Introduction

Fruit wine or grape wine production line

The main technical consumption index

(1) Raw materials and water, electric, steam consumption

1.Alcohol water consumption 50t(Fresh water once)

2.Alcohol steam consumption 3.5~4.5t

3.Alcohol electric consumption 280KW.h

4.Alcohol grain consumption (corn) 3.1 tons, 66% of starch

(2) Accessory consumption

1,Amylase dosage 5-10 units/grams raw materials

2,Saccharifying enzyme dosage 150 units/grams raw materials

3,Active dry yeast dosage as raw material amount of 0.06-0.08%

4,Need a small amount of penicillin sterilization.

(3) Services

To undertake 1000 ~ 100000 tons/year full set of alcohol equipment design and manufacture,installation, debugging, workers technical training and turnkey projects.

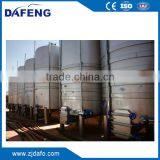

The configuration of tank

- The inner of the fermentation tank are adopted 304 stainless steel.

- Use polyurethane as insulating layer.

- Adopted the international standards of fermentation technology, diverse methods to control the temperature, the inner surface of the tank are mirror-polished.

- Completely meet the demanding of PLC and sterilize system.

- The cooling jacket can achieve all countries standard, supply miller, arch, corrugated plate and so on to meet all kinds of cooling technology of coolant and pressure.

A. Specifications

1. Wineproduction line

2. All production capacity

3. Factory and hotel are suitable

B. Main Description

1. Stainless steel 316

2. Liner thickness 2.5mm

3. 2mm thick water jacket

4. Automatic temperature control

5. Type: 2BBL; 3.5BBL;3HL;5HL;10HL;20HL;15BBL;30BBL;

6. Competitive price manufacture

7. Wine production line

8. All production capacity

9. Factory and hotel are suitable

C. Flow chart

Raw material→ Feeding → Selecting→ Cleaning→ Peduncle desteming and pulp crushing→ Juice extracting→ Seed separator→ Heating and cooling→ Juicing→ Fermentation→ Maturing→ Membrane filtration →Allocate →Filling →Seal-capping →Sterilization→ Cooling→ Code spurting→ Labeling→ Finished Product

Feeding conveyor→ Picking machine→ Scraper hoister→ Fruit cleaner→ Destemmer-crusher→ Juice extractor→ Seed separation machine→ Slurry storage tank→ Screw pump→ Tubular heater→ Centrifugal juicer→ Spiral mixer→ Pushing pump→ Juice storage tank→ Centrifugal pump→ Fermentation tank→ Centrifugal pump→ Storage tank→ Centrifugal pump→ Membrane filters→ Allocate tank→ Centrifugal pump→ Filling and capping machine→ Conveyor→ Tunnel freezer→ Code spurting machine→ Labeling machine→ Packing machine

1. Tank (Pressure Vessel) volume: 0.5-5000 cubic meters

2. Dimension: we could design diameter and height as per customers' request

3. Material: Stainless Steel (304 or 316L)

4. Tank shell thickness: 1.5-8mm

5. Pressure (MPa): Atmospheric pressure-Middle pressure (According to the Chinese Design standard)

6. Function: Storage or fermentation tank

7. Design temperature: -5-80 degree

8. Medium: Various drinks including wine, beer, fruit juice, and so on.

9. Tank surface: The original surface of the stainless steel plate (or polishing if required)

10. Operation plate form: We can design the platform if required.

11. Mixing: Top side or bottom mixing.

12. General accessories(If required): Manhole, CIP, respirator, sight glass, mixing

13. Manufacture standard: Chinese Pressure Vessel Design and Making Standard

14. Guarantees inner quality and safety, good looking appearance and function by introducing international advanced large-sized equipment of pulse plasma arcwelder and auto polishing machines and cooperating with international famous finished.

Fermenting system

Wine ferentation tank for hot sale

Processing line

Our company’s advantages over other companies:

Advanced Technology Co., Ltd Wenzhou is the a professional Stainless steel Mixing Equipment,Tank Pressure Vessels,Filters,Beer equipment and brewing technology supplier, who can professionally design, research and develop, and manufacture these equipment.

We can provide clients one-stop service from design, layout, to finished products. Its main business includes beer equipment, self brewing equipment, hotel beer equipment, draft beer dispenser, school laboratory equipment, etc. We mainly provide the capacity 500L/DF, 1000L/DF, 2000L/DF, 3000L/DF, 5000L/D,10000L/D,20000L/D etc.

Our staff of Sales and Technical Support is available to help you in selecting the right protection for your application as well as to provide you with Samples of our products for evaluation. At Advanced Tech., we are committed to providing the Highest level of customer service, Competitive pricing, Speedy delivery and a Comprehensive, cutting-edge product offering. Our ultimate goal is your satisfaction.

Our company’s quality certification:

We have got CE, PED, ISO9001 (2008) certificates. If necessary, we can offer electronic record’s certificates but the original document must be kept in the company.

Our company’s customer segmentation:

Our customer segmentation is mainly focused on the European,American developed countries such as the USA,Canada, Lati-America,the United Kingdom, Australia,

Saudi Arab and Asia etc. At present,we are looking for superior agents to create a brilliant future.

Choose us and get more benefits:

1. Deliver innovative products in the market at a faster pace;

2. Enhance the reliability of product’s quality;

3. Decrease the total cost of the product effectively;

4. Improve research personnel’s ability of creative design;

5. Gain more leading technologies about product development and increase the competitive advantage of products.

Pre-sale service:

1. Free of making offers, craft and technical guidance.

2. We can provide company’s qualification certification and the drawings.

3. We can also make customized products according to customer’s needs.

After-sale service:

1. We provide long-term after-sale service.

2. Meanwhile, you can call or e-mail to consult any relevant questions since we have a special line of after-sale service. Or you can communicate online and solve the problems.

Send Inquiry to This Supplier

You May Also Like

-

Automatic Spice Powder Grinding Machines Salt and Peeper Grinder Nut Grinder Machine for Food ProcessingUS$ 620 - 1060MOQ: 1 Set

-

Big Bags 1 Ton Jumbo Bag Powder Granule Packaging Machine FIBC Weighing Filling StationUS$ 1 - 48000MOQ: 1 Set

-

Stainless Steel 304 Beer Bottle Filling Equipment Electric 380V 50Hz 3 PhaseNegotiableMOQ: 1 Set

-

GNEYOND Protein Powder Filling and Seaming Line Milk Powder Tin Can Filling Sealing MachineNegotiableMOQ: 1 Set

-

Pyramid Tea Bag Packing Machine|Tea Sachet Packaging MachineNegotiableMOQ: 1 Set

-

China Small Beverage Bottle Wrapping Machine /juice Bottle Packing Machine/shrink Packing MachineUS$ 4,000 - 10,000MOQ: 1 Set

-

Chili Powder Processing Machine Seasoning Chili Powder Making Machine Mustard Powder Grinder for SaleUS$ 620 - 1060MOQ: 1 Set

-

Sweet Potato Powder Grinder Dried Black Beans Grinder Purple Sweet Potato Powder Grinder for SaleUS$ 620 - 1060MOQ: 1 Set

-

Weighing FIBC Bulk Jumbo 500kg 1000kg Ton Bulk Bag Automatic Filling Packaging Machine Big Bag Packing Machine Ton Bag SystemUS$ 1 - 48000MOQ: 1 Set

-

Precision Weighing Unit Big Bag Packaging Machine Automatic FIBC Packer 1000kg Bag Filling MachineUS$ 1 - 48000MOQ: 1 Set