Specifications

Titanium iron ore beneficiation plant1. fine flotation rate

2. stable working conditions

3. high effiency

4. ISO9001, BV

Titanium Iron Ore Beneficiation Plant

Introduction of Titanium Iron Ore Beneficiation Plant

Henan Hongke Heavy Machinery can offer complete sets of selecting Titanium Iron Ore Beneficiation Plant.

The equipments of Titanium iron ore beneficiation plant cover feeders, crushers, screens, ball mill, conveyors, agition barrel, seperator, dryer and flotation, etc.

Brief Introduction of Titanium Iron Ore Beneficiation Plant

Titanium iron ore chemical formula: FeTiO3, mineral composition theory FeO47.36%, TiO2 is 52.64%, if the MgO-based mineral called magnesium in titanium, with titanium MnO manganese-based said the red. There magnetite ore in general, sulfide and other minerals.

Titanium iron ore beneficiation plant for the production of titanium dioxide is widely used in modern industrial white paint. It paints, paper and plastics for light-colored paint and advanced fillers, titanium total consumption of about 85%, while titanium dioxide is also used as chemical fiber matting, rubber packing, petrochemical catalyst, and ink, ceramics, glass, welding, metallurgy, electrical, artificial gems and new materials industries.

Also the production of titanium metal, titanium as an additive. Titanium and titanium alloy is to create a modern supersonic aircraft, rockets, missiles and space shuttle indispensable material.

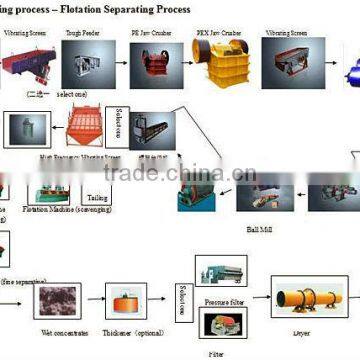

Working Principle of Titanium Iron Ore Beneficiation Plant

Titanium iron ore beneficiation plant include: “re-election – intensity magnetic separation — flotation” and “re-elected — Strong magnetic power selection (sorting before the addition of sulfur),” two kinds of dressing process to in strict accordance with fractionated selected, take a different process.

Titanium ore processing equipment, including: concentration levels ramp box (by size classification), wear-resistant spiral chute (abandoned tailings), the weak magnetic separator (except magnetic minerals), strong magnetic separator (Titanium iron), flotation (floating sulfide,titanium floating fine particles), electrostatic machine (selected ilmenite) and so on.

1. Titanium ore crushing process

China ore dressing plant generally use of coarse crushing, crushing in three sections of crushing and fine crushing of iron ore crushing process. Thick multi-1.2m or 1.5m breaking cycles crusher, breaking with 2.1m or 2.2m in the standard cone crusher, breaking the use of 2.1m or 2.2m fine short head type cone crusher. Through thick crushed ore, the block is not greater than 1m, and then after the fine crushing, screening the ore particle size less than 12mm into the final product sent to the grinding tank.

2. Titanium ore Grinding process

China Titanium grinding process uses two grinding processes, a small processing plant to use more grinding process. As a result of new technology fine sieve and then ground in recent years, some of the processing plant by two to three paragraphs grinding grinding. Titanium grinding equipment used in general relatively small, the largest mill 3.6m × 6m, the largest rod mill 3.2m × 4.5m, the largest since the mill 5.5m × 1.8m, pebble mill 2.7m × 3.6m. After grinding the classification is basically using the spiral classifier. In order to improve efficiency, some processing plant water power instead of the second cyclone spiral classifier.

We can offer complete sets of selecting copper, iron, gold, tungsten, etc equipments.

If you want to see more products about our company, pls link our website:

Send Inquiry to This Supplier

You May Also Like

-

Wet Drum Permanent Magnetic SeparatorNegotiableMOQ: 1 Set

-

Trommel Gold Washing Machine Rotate Scrubber WasherUS$ 3,000 - 6,000MOQ: 1 Set

-

Match With Tunnel Boring Machine Separation PlantNegotiableMOQ: 1 Set

-

Alluvial Gold Sand Movable Gold Trommel MachineUS$ 2,000 - 50,000MOQ: 1 Set

-

Ceramsite Linear Vibration Sieve/seapratorUS$ 1,000 - 6,000MOQ: 1 Set

-

Gold Ore Wet Pan Mill/Pan Mill/Wet Grinder for Saudi Arabia MarketUS$ 1 - 10,000MOQ: 1 Set

-

3 Inch Mini Gold Mining Dredge With Lightest WeightUS$ 2,000 - 4,000MOQ: 1 Set

-

First-rate High Efficiency SZZ Series Self-centering Vibrating Screen With ISO 9001 CertificateUS$ 2,500 - 55,000MOQ: 1 Set

-

Vibrating Sieve for SaltUS$ 2,647 - 2,700MOQ: 1 Set

-

Belt Conveyor Magnetic SeparatorUS$ 7,500 - 10,000MOQ: 1 Set