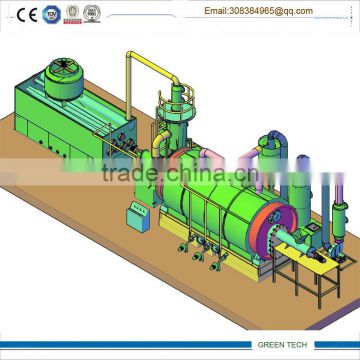

Fast Installation Plastic and Tyre Waste Pyrolysis Recycling Line

15Ton Wate tyre pyrolysis plant convert tyre waste to oil ,after pyrolysis we get

35-50% fuel oil

10-15% steel wire

30-35% carbon black

Reactor will be loaded on 40FR container

loading in 40HQ Container

small parts in wooden box

.

Payment term and delivery:

30% TT deposit, balance paid by Sight LC/ 100% Sight L/C

Delivery with 15-20 days after getting advance payment or Sight L/C

Pre-sale service:

1.Our engineer offer project report help you analysis cost and profit,and advise customer suitable type plant and details.

2.Take customers visit running plants.

On-purchase service:

1.Once get advance payment, we will offer layout and detailed art-work drawings and detailed machine lists.

2.Help users booking ship.

After-sale service:

1. Delivery time-- It will be within 15 working days after we receive the deposit.

2. Warranty- The warranty period is 2 Years(Other suppler offer 1 year warranty), engineers available to service at any time.

3. Installation and Training-- Our Company will dispatch technician to guide installation and training for free, ensuring the operation safety. The installation period shall be one month; otherwise, buyers will pay extra salary for the technician with the price of USD 60.00 per day.

4. 24-Hours telephone service .

Regular phone visiting to check out if there is anything we can do for you, maintenance guiding, easily worn-out parts and catalyst offering, on-site maintenance.

5.Up-date technology will inform our users and help them update plant.

6.Documents of operation manual and matters need attention will be offered to users.

7.Offer catalyst formula for free, training oil treatment skills for free.

Remarks:

A. we can produce machine according to your requirements.

B. Delivery time can be shorten according to your requirement.

C. We can offer other vicinity device according to your requirement.

1. FUEL OIL

It is the main product from the oil produce of pyrolysis process, widely used for industrial

and commercial purposes. Fuel oil composes of 45% to 53% of the total output.

1. CARBON BLACK

Carbon Black is the main product recycled by pyrolysis technology. The amount of recycled

carbon black is 30-35% (depend on the type of tyre) of the total amount of scrap tyres recycled

in the system. Carbon black can be used as raw material in many industries. We can further

process it and increase the mesh by grinding machine, or make it into carbon pellet by carbon

pellet machine.

2. GAS

Gases are the products that produced during the process of recycling. These gases are

non-condensable and occupy about 10% to 20% of the output.

Send Inquiry to This Supplier

You May Also Like

-

WL-1600 Garbage Shredder Household Waste Shredder MSW Recycling AmchineUS$ 55000 - 98000MOQ: 1 Set

-

High Efficiency Jinzhen 1~12 Ton Waste Plastic Pyrolysis to Crude Oil EquipmentUS$ 15,000 - 48,000MOQ: 1 Set

-

Rubber Powder Grinding Machine, Rubber Tire Recycling Machine for SaleUS$ 1,800 - 5,500MOQ: 1 Set

-

Forklift Solid Tire Press Machine 80T 100T 120 TUS$ 16 - 200MOQ: 1 Piece

-

High Output Bead Wire SeparatorUS$ 1,000 - 5,000MOQ: 1 Set

-

Fully Automatic Recycling Machine for Rubber PowderUS$ 34,000 - 114,000MOQ: 1 Set

-

In Stock Waste Tire Pyrolysis Plant for Tire OilUS$ 35,000 - 50,000MOQ: 1 Set

-

High Quality Hydraulic Car Tire Compress MachineUS$ 73,800 - 98,000MOQ: 1 Set

-

Salable PS Foamed Sheet ManufacturerUS$ 1,000 - 50,000MOQ: 1 Set

-

Rubber AccessoriesNegotiableMOQ: 1 Set