Home > Products > New product > Composite Insulating Foam Cement Panel

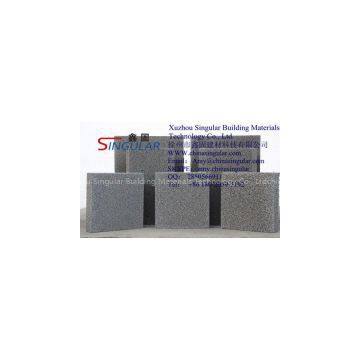

Composite Insulating Foam Cement Panel

- T/T L/C D/P D/A

- 7 days

You May Like

Product Details

| Brand Name | Singular | Place of Origin | China | |

Product Description

Composite Insulating Foam Cement Panel

As a new type of insulated,non-ignitable and durable inorganic wall material with features of highstrength, light weight, heat preservation, insulation and low water absorption,fire prevention and weather-proof, this product is the ideal greenenergy-saving construction product in current times. According to the drydensity and thermal conductivity, it can be classified into type A and type B,while by its distinct foaming principles, it can be named as physical foam andchemical foam.

I. Application:

Heat insulationmaterials in the internal and external wall of construction, and in ground,roof, balcony ceiling and cellar ceilings of construction.

II. Features:

1. Superior fire prevention: as a kind ofnon-ignitable, inorganic heat insulation material at A level, it can remainnon-ignitable and non-toxic under high temperature or fire conditions. It issafe and environmentally friendly without radioactivity.

2. Good heat insulation: due to its lightweight, low thermal conductivity and water absorption but high coefficient of energystorage, together with its high obturator rate over 95%, it enjoys good thermalinsulation performance and is the ideal materials used for heat, thermal andsound insulation currently.

3. High compressive strength and strong bindingpower: compressive strength > 0.5MPa; good compatibility; high adhesion towall; low value on dry and contracts; high wind resistant, without swells andcracks.

4. The same life cycle with buildings:Currently, most of the thermal insulation materials’ life is about 20 to 25years or even shorter. The cost of the second and the third construction willbe much higher which always does great harm to the environment as well as tohuman life and production. But this product is stable and anti-carbonized,aging, freezing resistance with weather-proof, whose life can be as long as thebuildings, hence the full-life cost is much lower.

5. Easy construction and short-timeconstruction: Directly to use special mortar to plaster is very easy. And tostart the construction simultaneously can greatly shorten the constructionperiod.

6. Non-toxic and harmless, green andenergy-saving: made of original materials such as cement and fly ash, it canstay non-ignitable and non-toxic under high temperature. It is safe andenvironmentally friendly and can be used as recycling product supported bynational industrial policy.

III. Executive standard:

Regulations on the Application Technology of the External WallThermal Insulation System of the Composite Foaming Cement Panel (SU JG/T041-2011)

VI. Precautions:

1. Before paving the panel, you should clearthe surface dust.

2. The paving of the panel should start fromthe first floor, and the level line should be 300mm away from the plinth groundfrom the bottom to up horizontally and transversely to pave it. The staggeredjoints between panels of upper and lower rows should be 1/2 the panel length.

3. The paste between the panel and the basicwall should be with no space left. An iron float should be used to coat every panelwith a layer of over 3mm adhesive mortar evenly when pasting, and the pastingarea should be more than 95%. You should paste and press the mortar to the basetimely and to make sure that the gap of joint between panels should be no largethan 1mm.

4. When composite foaming cement panel is inthe corner of wall, you should pre-arrange the dimension and cut it to a propersize and vertically connect them in cross shape to ensure its perpendicularitywith the corner.

5. When pasting the external corners around thewindow frame and the outer corners of wall, you should stretch out the verticalbaseline to ensure the perpendicularity of the external corners. And the foamingcement panels to be pasted to the door and window edges should be cut into “L”shape and no split joint should be allowed. The gap between joints and windowedges should be no less than 100mm.

Contact Us

- Xuzhou Singular Building Materials Technology Co., Ltd

- Contact nameAmy Lee Chat Now

- Phone86-516-85026192

- AddressTianjing Road Tongshan Area, Wenzhou, Zhejiang

Product Categories

| New product |

New Products

-

ZM-3C Polycarboxylate Efficient Pumping Aid

-

ZM-4 Polycarboxylate Superplasticizer

-

ZM-4B Polycarboxylate Superplasticizer

-

ZM-5 Retarding Superplasticizer (Setretarder superplasticizer)

-

ZM-5B Concrete Early Strength Agent (Concrete Hardening Acceleratar)

-

ZM-6 Expanding Agent (Concrete Multi-Purpose Expansion Agent)

Popular Searches

- caustic soda flake

- sodium hydroxide

- caustic soda

- chelate agent

- activated carbon

- activated charcoal

- active carbon

- anthracite filter media

- granular activated carbon

- coconut shell activated carbon

- powder activated carbon

- nut shell activated carbon

- honeycomb activated carbon

- coal activated carbon

- wood activated carbon

- activated charcoal carbon

- silicone surfactant

- molecular sieve

- silica gel

- alumina ball

- zeolite molecular sieve

- molecular sieve adsorbent

- silica gel adsorbent

- molecular sieve desiccant adsorbent

- activated carbon adsorbent

- molecular sieve zeolite adsorbent

- silicone rubber

- silicone material

- silicon gel

- cleaning agent

Recommended Products

- High-Quality RDP: Anti-Caking and Reliable Alternative to Vinnapas 5010N

- HIFULL Hydrophobic Fumed Silicon Dioxide Nanoparticles HB-202N Sio2 Fumed Silica Powder Manufacturer Price

- HIFULL High Purity HB-701 Dental Composite Resins Nanoscale Hydrophobic Fumed Silica Powder Super Fine Silicon Dioxide Coating

- HIFULL Hydrophilic Fumed Alumina for Lithium Battery Separator Nano Grade Fumed Aluminum Oxide Granules Aluna-100

- HIFULL Nano Grade Hydrophilic Anatase Rutile Mixed Crystal Structure Tio2 NT-50 P25 Hydrophilic Fumed Titanium Dioxide

- HIFULL Industrial Grade Hydrophobic Fumed Silica Powder HB-615 Fine Nanoparticle Pyrogenic Silica Liquid Coating Factory Price

- HIFULL Industrial Grade HMDS Treated Hydrophobic Fumed Silica HB-612 Nano Silicon Dioxide Powder White Carbon Coating Rubber

- HIFULL HL-450 Amorphous Hydrophilic Fumed Silica Sio2 Nano Particles Silicon Dioxide Reinforcing Filler Powder Coating

- Hot Sale Hydrophilic Fumed Silica HL-150 Nano Silicon Dioxide Thickening Epoxy Resin with BOM/One-stop Service

- HIFULL HTV LSR Reinforcing Filler Nanoscale White Carbon Black Hydrophilic Silica (Pyrogenic Silicon Dioxide) Hydrophilic Powder

- HIFULL HL-90 Nano Silica Amorphous Colloidal Silicon Dioxide Powder Fumed Silica Nanoparticles for Rubber Synthesis

- HIFULL Hydrophilic Fumed Silica Powder Nanoscale Food Grade Oxide Free Flow Aid FA35 White Carbon Black Silica Dioxide Particles

Find Similar Products By Category

- Chemicals > Chemical Auxiliary & Catalyst > Chemical Auxiliary

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Amy Lee

Hi there! Welcome to my shop. Let me know if you have any questions.

Amy Lee

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile