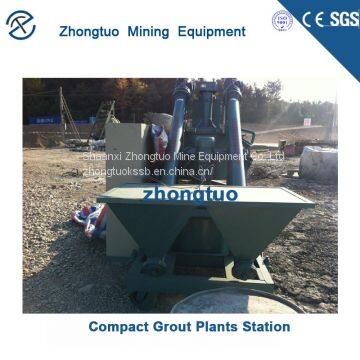

China Compact Grout Plants Station Manufacturers

Automatic grouting equipment and colloidal grout mixer belongs to movable mortar mixing storage equipment, mainly including cement mortar high-speed mixing system and cement mortar storage (low speed agitation anti solidification) system. Each time high speed mixing of 400 liters of mortar, stirring 6-10 cubic meters per hour. The high speed mixing bucket is equipped with weighing measuring device and automatic feeding, which can greatly reduce the labor intensity of construction personnel.

Characteristics of Grouting station:

(1) automatic operation

Use only setting powder and water ratio and time of stirring, the Compact Grout Plants Station will automatically control water and on powder and stirring time, and mixing is completed automatically open the discharge valve, the cement slurry after high speed stirring into the low-speed storage tank for standby. The automatic operation can completely avoid the influence of manual operation on the mixing process, and ensure the mixing quality.

(2) high speed mixing.

High speed stirring can make powder and water fully stir. The speed of the high-speed mixing drum of the car is as high as 1000 rpm, which is 10-20 times as much as that of other mixers.

(3) low speed storage and anti freezing.

The car is equipped with a larger capacity of low speed mixing drum, can be 2-3 times after high-speed mixing of cement slurry, to meet the needs of large capacity use.

(4) walking system with its own.

All the equipment of the trolley is mounted on a single axle frame, which can be easily used by other vehicles to be towed to the place of use, and the whole machine is easy to move

The automatic grouting trolley equipment, grouting equipment grouting equipment structure is novel, with high production efficiency, good mixing quality, beautiful appearance and so on.

Working principle of grout mixer machine:

(1) automatic operation

Use only setting powder and water ratio and time of stirring, the intelligent grouting trolley will automatically control water and on powder and stirring time, and mixing is completed automatically open the discharge valve, the cement slurry after high speed stirring into the low-speed storage tank for standby. The automatic operation can completely avoid the influence of manual operation on the mixing process, and ensure the mixing quality.

(2) high speed mixing.

High speed stirring can make powder and water fully stir. The speed of the high-speed mixing drum of the car is as high as 1000 rpm, which is 10-20 times as much as that of other mixers.

(3) low speed storage and anti freezing.

The car is equipped with a larger capacity of low speed mixing drum, can be 2-3 times after high-speed mixing of cement slurry, to meet the needs of large capacity use.

(4) walking system with its own.

All the equipment of the trolley is mounted on a single axle frame, which can be easily used by other vehicles to be towed to the place of use, and the whole machine is easy to move.

(5) equipped with pumping grouting system.

The car is equipped with continuous grouting equipment (slurry pump), forming a complete set of equipment from the beginning of the basic material to the completion of the final grouting. Grouting can automatically control the start and stop of the grouting equipment according to the grouting pressure, so as to ensure the pressure during the holding period is within the prescribed range.

(6) the mixing data can be traced back.

The data recording system of the controller can record the stirring data of the trolley more than 8000 times, including the date, time, quality of mixing, weight of water and powder, etc., and can be connected with the ordinary computer when needed, and read the relevant data for reference.

Notice: mixer and automatic feeder must be cleaned inside, especially in winter, which can prolong the life.

Send Inquiry to This Supplier

You May Also Like

-

Hydraulic Stressing Jack|Post Tension Working Hydraulic Stress Jack for Bridge Construction Hydraulic Stressing JackUS$ 700 - 3000MOQ: 1 Set

-

Flat Jack Lock Nut Cylinder|A Portable Hydraulic Jacking Jack for Bridge Replacement Rubber ProductionUS$ 100 - 2000MOQ: 1 Set

-

Mono Strand Pulling Jack|Prestressed Construction Front Pulling Mono Stressing JackUS$ 600 - 650MOQ: 1 Set

-

Hydraulic Strand Jack System|Strand Jacking is Pre-fabricated Building Sections Are Carefully Lifted and Precisely PlaceUS$ 5000 - 20000MOQ: 1 Set

-

Strand Pusher Machine|Electric Stranding Machine Conforms to Bridge Construction Standard Strand Pusher MachineUS$ 800 - 2000MOQ: 1 Set

-

Anchor Extruder for Post Tensioning|Used for P Anchor Extrusion Connection of Bridge Anchor EndUS$ 1000 - 1200MOQ: 1 Set

-

Intelligent Prestressed Tension|Numerical Control Prestress Oil Pump Synchronously Controls Two or More Jacks to ImproveUS$ 21000 - 28000MOQ: 1 Set

-

Colloidal Grout Mixer|Multi Function Grouting Trolley for Bridge Numerical Control Precise Feeding Stirring and GroutingUS$ 15000 - 18000MOQ: 1 Set

-

Prestressed Eletric Oil Pump|digital Control Hydraulic Electric Oil Pump Used in Bridge JackUS$ 930 - 1200MOQ: 1 Set

-

Multi-Holes Anchorage|Post - Tensioned Prestressed Anchors for Concrete Bridge Construction Post Tension AnchorUS$ 100 - 1000MOQ: 1 Set