Car Decoration Sheet Eva Sheet Rpoduction Line(extruder +3 Rollers Calender Machine)

For this end product, we have two process: one is kneader dispersion mixer +single screw extruder ,the other is twin screw extruder, w e should recommend the suitable one for you according to your endproduct.

Professional Manufacturer of Plastic Extruding Machine :

Plastic Extruding Machine of Conical Twin Screw Extruder:

. Advanced screw design to ensure high-speed extrusion of PVC pipe;

. Reliable temperature control system to ensure the production of high quality PVC pipe.

Plastic Extruding Machine of Mold:

. Spiral mold make product quality better

. The internal heating control system is more convenient, more efficient for extrusion

. Precise tin bronze or phosphor bronze sizing sleeve hold features of pipe cooling and sizing fast.

Plastic Extruding Machine of The Spray Cooling Equipment:

. The device center height can be adjusted;

. Water tank length 6m-8m, effective and efficient for cooling.

Plastic Extruding Machine of Traction Device:

.The precise pressure regulating system can adjust the traction

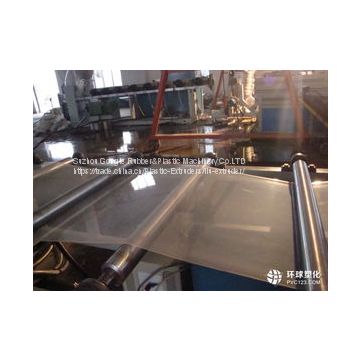

Widely used rubber and plastic sheet extrusion calendering line

the process : kneader dispersion mixer - cone double feeding machine - single screw extruder--- brace head and net exchanger--sheet mold --3 rollers calender --cooling stacker--sheet cutter

Performance introduction:

1.The Wide width rubber sheet extrusion line is mainly composed of cold feeding pin extruding system, the double-roll calendering system, the six-roll cooling system, the rubber sheet combining system, double-station packing system, etc.

2.The rubber cover of conveyor belt is produced in the following procession, the fully plasticating in the pin-extruder, and then the passing from the extruding die with the help of the double-roll calendering system.

3.The cover wide width of less than 2600mm and thickness of 1.5~1.8mm, is produced without the problem of bubble and fish scale in this procession. And also the additional function, such as rubber covering on the flame retardant belt, can be realized if the production line is equipped with other necessary device.

| Contact | Conrad Liu |

| Address | Qiandeng near Shanghai airport |

| Contact person | Conrad Liu 0086 13511639912 |

| Address | Qiandeng Town, near Shanghai Airport |

Send Inquiry to This Supplier

You May Also Like

-

Sandwich Glass Layer EVA PVB Casting Film Extrusion MachineUS$ 5000 - 60000MOQ: 1 Set

-

Good Quality Stone Paper Making MachineUS$ 1000000 - 2000000MOQ: 1 Set

-

201180906 High Technical Process Foam Xpe Baord Making MachineUS$ 5000 - 15000MOQ: 1 Set

-

PE/PP/XPE/EVA+Silicon Rubber Foaming Sheet Making Machine LineUS$ 5000 - 15000MOQ: 1 Set

-

2018 High Quality Xpe Eva Foam Sheet Production Machine(extruder +3 Rollers Calender Machine)US$ 5000 - 65000MOQ: 1 Set

-

2018XPE Yoga Mat Sheet Making Machine(extruder +3 Rollers Calender Machine)US$ 5000 - 65000MOQ: 1 Set

-

20180830 Heat Resistant XPE pe Foam Insulation Sheet Making Machine(extruder +3 Rollers Calender Machine)US$ 5000 - 65000MOQ: 1 Set

-

20880901 Good Quality Eva XPE Chilren Playground Mat Sheet Making Machine(extruder +3 Rollers Calender Machine)US$ 5000 - 65000MOQ: 1 Set

-

2021TPE/XPE/PVC/NBR/EVA Foam Yoga Mat Making Machine(extruder+3 Rollers Calender Machine)US$ 5000 - 65000MOQ: 1 Set

-

20180829 Automatic PP PE ABS PMMA PC PS Plastic Sheet Production LineUS$ 5000 - 60000MOQ: 1 Set