Ceramic Proppant Equipment of Bauxite Rotary Kiln for Bauxite Calcination

Ceramic proppant equipment of bauxite rotary kiln for bauxite calcination

Bauxite ore introduction:

Bauxite, an aluminium ore, is the world's main source of aluminium. It consists mostly of the minerals gibbsite Al(OH)3, boehmite γ-AlO(OH) and diaspore α-AlO(OH), mixed with the two iron oxides goethite and haematite, the clay mineral kaolinite and small amounts of anatase TiO2.

Usually, bauxite ore is heated in a pressure vessel along with a sodium hydroxide solution at a temperature of 150 to 200 °C. At these temperatures, the aluminium is dissolved as sodium aluminate (the Bayer process). The aluminium compounds in the bauxite may be present as gibbsite(Al(OH)3), boehmite(AlOOH) or diaspore(AlOOH); the different forms of the aluminium component will dictate the extraction conditions. The undissolved waste, bauxite tailings, after the aluminium compounds are extracted contains iron oxides, silica, calcia, titania and some un-reacted alumina. After separation of the residue by filtering, pure gibbsite is precipitated when the liquid is cooled, and then seeded with fine-grained aluminium hydroxide. The gibbsite is usually converted into aluminium oxide, Al2O3, by heating in rotary kilns or fluid flash calciners to a temperature in excess of 1000oC. This aluminium oxide is dissolved at a temperature of about 960 °C in molten cryolite. Next, this molten substance can yield metallic aluminium by passing an electric current through it in the process of electrolysis.

Ceramic sand also called ceramic proppant, hydraulic fracturing sand, oil fracturing proppant, ceramic sand, bauxite ceramic proppant, bauxite proppant, is used in the construction of deep well fracturing to increase the oil and gas production output as well as to extend the oil and gas well’s service life.

High-strength density of type

Type Ⅰ 0.45-0.9mm (20 mesh -40 mesh) high-intensity medium density

Type Ⅱ 0.9-1.25mm (16 mesh -20 mesh) high-intensity medium density

Type Ⅲ 1.0-1.70mm (12 mesh -18 mesh), medium density high strength

Type IV 0.224-0.65mm (40 mesh -60 mesh) high-intensity medium density

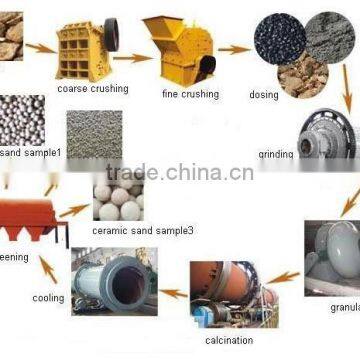

Bauxite will be firstly crushed by jaw crusher and hammer crusher and then it will be conveyed to batching silo.

After batching with other material, materials will be sent to ball mill and grinded into powder. Classifier will be used after ball mill for size grading. Here raw material will be sent to silo again.

Then raw material will go to granulator and will be made into different size pellets. Pellets will be sent to screening equipment. Qualified size pellets will be conveyed to rotary kiln for calcination. Oversize pellets will be sent back for grinding.

After pellets calcined in rotary kiln, we get qualified product ceramic sand. At last, ceramic will go to cooler for cooling. And will go to screen to get different size oil fracturing proppant and will be packed in ton bag. The production process ends.

Structure: Ceramic proppant equipment is composed by rotary body, lifting blade,driving device, supporting device and sealing ring.

Ceramic proppant equipment working site:

Derui Intorduction:

Derui machinery Co., Ltd. is a China-based high-technology heavy machinery manufacturer, which engaged in R&D, production and sales of machinery. Our main products include mill grinding machine, rotary dryer, mineral processing equipment, dryer equipment, stone crusher machine, sand and stone production line,Ceramic proppant equipment.

How to visit us ?

If you want to visit our factory, please note our city name, Zhengzhou City, Henan Province, China(mainland)

Our air port name is : Zhengzhou Xinzheng International air port.

Train station name is: Zhengzhou (Zhengzhou north) train station

Send Inquiry to This Supplier

You May Also Like

-

Multi-function Powder Mixing Equipment Stainless Steel U-typed Powder Blender Flour Double Screw Mixer With CEUS$ 880 - 2290MOQ: 1 Set

-

Trommel ScreenNegotiableMOQ: 1 Piece

-

Factory Supply Cco Plate Mixed Concrete Batching Plant Wear Resistant LinersUS$ 500 - 500MOQ: 1 Set

-

Supply 4*2 DFAC Light Truck Mixer Truck 6cmb Cement Mixer TruckNegotiableMOQ: 1

-

Solids Control Industry Desanding EquipmentNegotiableMOQ: 1 Set

-

Exported to Mongolia the Complete Cement Making LineUS$ 50,000 - 150,000MOQ: 1 Set

-

130T/H ROADY RD125New Asphalt Hot Mixing PlantUS$ 10,000 - 1,000,000MOQ: 1 Set

-

Polishing Machine RotomouldingNegotiableMOQ: 1

-

Automatic Ready Mixed Concrete Batching Plant Factory Concrete Admixture Mixing Plant New Technology Concrete Batch PlantUS$ 500 - 2,000MOQ: 1 Set

-

Good Stability & High Efficiency HZS50 Concrete Plant Twin Shaft MixerUS$ 50,000 - 150,000MOQ: 1 Set