Gold processing plant of flotation machine for gold concentrate

Gold has three categories, gold ore (Mountain gold mine, endogenous gold) and gold placer (alluvial, alluvial, beach type, slope deposits type and exogenous gold) and Associated gold (recovery from the non-ferrous minerals )

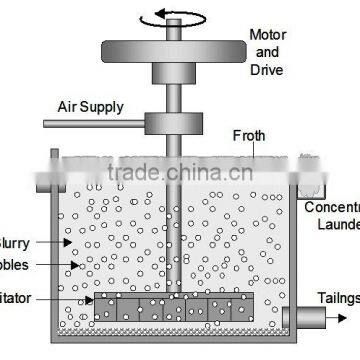

Flotation machine is also known as flotation cell and flotation tank, which is one kind of ore processing equipment mainly used to separate copper, zinc, lead, nickel, gold, silver, lead and other non-ferrous metals. So, it is also called gold flotation machine and copper ore flotation machine.

Working Principle of SF flotation machine:

When it works, the motor drives the impeller to revolve, so the centrifugal effect and negative pressure are produced. On one hand, ample air is absorbed and mixed with mineral slurry, on the other hand, the mixed mineral slurry is mingled with additive, meanwhile, the foams are thinning, the mineral is bounded with foams, and floats up to the surface of mineral slurry and the mineralized foam is formed. The liquid surface can be adjusted with the height of adjustment flashboard, so that the useful foams are scraped with squeegee.

Technical parameter of SF flotation machine:

Gold Extraction and Beneficiation:

1. Transport the gold ore to gold beneficiation line;

2. Inspect the gold ore, including its hardness, sulfur content, carbon content and other minerals components, then choose the right beneficiation mothed ;

3. Sent gold ore into crushers (jaw crusher, impact crusher, cone crusher, etc.) and grinding mills (ball mill, etc.) to break and make smaller sizes, then tranport the crushed gold ore to gravity separator or flotation machine;

4. Gravity separation is widely used in the rock gold mine, and create good conditions to flotation and cyanidation process, which can improve the beneficiation indicators, improve recovery rate of gold, gravity separator plays a positive role for increasing production and reduce cost;

5. Flotation machine process or a weak cyanide solution to the slurry, this process can extract 93% of the gold and 70% of the silver from the ore. And then the gold is pulled from the solution and attaches to the carbon. Then "strip" the gold from the carbon by washing it with a caustic cyanide solution. And the carbon can beis recycled after this;

6. Pump the gold-bearing solution through electro-winning cells to extract gold metal from the solution by an electrical current;

7. Smelt the gold in a furnace at about 2,100°F. and the molten gold is poured into molds.

8. Send the bars to a refinery for further processing into pure gold.

Application of Gold:

Gold is a precious and luxury metal extracted from gold ore to make treasure and ornament. The gold concentrate can be melted and cast into almost any shapes to make jewelry. There are numerous industrial applications for gold. As well, many electronics and medical devices need gold to conduct electricity and resist corrosion.

How to visit us ?

If you want to visit our factory, please note our city name, Zhengzhou City, Henan Province, China(mainland)

Our air port name is : Zhengzhou Xinzheng International air port.

Train station name is: Zhengzhou (Zhengzhou north) train station

Send Inquiry to This Supplier

You May Also Like

-

Wet Drum Permanent Magnetic SeparatorNegotiableMOQ: 1 Set

-

Trommel Gold Washing Machine Rotate Scrubber WasherUS$ 3,000 - 6,000MOQ: 1 Set

-

Match With Tunnel Boring Machine Separation PlantNegotiableMOQ: 1 Set

-

Alluvial Gold Sand Movable Gold Trommel MachineUS$ 2,000 - 50,000MOQ: 1 Set

-

Ceramsite Linear Vibration Sieve/seapratorUS$ 1,000 - 6,000MOQ: 1 Set

-

Gold Ore Wet Pan Mill/Pan Mill/Wet Grinder for Saudi Arabia MarketUS$ 1 - 10,000MOQ: 1 Set

-

3 Inch Mini Gold Mining Dredge With Lightest WeightUS$ 2,000 - 4,000MOQ: 1 Set

-

First-rate High Efficiency SZZ Series Self-centering Vibrating Screen With ISO 9001 CertificateUS$ 2,500 - 55,000MOQ: 1 Set

-

Vibrating Sieve for SaltUS$ 2,647 - 2,700MOQ: 1 Set

-

Belt Conveyor Magnetic SeparatorUS$ 7,500 - 10,000MOQ: 1 Set