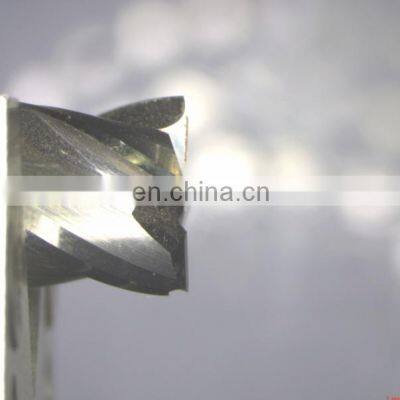

Milling Cutter Measuring System For Edge Width Angle Measurement

Product Application

Parameters | ||

X axis travel | 80mm | |

Y axis Travel | 60mm | |

Z axis measuring range | 60mm | |

Max tool Diameter | 20mm | |

Max tool length | 200mm | |

Working distance | 90mm | |

Lens | 0.7-4.5X dented zoom lens | |

Camera | 2M pixel HD camera/5M pixel HD camera(Optionsl) | |

Linear scale resolution | 0.0001mm | |

Magnification | 12.6X~79.2X/25.2X~158.4X(Optional) | |

Field of view | 27*20mm~4.3*3.3mm/13.5*10mm~2.3*1.6mm(Optional) | |

Measuring accuracy | X~Y,(2.5+L/100)µm,L is the measured length | |

PC | ALL-IN-ONE PC system, Windows 10 OS, with 24" LCD monitor | |

Illumination | 8 sections LED ring light, contour light and flexible auxiliary light, all software control and programmable. | |

Input format | DXF files | |

Output format | EXCEL,DXF | |

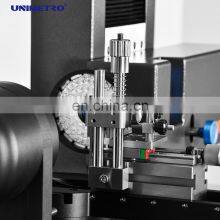

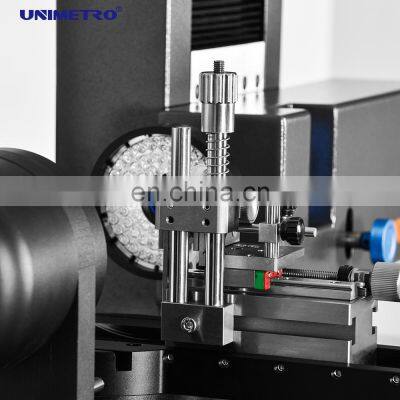

Advanced Design

--HD image capturing and display combination, also microscope magnification level is optional.

--Stable and accurate V block for easy tools holding and alignment.

--Mechanical fixed measuring angle of 0 degree and 90 degrees are available on the rotary stage.

--High accuracy encoder is embedded in the rotary table, offers precise angle location for users.

--Multiple section programmable LED ring light for surface illumination, also including contour lighting and free angle auxiliary light for standard features.

--SMARTOOL measuring software offers specific measuring function for cutting tools.

--Automatic edge detection, fast angle measurement with reticle, CAD element comparison functions are available.

--Measuring result fast output to EXCEL file report or CAD file.

--ALL-IN-ONE PC system makes the machine more stable.

mechanical fixed angles, 0 degree and 90 degrees. At the 0 degree position users are able to measure Tool End, Tool End - Center shaft, Tool End - front angle, etc. And 90 degrees position is available for Helix angle, Axial Front angle, First Rear angle, Second Rear angle and Tilting Edge angle, etc.

If other angle location should be required, users can also use the accurate encoder which is embedded in the rotary table to obtain. The angle reading is display in the software.

Free angle auxiliary light

Contour light module

Base table

Tools holder

easy and intuitive to operate and offers numerous measuring and evaluation algorithms specifically for tools manufactured or sharpened in grinding business.

Easy operation

Dynamic Real Time curve view

Fast angle measuring with retical

CAD comparison

minimize the after sales service. This will help our partners to manage the products details and sales with minimize labor cost

and staff training cost.

2.Auto CAD/CAM; Pore

3.Industry 3D print machines.

4.Fast Prototype from your Ideas.

5.Talented Engineering team Support within 24 hours feedback.

Send Inquiry to This Supplier

You May Also Like

-

CNC Fixture Clamps Measuring Surface Plate FixtureNegotiableMOQ: 1

-

Vision Measurement Instruments Flexible FixtureNegotiableMOQ: 1

-

CNC Fixture Clamps For CMMNegotiableMOQ: 1

-

Vision Measurement Instruments Flexible FixtureNegotiableMOQ: 1

-

Vision Measurement Machine Flexible Fixture Of VMMNegotiableMOQ: 1

-

CNC Fixture Clamps Measuring Surface Plate Fixture Of CMMNegotiableMOQ: 1

-

High Quality CNC Fixture Clamps Measuring Surface Plate Fixture Of CMM MachineNegotiableMOQ: 1

-

CNC Fixture Clamps For Fixture CMMNegotiableMOQ: 1

-

CNC Fixture Clamps Measuring Surface Plate Fixture Of CMMNegotiableMOQ: 1

-

CNC Fixture Clamps Measuring Surface Plate Fixture Of CMM MachineNegotiableMOQ: 1