Specially Designed Paddle Dryer for Chemical Sludge Drying Turnkey Service!

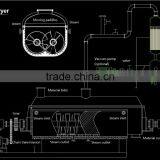

Paddle dryer is an indirect drying equipment with hollow paddles/blades installed usually in a horizontal hollow axle rotating in a vessel. the wet feed is dried when the rotating paddles stir the materials and resulting in a close contact with the heated paddles and vessel shells. The dryer has a high heating transfer surface and high heat efficiency due to no heat loss in exhaust gas(only heat loss is radiation via heavily insulated dryer vessel, which is very trivial). The paddles are self-cleaning due to relative motion between the wet feed and the wedge-shaped paddles. Paddle dryer can work in batches or continuously, in vacuum, protective atmosphere or pressure conditions according to drying requirements and nature of wet feeds. The heating medium can be thermal oil or hot water with pressure from 0.1 MPa to 0.8 MPa, Steam with pressure up to 1.5 MPa. Working temperature: 40 C to 300 C. Evaporation capacity: 8Kg to 60Kg/m2.h

Main features:

1.Low energy consumption. Indirect heating, no heat loss due to exhaust gas; minimum heat loss via radiation due to heavily insulated Dryer body. Only 1.2kgs of steam is required to vaporize 1 kg of water.

2. Low manufacturing cost, huge heat transfer area per unit volume, feed dwelling time and dryer sizes can be less, therefore less floor area and smaller workshop is required.

3. Suitable to dry a wide range of materials, heat-sensitive material can be handled with the right heating medium, meanwhile it can also work under high temperature process other materials. Heating medium can be steam, hot water, thermal oil, cold water, etc.. it can work in batches or continuously.

4.minimum environmental pollution: Enclosed process, no fugitive gas

5. low operating &maintenance cost.

Technical Data of paddle dryers

Model |

DLP-3 |

DLP-9 |

DLP-13 |

DLP-18 |

DLP-29 |

DLP-41 |

DLP-52 |

DLP-68 |

DLP-81 |

DLP-95 |

DLP-110 |

Heat transfer area, m2 |

3 |

9 |

13 |

18 |

29 |

41 |

52 |

68 |

81 |

95 |

110 |

working volume, m3 |

0.06 |

0.32 |

0.59 |

1.09 |

1.85 |

2.8 |

3.96 |

5.21 |

6.43 |

8.07 |

9.46 |

rotating speed, r/m |

15 to 30 |

10 to 25 |

10 to 25 |

10 to 25 |

10 to 20 |

10 to 20 |

10 to 20 |

10 to 20 |

5 to 15 |

5 to 15 |

5 to 10 |

Power, kw |

2.2 |

4 |

5.5 |

7.5 |

11 |

15 |

30 |

45 |

55 |

75 |

95 |

Total width, mm |

736 |

841 |

1066 |

1320 |

1474 |

1676 |

1854 |

2134 |

1186 |

2438 |

2668 |

Total length, mm |

2972 |

4876 |

5486 |

5918 |

6808 |

7570 |

8306 |

9296 |

9678 |

9704 |

9880 |

Size between material inlet & outlet, mm |

1752 |

2540 |

2768 |

3048 |

3810 |

4420 |

4954 |

5384 |

5562 |

5664 |

5664 |

Total height, mm |

762 |

838 |

1092 |

1270 |

1524 |

1778 |

2032 |

2362 |

2464 |

2566 |

2668 |

steam inlet, inch |

3/4" |

3/4" |

1" |

1" |

1" |

1" |

1 1/2" |

1 1/2" |

11/2" |

1 1/2" |

2" |

water outlet, inch |

3/4" |

3/4" |

1" |

1" |

1" |

1" |

1 1/2" |

1 1/2" |

1 1/2" |

1 1/2" |

2" |

Evaporation capacity |

8Kg/ m2.h to 60Kg/m2.h |

||||||||||

Working temp. |

40 C to 300 C |

||||||||||

Heating Media |

thermal oil/hot water with pressure from 0.1 MPa to 0.8 MPa or steam with pressure up to 1.5 MPa |

||||||||||

1. Free consultation on technical &commercial issues, provide market evaluation, project feasibility based on each customers' condition.

2. Provide free drawings at no cost for factory layout, piping & wiring systems, installation plannings,

3. Free installation, commissioning and operation training services at no costs to customers.

4. 24/7 aftersales service, free of charge if repair service required within 1 year after installation.

Send Inquiry to This Supplier

You May Also Like

-

FREE Installation and Training! Turnkey Service Cassava Waste Dryer!US$ 66,000 - 66,000MOQ: 1 Set

-

FREE Installation and Training! Turnkey Service Rotary Drum Type Cassava Dregs Dryer!US$ 66,000 - 66,000MOQ: 1 Set

-

Electric Gas Heating Small Mini Type Mobile Grain Dryer!US$ 66,000 - 66,000MOQ: 1 Set

-

FREE Installation and Training! Turnkey Service Sweet Rotary Drum Potato Waste Dryer!US$ 66,000 - 66,000MOQ: 1 Set

-

Turnkey Service Rotary Drum Type Sweet Potato Dregs Dryer!US$ 66,000 - 66,000MOQ: 1 Set

-

Turnkey Service Rotary Drum Type Sweet Potato Residue Dryer!US$ 66,000 - 66,000MOQ: 1 Set

-

Turnkey Service Good Price Rotary Drum Type Pomelo Residue Dryer!US$ 66,000 - 66,000MOQ: 1 Set

-

Turnkey Service Good Price Rotary Drum Type Grapefruit Residue Dryer!US$ 66,000 - 66,000MOQ: 1 Set

-

Free Installation and Training Rotary Drum Type Exhausted Beet Pulp Dryer!US$ 66,000 - 66,000MOQ: 1 Set

-

Free Installation and Training Rotary Drum Type Sugarbeet Pulp Dryer!US$ 66,000 - 66,000MOQ: 1 Set