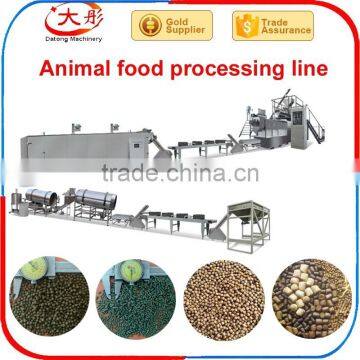

Good Operation Floating Fish Feed Pellet Making Machine

Good operation floating fish feed pellet making machine

1. Description

Fish feed machine uses foodstuff like meat powder, fishmeal, and beans etc. as raw materials to produce pet food and fish feed and bird feed with new shape, unique taste, rich nutrition and exquisite structure. The fish feed making machine are cooked and sterilized with high temperature and high pressure of the extruder, so it is easy to be absorbed and popular to the pet market.

2. Raw materials adopts corn flour, fish meal,soya as raw materials

3. Products: different shapes are made by adjusting the dies from extruder

4. Capacity: 100-150kg/h, 200-300kg/h, 300-500kg/h

5. Flow chart:---fish feed pellet equipment

Mixing system---Extrusion system----Drying system----Flavoring system--Packing system

6. Voltage in China: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries

7. Machines materials: All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

8. Technical Parameters

Feature of floating fish feed pellet making machine:

1). Our Pelletizers are used for making wood and feedstuff pellets.

2). We have be approved by European SGS.

3). Advanced and reliable technology.

4). High throughput capacity and high quality pellets.

5). Low-maintenance and service-friendly.

The raw material: sawdust, rice husk, cotton stalk, cottonseed skins, weeds, crop stalks and other plant wastes, especially low-bonding and unformed materials.

1.good quality

2.high efficiency

3.low labor

4.low price

Nitriding treatment(120 Hours)

Depth of Nitrided Layer: 0.5-0.8 mm

Hardness of Nitrided Layer: 950-1100Hv (HRC56°-65°)

Chrome Plating

Thickness of Hard Chrome Plating Layer: 0.05-0.10mm

Wear sleeve and screw sleeve are made of high wear-resistant alloy steel, to reduce abrasion and prolong service life.

Cutting System:

1.The blades is made of alloy steel,Very sharp.

2.It can cut the product easily.

3.Hardness material an used long time.

4.it can fix more cutter according require.

Conditioner Features:

A. preface which touches raw materials is stainless.

B. Adopt import sprayer, water needed enter mixer in fog.

C . Water quantity is adjusted according to requirements at any time, in order to meet different technology and different raw material.

D. We may put in water or steam, apply is wide.

1 Warranty time: one year, from the date which the product is qualified commissioning. Any damage except the wrong operation during warranty period is repaired freely. But the travel and hotel expenses should be count on buyer.

2 Commissioning services: the product's installation and commissioning at the demand side, our engineers will not leave there untill get your agreement.

3 Training services: our engineers will train your staff to operate it during the period of installation and commissioning, and they will not leave there until your staff can operate it properly and normally.

4 Maintenance services: any malfunction happened, once you enquiry us, we will reply you within 48 hours except the special reasons.

5 Lifelong services: we provide lifelong services for all the products we sold out, and supply the spare parts with discount price.

Jinan Datong Extrusion Machinery Co., Ltd is a professional food machinery manufacturer in Jinan city shandong province China.With our many years research and development extrusion technics has been widely used in more fields.

Our products consist of extrusion snack machine, twin screw food extruder, breakfast cereal and corn flakes machine, pet food machines and floating fish feed machinery,textured soya protein machine,modified starch machine, artificial rice making machine,bread crumb machine,single screw extruder,potato chips machine and biscuits machine, instant flour machine,flat bread machine,ect. We can also provide special design and product according to our clients` special requirements.

Now we have exported our machines to many countries, such as Malaysia, Indonesia. Pakistan, Sri Lanka, Brazil etc., and get good reputation from the clients. Some of them become our agents.

Welcome to visit Datong Extrusion Company!

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Send Inquiry to This Supplier

You May Also Like

-

New Design Fish Feed Mill Processing Equipment for Good SupplierUS$ 19,998 - 20,000MOQ: 1 Set

-

Brand New Fish Feed Mill Processing Extruder for Good SupplierUS$ 19,998 - 20,000MOQ: 1 Set

-

Plastic Fish Feed Mill Processing Machine for Good SupplierUS$ 19,998 - 20,000MOQ: 1 Set

-

Multifunctional Fish Feed Mill Processing Line With CEcertificateUS$ 19,998 - 20,000MOQ: 1 Set

-

Different Shape Fish Feed Mill Making Equipment With Great PriceUS$ 19,998 - 20,000MOQ: 1 Set

-

Gold Supplier Fish Feed Mill Making Extruder With FactoryUS$ 19,998 - 20,000MOQ: 1 Set

-

Professional Fish Feed Mill Making Machine for WholesalesUS$ 19,998 - 20,000MOQ: 1 Set

-

Brand New Fish Feed Mill Equipment for WholesalesUS$ 19,998 - 20,000MOQ: 1 Set

-

Factory Price Fish Feed Mill Extruder With Great PriceUS$ 19,998 - 20,000MOQ: 1 Set

-

Full Automatic Floating Fish Feed Pellet Production Equipment With CEcertificateUS$ 19,998 - 20,000MOQ: 1 Set