Limestone:

Limestone main component is calcium carbonate (CaCO3). Lime and limestone can be used as a lot of building materials, but also many important industrial raw materials. Limestone can be directly processed into stone and fired into the quicklime. Lime is divided into quicklime and slaked lime. The main components of quicklime is CaO, generally blocky, pure white, containing impurities is light gray or light yellow. Lime absorb moisture or water to become hydrated lime, lime, also known as slaked lime, its main ingredient is Ca (OH) 2. The deployment into slaked lime, lime paste, lime mortar, as coating materials and tile adhesives.

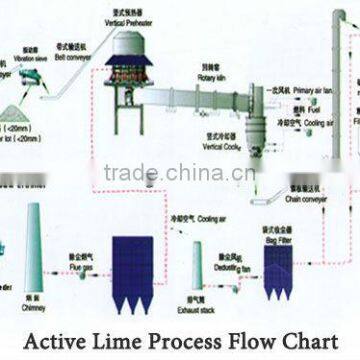

Active lime rotary kiln production line description:

Qualified limestone stored in silos, by the elevator Lift and transported into the preheater at the top of the silo. Preheater top hopper, the bottom two material position control feeding quantity, and then through the next feeding tube will be evenly distributed to the preheater limestone indoor.

Limestone preheater kiln is heated to 900 ° C by 1150 ° C flue gas and about 30% decomposition, by the hydraulic plunger push into the rotary kiln, rotary kiln sintered limestone and decomposed into CaO and CO2. Generated after decomposition of limestone, limestone into the cooler, the cooler was bubbled into the cold air cooled to 100 ° C at the discharge. The hot-swappable 600 ° C hot air into the kiln and gas combustion. Exhaust fan in blended with cold air entering through the baghouse, and then the exhaust fan into the chimney.

The lime is shipped into the lime products by the vibration feeder, chain conveyor, bucket conveyor, belt conveyor. Limekiln price can accord to customer requirements whether screening processes.

| design capability (t/d) | 150 | 300 | 600 |

| Product | Active lime | Active lime | Active lime |

| Preheater | Vertical preheater | Vertical preheater | Vertical preheater |

| Rotary kiln type(m) | Φ2.5×40 | Φ3.3×50 | Φ4×60 |

| Effective volume (m3) | 142 | 292 | 575 |

| Combustion temperature | ≤1250 | ≤1250 | ≤1250 |

| Cooling machine | Grate cooler | Grate cooler | Grate cooler |

| Fuel | coal gas Pulverized coal | coal gas Pulverized coal | coal gas Pulverized coal |

| heat rate (kJ/kg Cao) | 5000-5300 | 5000-5300 | 5100 |

Send Inquiry to This Supplier

You May Also Like

-

Hollow Brick and Paver Block Making Machines Maquina BloqueraNegotiableMOQ: 1 Set

-

Hot Sale Cement Interlocking Brick Making Machinery Automatic Hollow Concrete Block Making Machine China Brick Machines for Construction JobsUS$ 499 - 2256MOQ: 1 Set

-

Pioneer High Capacity AAC Block Production LineUS$ 300,000 - 1,500,000MOQ: 1 Set

-

Hand Press Block Making Machine QTJ4-50US$ 5,000 - 10,000MOQ: 1 Set

-

Precast Wall Panel Production Machine From Shandong YuruiUS$ 10,000 - 15,000MOQ: 1 Set

-

Hollow Brick Making Machine for SaleUS$ 1,000 - 30,000MOQ: 1 Set

-

Robotic Slab/Billet Marking SystemsNegotiableMOQ: 1 Set

-

China Concrete Brick Making Machine, Cement Brick Block Making MachineUS$ 1,000 - 8,000MOQ: 1 Set

-

732 Low Price for the Small Soil Brick Making Machine 0086-15136240765US$ 19,999 - 29,999MOQ: 1 Set

-

Construction Machine Mini Type Brick Making Machine QMR2-45NegotiableMOQ: 1 Piece