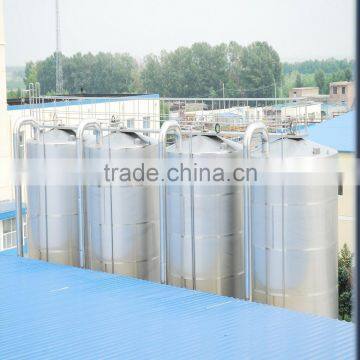

Stainless Steel Storage Tank, Heat Preservation Tank, Mixing Tank, Mixing Tank, Cold Hot Cylinder

The stainless steel insulation mixing tank provided by our company boasts merits of leakage proof, overall sealing, corrosion resistance and energy saving, etc. Without transmission torque, static seal replaces dynamic seal so as to tackle the inextricable leakage problem encountered by other shaft seals. With feed media and mixing components operating in aseptic sanitary environment, such tanks are the ideal replacement products applied to pharmaceutical, refined chemical, cosmetics and bio-engineering industries.

Various kinds of stainless steel storage tanks, insulation tanks, heating or cooling tanks, ingredient tanks, and ingredient dosing tanks.

Models of storage tanks include vertical type, horizontal type, open type, enclosed type, single-layer, double-layer, triple-layer, insulated type, heating or cooling type to meet your demand.

Stainless steel storage tanks, insulation tanks, heating or cooling tanks, ingredient tanks, and ingredient dosing tanks.

The equipment has rational design, advanced process technology with automatic control, complying with GMP standard. Tank body adopts vertical or horizontal type with single or double layer and jacketed with insulation material as requested by the client. The tank has its liner polished and cladding adopts mirror board or dull polish with insulation. At the top it is fitted with inlet opening, liquid return opening, sterilization opening, manhole and air vent. Client may choose different types or models according to their productivity. Clients may encounter such problems as whether to choose single or double layer tank, whether to choose stainless steel material or whether to adopt insulation or how thick plate sheet to adopt. Clients can also phone us to inform us of the more specific demands so that we can provide customized design and products against production requirements forwarded by the clients to make rational use of resources and offer best service to clients.

If the client has no special requirement on means of transportation, consignment shall be in shipment through Dalian port, China.

Projects installation in line with the requirements of the clients, turnkey projects of engineering design, installation, personnel training, installation and maintenance of piping and valves to equipment and technical support, etc.

Dasanyuan Coffee, Creamer & Dairy Machinery Co., Ltd., founding in 2000 and situated in China's Ice City –Harbin on the shore of the beautiful Songhua River, is a specialized company engaged in the design and equipment manufacture and installation in the fields of food, dairy and pharmaceutical projects. The company is a national high – tech industrial enterprise with the right for imports and exports.

The Company's projects concerning the dairy and food industries have covered over 100 enterprises in more than 20 provinces, municipalities and autonomous regions across the country. Our projects involve the design, equipment manufacturing and installation of the full- set production lines of milk powder, formula milk powder,

coffee powder, maltodextrin powder, soybean processing, soybean milk powder, creamer powder, liquid milk, yogurt drinks, soybean milk, and so on. In addition, the company also maintains long- term cooperation with

countries like Singapore, Malaysia, Thailand, the United States and Russia and other countries.

Technological innovation is the inexhaustible drive for the development of a company. We assume the mission of promoting the progress and development of domestic dairy technologies and equipment. Our technologies, processes and equipment in such areas as formulas powder processing, upper exhaust spray drying tower, multi- effect evaporator system, spray drying system for coffee powder, dextrin powder, and cream powder,

deep processing of milk products, such as, skim milk powder, cream, anhydrous cream, cheese prime and so on are widely used in the domestic and overseas dairy industry, which have won the favor of users both at home and abroad. The successful application of the independently developed “fully automatic- control

technology of the programmed formula powder production lines” which is the first of its kind in China has opened up a new chapter of the technological progress in the domestic dairy machinery industry.

Advanced management, an excellent corporate culture, high and new technological contents, superb product quality, good corporate reputation, and sound after- sales service constitute our foundation of survival.

We assume it our goal to wholeheartedly promote the development and technological progress of China's dairy industry.

We are expecting the development of China's dairy industry, and hoping to work with you hand in hand for our reciprocal future!

Send Inquiry to This Supplier

You May Also Like

-

Vertical Double Jacketed Stainless Steel Mixing Agitator TankNegotiableMOQ: 1

-

Gas TankUS$ 1200 - 2500MOQ: 1 Piece

-

Factory Directly Sale High Quality Milk Transportation Tank Milk Cooling Tank PriceUS$ 2,000 - 20,000MOQ: 1 Set

-

Steam Heating Double Jacket Agitator Mixing TankUS$ 2,500 - 3,000MOQ: 1 Unit

-

5m3 Factory Supply Liquid Nitrogen Storage Tank With Best QualityUS$ 15,880 - 17,960MOQ: 1 Set

-

Rotomold Auto Fuel Tank Water TankUS$ 20 - 200MOQ: 1 Set

-

Low Temperature Circulating Water Thermostatic Tank Temperature Test Laboratory Use Heating Cool Cycle WaterUS$ 700 - 758MOQ: 3 Sets

-

Prefabricated Large Diameter Water Diesel Fuel Oil Gas LPG Chemical Storage Tanks With Fabrication ServiceUS$ 2,000 - 3,500MOQ: 1

-

China Honglu Light Steel Structure Gas StationUS$ 1,300 - 1,400MOQ: 22 Tons

-

Electric Tank/slurry TankNegotiableMOQ: 1 Set