Hot sell Best price mini flour mill

We can offer single flour milling machine from 7t/24hr to 18t/24hr for mini flour mill plant

This series includes 6FS-7A, 7B, 9A, 9B, 12A, 12B, 15A, 18A

About the Diamond Brand

--- 65 years experience in flour mill industry

--- Best solution for wheat and maize processingsystem

--- The biggest flour mill machine manufacturer and exporter in China

--- Exporting to more than 40 countries with a presence world wide.

--- High quality and efficiency technology

The competitive advantage of product line:

Output Index for wheat flour milling machine :

special grade flour about 65%-75%(Adjustable)

standard grade flour about 80%(Adjustable)

1. Produce type: special grade No. 1 flour, special grade No. 2 flour, standard flour, middling products;

2. Power consumption: 60 kwh/ton wheat;

3. Yield: Special grade No.1: 65%, Special grade No.2: 75%, standard flour: 80%, midding flour: 3-5%, bran: 15-20%;

Final product quality parameter for wheat flour milling machine :

1. Fineness of the flour: 80-150 mesh

2. Magnetic metal content: not more than 0.003g/kg;

3. Sand content: less than 0.002%;

4. Water content: moisture: 13.5-14.5;

Our Advantages

| 1 | We provide a turnkey project for home use automatic wheat flour mill. |

| 2 | Suitable design according to clients' requirements. |

| 3 | Advanced technology and reliable quality for wheat and maize processing system. |

| 4 | Steel instructure or floor instructure for mini flour mill plant |

| 5 | Professional engineers will be responsible for installation and training staffs. |

| 6 | Good quality & competitive price for small scale milling plant |

| 7 | Lifelong service |

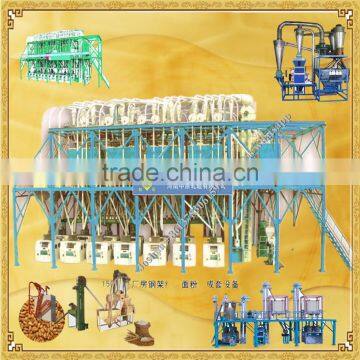

Processing Line

Complete set of home use automatic wheat flour mill can be divided into four parts: cleaning part, milling part, packing part and PLC controlling part or manual electric cabinet.

1. Cleaning part

to clean out the middle and small impurity from wheat/maize. e.g., dust, stone, magnetic material, wheat/maize was bitten by insect and so on. Includes beating, screening, destoner, magnetic separator and dampening. This section is to prepare for milling part and to protect the machinery as well.

2. Milling part

The second step, to mill the grain and separate the flour, bran and other by-product:

(1) Mill: mill the grain to break the integrity by the roller moving

(2) Sifter: to separate the flour, bran and other by-product, also separate large size and small size to ensure wheat flour quality.

3. Packing part

The third step, the packing machine can be manual or automatic weighting and packing 1kg-50kg/bag, pp woven bag or paper bag.

4. PLC controlling system

PLC controlling system is mainly used in big flour mill plant to controlling the whole set of machinery to work well and showing the process of working.

Send Inquiry to This Supplier

You May Also Like

-

Hydraulic Cold Press Cocoa Butter Sesame Seed Coconut Olive Avocado Oil Process Pressing Extraction MachineUS$ 1350.00 - 1400.00MOQ: 1 Set

-

Stable Working Milk Defatter / Cream Milk Separator / Skimming Milk Machine For MilkNegotiableMOQ: 1 Set

-

GELGOOG Automatic Chocolate Mini Cone Line|Ice Cream Cone Production LineUS$ 30000 - 100000MOQ: 1 Set

-

Public RelationsNegotiableMOQ: 1 Set

-

MANPOWER SUPPLY ServiceNegotiableMOQ: 1 Set

-

Titanium DioxideNegotiableMOQ: 1 Set

-

TapNegotiableMOQ: 1 Set

-

Recycled RubberNegotiableMOQ: 1 Set

-

Sell Men's Business SuitNegotiableMOQ: 1 Set

-

2017 SENY New Small Maamould Encrusting Machine Industrial Sweet Food Processing MachineUS$ 200 - 5,888MOQ: 1 Set