High quality hookah charcoal dryer from lantian

Brief introduction of charcoal dryer

Charcoal Briquette Dryer is a kind of drying equipment for batch ,continuous production.It is mainly used for drying plate ,strip ,and granular materials with better ventilation. Drying efficiency of this dryer is much higher than nature drying, and it is not influenced by weather. The dryer is applicable to food products or vegetables as well.

Working principle of charcoal dryer

1.The raw material was transported into the feeder and put on the mesh-belt uniformly. Then the transmission device will carry the mesh-belt to keep moving forward.

2.In the mesh- belt, there are some heater strips. When the fruit mesh belt dryer the power, the heater strips will produce great heat to dry the raw material.

3.The multil- ayers coal briquettes mesh belt is composed of several unit. Each unit is interlinked, so that the hot air can be successively used. And it can improve the drying effect.

4.The hot air alway around the surface of the raw material and turn water into water vapor, then the raw material complete the drying process.

5.At the top of the coke briquette belt dryer machine , there some small blowers. The small blowers will take the water vapor out and left the dried raw material.

Features of charcoal dryer

1. Health: whole sealing structure keeps the dust away from your goods

2. No fire risk: accurate control of temperature guarantee the safe of your goods

3. Various heat sources: coal, wood, electric can be used for energy

4. Alarm device: each machine is equipped with an alarm in case of accident

5. Excellent drying effect: this machine can dry your goods totally

6. Customized: we can design different types according to your requirement

Cusromer's visiting

The drying materials can be different shapes and sizes bbq charcoal, bbq coal, shisha charcoal, and other charcoal and coal briquettes. When you visit our factory, we will show you the details of our charcoal briquette dryer.

Information for other drying machine

We also have other types drying mahcine, include the rotary dryer, vertical dryer, sawdust dryer,belt dryer and so on. Every drying machine has different model number. You just tell me your raw materials, then i will recommend the suitable drying machine for you.

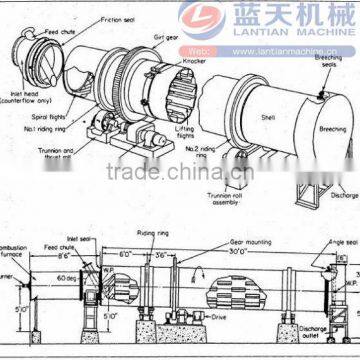

1.Rotary dryer can dry coal briquettes, sand, coal slime, fertilizer, sawdust, kaolin clay, fowl dung, and others. Its main parts are rotary body, heating source stove and dust removal device. The diameter and length of dryer can be customized according to customers capacity.

Installation of the hot air wood chip rotary dryer

1. The hot air wood chip rotary dryer should be loaded and installed on the level ground, better on the concrete floor, use foot screws fixed.

2. The roller body should be verticle on level ground.

3. After installation, we should check whether there is loose bolt and parts, then tighten it.

4. The hot air wood chip rotary dryer should be equiped with power cord and control switch.

5. Complete check, we should start the dryer without any materials in for about 3 minutes, if the dryer work well, we can put the materials for production.

Maintain of the hot air wood chip rotary dryer

1. We should add oil regularly. The lifetime of bearing is based on the good lubrication, which effect the lifetime and running rate of the rotary drum dryer. So we should cleaning oil and close them well. Some parts we should add oil is transmission bearing, rolling bearing, gears, moving bearing and slide plate.

2. The new installed tyre are easily loose, we should check them often.

3. Pay attention on whether every part of machine works normally.

4. Check the wearing degree of easy wear parts, and change the worn and damaged parts.

5. Remove the dirt of chassis plate where load the live device, in case of the live bearing can't move when there is materials not be broken appeared.

6. The temperature of bearing oil goes up, we should stop the machine and check.

7. If there is rushing sound when the rotating gear is running, we should stop the machine and check.

2.Vertical dryer is suitable for drying pellets, coal rod particles etc, such as coal balls, small pellets.

3. Sawdust dryer, we also called it indirect dryer, it means that when it is working, not directly and raw material contact, through heat conduction. Suitable for sawdust ,rice hull,milled Wheat straw, milled cotton, corn stalks, etc

4.Belt conveyor is especially suitable for the ventilation better sheet, strip, dry granular materials, paste materials on the cake, can also be obtained by granulating machine or extrusion molding after drying mechanism. Our customer use it for coal and charcoal briquette, small pellets.

Gongyi Lantian Machanical Plant is a coal/charcoal briquette equipments manufacturer and exporter in China. Our main products are coal/charcoal briquette equipments,shisha coal tablet press equipments,extruder equipments,sawdust/biomass briquette equipments,drying equipments and accessory equipments.

Send Inquiry to This Supplier

You May Also Like

-

China Factory Wholesale 500KW Industrial Electric Silent Power Diesel GeneratorNegotiableMOQ: 1 Set

-

Biomass Wood Sawdust Pellet Mill/Rice Huck Pellet Making Machine Peanut Shell Grass Straw Hay Pellet Press Maker Machine for Biomass Pellet ProductionUS$ 690 - 3880MOQ: 1 Set

-

Humic Acid Fertilizer Pellet Machine(CE)US$ 880 - 99,000MOQ: 1 Set

-

Pellet Briquetting Machine / Rice Husk Pellet Mill PriceUS$ 25,000 - 25,000MOQ: 1 Set

-

Wood Pellet Mill Machine for Wood Dust Pellet PressUS$ 1,000 - 10,000MOQ: 1 Set

-

Energy Saving Straw Coal Briquette MachineUS$ 2,000 - 3,000MOQ: 1 Set

-

Diesel Flat Die Small Pellet MillUS$ 500 - 1,000MOQ: 1 Set

-

Industrial Complete Flat Die Wood Pellet Production LineUS$ 20,000 - 25,000MOQ: 1 Set

-

Factory Directly Wood Pellet Press, Wood Pellet Press Machine, Gemco Supply Wood Pellet MillUS$ 3,000 - 4,000MOQ: 1 Set

-

Hot Sale and Best Quality Wood Briquette Machine Screw PressNegotiableMOQ: 1 Set