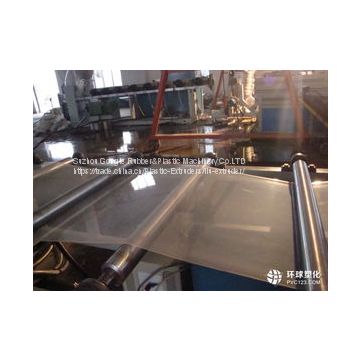

about plastic pet sheet making machine extrusion line

It is the production line of the most advanced technology, most mature crafts and one of the most stable machines, its comprehensive capacity is 30% higher than the domestic similar equipment. The production line is used to produce PS, PP, PE etc. sheet products. Qingdao Xinquan plastic machinery has developed the CPET Sheet production line which is still higher than the domestic technology. The PET crystallization and drying system has absorbed the most advanced international technology, has the advantages of low dew point, low energy consumption, this highly enhance the performance of the complete production line.

Application: PET (APET, PETG, and CPET) sheet has the advantages of good processability, transparent, insulation and innocuity, environment friendly and recyclable. It is used to the food packaging field, is a perfect product to replace the PVC product.

Model | Single-layer PET sheet production line | Single-layer PET sheet production line | Multi-layer PET sheet production line |

Model of extruder | SJ-120/33 | XQ-75/36 | SJ-120/33 SJ-65/33 |

Width of product | 500-1200mm | 500-1200mm | 500-1200mm |

Thickness of product | 0.2-1.2mm | 0.2-1.2mm | 0.2-1.2mm |

Motor power | 132kw | 75kw | 132kw/45kw |

Max. extrusion capacity | 350kg/h | 250 kg/h | 400 kg/h |

Production line speed | 5-20m/min | 5-15m/min | 5-25m/min |

Outline of the Kneader Sheet Preformer

The Kneader sheet preformer was designed to manufacture rubber sheets on a fully automatic basis. This uniquely designed sheet preformer consists of two sections, a twin taper screw feeder and a roller die unit. The feeder section has a large volume hopper, which is capable of handling multiple batches directly from a mixer. The twin taper screws “bite” and feed the rubber compound into a horizontal roller die for automatic and continuous sheeting, while large volume cooling jackets in the feeder and roller die section imparts effective cooling to the rubber compound. The unit function as replacing mixing mill, and it reduces cost and improves working efficient.

Features of PET Sheet Making Machine

1. Automated sheet production

2. Consistent material feed to rolls

3. Excellent sheet cooling capabilities

4. Produce sheet with less energy costs

5. Self cleaning – no residual material left in feeder section

6. Reduced wear (no feed screw to casing contact)

7. Improves compound uniformity

Send Inquiry to This Supplier

You May Also Like

-

Good Quality Stone Paper Making MachineUS$ 1000000 - 2000000MOQ: 1 Set

-

201180906 High Technical Process Foam Xpe Baord Making MachineUS$ 5000 - 15000MOQ: 1 Set

-

PE/PP/XPE/EVA+Silicon Rubber Foaming Sheet Making Machine LineUS$ 5000 - 15000MOQ: 1 Set

-

2018 High Quality Xpe Eva Foam Sheet Production Machine(extruder +3 Rollers Calender Machine)US$ 5000 - 65000MOQ: 1 Set

-

2018XPE Yoga Mat Sheet Making Machine(extruder +3 Rollers Calender Machine)US$ 5000 - 65000MOQ: 1 Set

-

20180830 Heat Resistant XPE pe Foam Insulation Sheet Making Machine(extruder +3 Rollers Calender Machine)US$ 5000 - 65000MOQ: 1 Set

-

20880901 Good Quality Eva XPE Chilren Playground Mat Sheet Making Machine(extruder +3 Rollers Calender Machine)US$ 5000 - 65000MOQ: 1 Set

-

2021TPE/XPE/PVC/NBR/EVA Foam Yoga Mat Making Machine(extruder+3 Rollers Calender Machine)US$ 5000 - 65000MOQ: 1 Set

-

20180829 Automatic PP PE ABS PMMA PC PS Plastic Sheet Production LineUS$ 5000 - 60000MOQ: 1 Set

-

201808082EPE XPE IXPE IXPP Foam Plastic Sheet SANDWITCH LAMINATOR MACHINEUS$ 5000 - 65000MOQ: 1 Set