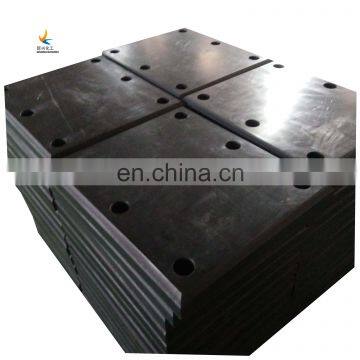

Plastic Uhmwpe Sheet Impact Resistant/Impact Bars for Conveyor Belts/UHMWPE Impact Bars for Conveyor Belts

UHMWPE Impact Bars

Impact bar is used in the loading area of the belt conveyor to replace the traditional cushion rollers. The loading zone of a conveyor is a critical area. The type and size of material as well as height of drop are the main factors causing damage not only to belt but also the rubber rings and bearings of the conventional impact idler rolls.

The impact bar is a combination of three different layers. The top layer is made of UHMWPE for smooth movement of belt, thanks to its low dynamic co-efficient of friction. The middle layer is of rubber to cushion the impact load while the lower layer is made of aluminum, which acts as a fastening device with the main support frame or cradle. The cradlers are custom built to suit specific applications. The installation of impact bar is made is such a way that the belt is not in touch with the bar when running empty. The belt comes in contact with the bar only when it is running under loaded condition.

Features:

- No moving parts, no lubrication ; hence zero maintenance

- Extremely low coefficient of friction

- High Abrasion resistant

- Shock absorbing

- No belt sagging, no belt mistracking

- Protect belt from tear and puncture

- Reduces spillage

- Friendly with the side skirt sealing system as it eliminates the gap which occurs commonly between two conventional impact idlers

Our Company Advantages

- Professional manufacturing experience with own factory

- 100% raw material for processing

- Strict quality Control

- In stock for quick delivery

- OEM available, color, size, shape and specifications can be customer-order

- ISO 9001:2008 Certification

Send Inquiry to This Supplier

You May Also Like

-

Low Coefficient of Friction and High Impact Endurance Conveyor Equipment Guide RailUS$ 3 - 6MOQ: 500 Kilograms

-

UHMWPE Plastic Chain Guide/uhmwpe Guide Rail/uhmwpe Guide BarUS$ 3 - 6MOQ: 500 Kilograms

-

UHMW-PE Chain Guides/polyethylene Conveyor Roller Chain Guides/pe-uhmw Chain GuidesUS$ 3 - 9MOQ: 500 Kilograms

-

UPE Polyethylene Chain Aluminium Profile Guide RailUS$ 3 - 9MOQ: 500 Kilograms

-

PE 1000 and PE 2000 Chain Guide, Wear Strip in UHMWPE MaterialUS$ 3 - 6MOQ: 500 Kilograms

-

Curve UHMW-PE Polyethylene Plastic Chain Guides Rail or Corner TrackUS$ 3 - 9MOQ: 500 Kilograms

-

Uhmwpe Chain GuideUS$ 4 - 5MOQ: 500 Kilograms

-

Conveyor Uhmwpe Chain GuideUS$ 4 - 5MOQ: 500 Kilograms

-

Uhmwe Plastic Chain Guide and Guide RailUS$ 4 - 5MOQ: 500 Kilograms

-

Uhmwpe Guide Track Rail for ConveyorUS$ 4 - 5MOQ: 500 Kilograms

Recommended Categories

Explore top categories and find suppliers for your specific needs-

Amily Tong

Hi there! Welcome to my shop. Let me know if you have any questions.

Amily Tong

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.