How to Use Repair Strip Correctly?

We know when conveyor belt damaged , scratched or torn, we have to repair it with repair strip,

but how to use repair strip correctly and efficiently? Definitely, to a new comer in the repair

industry, you will need a guidance.

Meanwhile, in the forward passage “conveyor belt repair”, we have introduced how to repair a

conveyor belt, you can take a check.

Methods for rubber conveyor belt repair

1. First of all, we will mark the damaged parts,this is for choosing the appropriate repair

strip, we will cut the repair strip according to the size of damaged parts, make sure that repair

strip should be 4cm larger than the damaged parts.

2. Use the angle grinder L1202 accompany with tungsten carbon buffing disc to grind the damaged

parts, grinding parts should present a certain radian and no protrusion points.

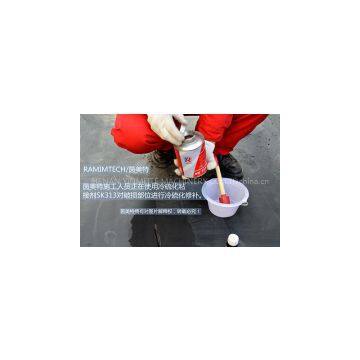

3. Mix cold vulcanizing glue SK313 with hardener according the ratio 100:4, grinding parts should

brush the mixture twice, first brush should be entirely dry(at least 30 minutes, however the

metal surface at least need a hour). Then the second brush. However the repair strip should brush

once only, when both of them have little stickness ( test with finger back), we can glue them.

4. Repair strip should glue along with the marked line from one side to the other side, after

finishing all, use the roller stitcher press from inside to outside, after compaction, we can

realize the repair.

Attentions:

1. If the damaged parts sunken seriously, we will advice filling them with T2 system, then use

the repair strip.

2. Conveyor belt repair parts should brush the cold vulcanizing adhesive mixture twice and repair

strip whose semi-cured layer will brush once only.

3. Cold vulcanzing adhesive Sk313 and hardener will mix according to 100:4, and the amount will

choose according to the size of damaged parts and avoid the Sk313 solidify and waste.

Send Inquiry to This Supplier

You May Also Like

-

Thermoplastic Polyurethane TPU Resin For Printing Ink TPU GranulesUS$ 2.22MOQ: 1 Kilogram

-

50ml Loctite Screw Glue 290 Penetrating Medium Strengthanti-loose Metal Thread Locking Agent 222 243 242NegotiableMOQ: 1 Bag

-

High Grade Construction Hot Melt Adhesive for Baby DiaperUS$ 2.8 - 3.2MOQ: 1 Ton

-

2016 Zhengzhou Factory Natural Artificial Stone Mold for Making Artificial StoneUS$ 1 - 30MOQ: 1000 Pieces

-

Hot Seal de High Quality Silicon Rubber Bushing From China O RingsUS$ 0.1 - 10MOQ: 100 Pieces

-

Non-asbestos SheetNegotiableMOQ: 1 Kilogram

-

Brand Casual Seventh of the Exercise Bike Pants Digital Print CustomNegotiableMOQ: 1 Kilogram

-

Structure SealantNegotiableMOQ: 1 Kilogram

-

Rubber ProductsNegotiableMOQ: 1 Kilogram

-

Silicone SealsNegotiableMOQ: 1 Meter