheel equipment has been equipped. Metering plunger pump with high accuracy, high-precision speed control valve and contact-type graphite block sealing device have been fitted. To improve its automaticity, industrial TV has been used to watch the fire, and its process flow is able to imitate fluorescent screen. The calcination zone can be displayed clearly on the infrared scanistor. All of these devices make it more convenient, reliable and visualized to operate. Compared with other similar products, our cement rotary kiln has a 10% higher operation rate, 5%-10% higher productivity, and 15% lower heat consumption.

Besides cement clinker, it can also be used to calcine clay, as well as to dry limestone and slag. In the production line of refractory materials, it can be employed to calcine raw materials so as to make their size stable and their intensity stronger before processed into special shapes. And it can also be used in production lines of non-ferrous and ferrous metals, such as iron, aluminum, copper, zinc, tin, nickel, tungsten, chrome, etc. It can be employed in the roasting and sintering of ores, ore concentrates, intermediates, etc.

In the process of ore dressing, this cement rotary kiln can be used to magnetize and roast poor iron ores to enhance their magnetism, which is good for their magnetic separation. In the field of chemistry industry, it can be used for producing soda, as well as for calcining phosphate fertilizers and barium sulphide, and it consumes less electricity and is capable of making use of middle and low grade phosphate rocks. Additionally, in the sector of environmental protection, it can be used to burn hazadous wastes or rubbish without other waste discharge. For it, wastes can be used as fuels.

| Specification (m) | Φ2.8/2.5 x44 | Φ3x48 | Φ3.2x50 | Φ3.3x50 | Φ3.5x54 | Φ4x60 | Φ4.3 x64 | Φ4.8x74 | Φ5.0 x74 | Φ5.6x87 | Φ6.0x95 | ||

| Production Capacity (ton/day) | 300 | 600-700 | 1000 | 1200 | 1500-1800 | 2500 | 3500 | 5000 | 6000 | 8000 | 10000 | ||

| Inclination of kiln shell (%) | 3.5 | 3.5 | 3.5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | ||

| No. of supports | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | ||

| Type of thrust roller | Mecha - nical | Mechanical or Hydraulic | Hydra - ulic | Hydra - ulic | Hydra - ulic | Hydra - ulic | Hydra - ulic | Hydra - ulic | Hydra - ulic | Hydra - ulic | Hydra - ulic | ||

| Rotating Speed of Kiln Body | Main driving (r/min) | 0.445 -2.22 | 0.676 -3.38 | 0.36-3.57 | 0.36-3.57 | 0.39 -3.9 | 0.41- 4.07 | 0.4 -4.0 | 0.35 -4 | 0.35 -4 | Max 4.23 | Max 5 | |

| Auxiliary driving (r/h) | 4.75 | 9.36 | 6.5 | 5.61 | 7.66 | 8.2 | 7.93 | 8.52 | 7.58 | 8.7 | 9.2 | ||

| Main driving part | Motor | Model | ZSN4 -225-21 | Z2-101 | ZSN4-280-091B | ZSN4-280-091B | ZSN4-315 -092 | ZSN4 -355 -092 | ZSN4 -355 -12 | ZSN4-400-092 | ZSN4-450-092 | ZSN4-450-12 | ZNS4-500 -092 |

| Rated power (kw) | 55 | 100 | 160 | 160 | 220 | 315 | 400 | 630 | 710 | 800 | 950 * 2 | ||

| Speed regulation range (r/min) | ~1000 | ~1500 | 1500 | 1500 | 1000 | 1000 | 100 ~1000 | 1500 | 87.5 ~1000 | 100 ~1000 | 100 ~1000 | ||

| Rated voltage (V) | 440 | 220 | 440 | 440 | 440 | 440 | 440 | 660 | 660 | 660 | 660 | ||

| Reducer | Model | ZS145-1-1 | ZS145 -1-1 | ZSY-450-40-V | ZSY450-40 | NZS995-28VIBL | YNS 1110 -22.4 VBR | YNS 1400-31.5VIBL | JH710 C-W30 5-40 | JH800 C-28 | JH900 C-SW 305-25 | JS900 C-SW305 -28 | |

| Total speed ratio | 49-63 | 50 | 40 | 40 | 28 | 22.4 | 31.5 | 42.226 | 26.812 | 23.901 | 26.646 | ||

| Auxiliary driving part | Motor | Model | Y122M-4 | Y160M-6 | Y160M-4B | Y160M-4 | Y200L1-6 | Y180L -4 | Y200L-4 | Y250M -4 | Y250 M-4 | Y280M -4 | Y315M 1-4 |

| Rated power(kw) | 4 | 7.5 | 15 | 11 | 18.5 | 22 | 30 | 55 | 55 | 90 | 132 | ||

| Speed regulation range (r/min) | 1440 | 970 | 1460 | 1460 | 970 | 1470 | 1470 | 1480 | 1480 | 1480 | 1490 | ||

| Rated voltage (V) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | ||

| Reducer | Model | ZL35-16 | ZL35-7-I | ZSY160-31.5-II | ZSY355-31.5 | ZSY355 | YNS 440 -45 II R | YNS497-45ZC | JH220 C-W30 2-28 | JS280 C-45 | ZSY400 -35.5-I | ZSY450 -35.5-I | |

| Total speed ratio | 40.44 | 14 | 31.5 | 31.5 | 45 | 45 | 45 | 28 | 45 | 35.795 | 35.795 | ||

| Total weight (excluding refractory brick) (ton) | 177 | 207 | 256.5 | 281 | 341 | 434 | 550.5 | 854 | 894 | 1201 | 1580 | ||

| Weight of kiln head cover(ton) | 20 | 22 | 25 | 27 | 28 | 35 | 36 | 58 | 58 | ||||

Note: parameters in the form are only for reference, and specific ones should refer to the contract.

Send Inquiry to This Supplier

You May Also Like

-

Cement Rotary Kiln BurnerUS$ 37,000 - 2,130,000MOQ: 1 Set

-

Cement Rotary KilnUS$ 100,000 - 200,000MOQ: 1 Set

-

Support Roller for Cement Rotary KilnUS$ 1,500 - 6,000MOQ: 1 Metric Ton

-

2013New Hot Cement Rotary KilnUS$ 3,000 - 160,000MOQ: 1 Set

-

180-12000tpd Cement Rotary Kiln PlantUS$ 15,000 - 80,000MOQ: 1 Set

-

4-09 Cement Rotary Kiln BlowerUS$ 600 - 8,000MOQ: 1 Set

-

Best Selling Profession Custom Nickel Carbonate Cement Rotary KilnUS$ 70,000 - 700,000MOQ: 1 Set

-

Hot Selling Rotary Kiln for CementUS$ 2,000 - 20,000MOQ: 1 Set

-

Samll Small Metallurgy Rotary Kiln for CementUS$ 1,000 - 1,000,000MOQ: 1 Set

-

Rotary Kiln LncineratorUS$ 1,000 - 200,000MOQ: 1 Set