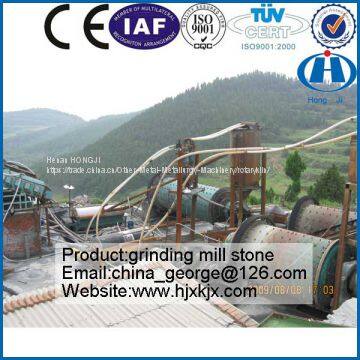

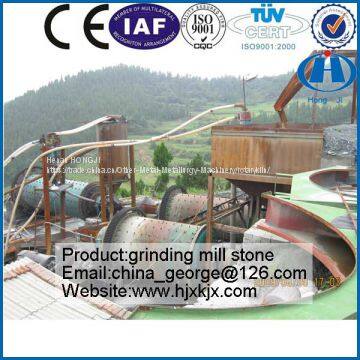

Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics.

It also can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Types of ball mill/ manganese ore grinding

Mill could be sorted as following:

As per the grinding media: ball mill, rod mill and AG Mill (without grinding media).

As per material discharging mode: wet grid mill, dry grid mill & overflow mill.

As per driving mode: side & central driving. The former is more popular now.

As per driving configuration:

a. Asynchronous motor driving: Asynchronous motor + Reducer + Pinion +Girth gear

b. Synchronous motor driving: Synchronous motor+ Air clutch+ Pinion +Girth gear

c. Asynchronous motor + reducer + diaphragm coupling

Structure of ball mill / manganese ore grinding

The machine is composed of feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control).

The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wearresistant liner, which has good wear-resistance.

For More Details Please do not hesitate to contact us via the following method

Email:china_george@126.com

Quick Lime, Cement Clinker Rotary Kiln

website:

Send Inquiry to This Supplier

You May Also Like

-

Mineral Processing Equipment Company in Cape TownEUR 1 - 1MOQ: 1 Ton

-

Equipments Used in Mineral ProcessingEUR 1 - 1MOQ: 1 Ton

-

Recycling of Media in Mineral Processing PlantEUR 1 - 1MOQ: 1 Ton

-

Tin Mineral Processing Equipment 4 to 8 Tones per HourEUR 1 - 1MOQ: 1 Ton

-

Copper Ore Processing PlantEUR 1 - 1MOQ: 1 Ton

-

Process Undergone by Gold OreEUR 1 - 1MOQ: 1 Ton

-

Gold Ore Mining ProcessEUR 1 - 1MOQ: 1 Ton

-

Highest Manganese Production in IndiaEUR 1 - 1MOQ: 1 Ton

-

Rock Phosphate Beneficiation Plant IndiaEUR 1 - 1MOQ: 1 Ton

-

Processes of Gold Separation and PurificationEUR 1 - 1MOQ: 1 Ton