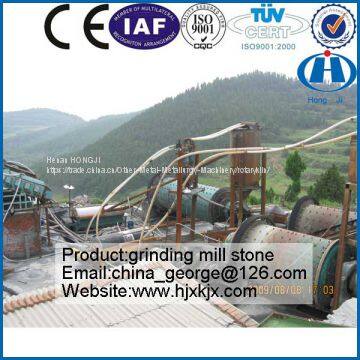

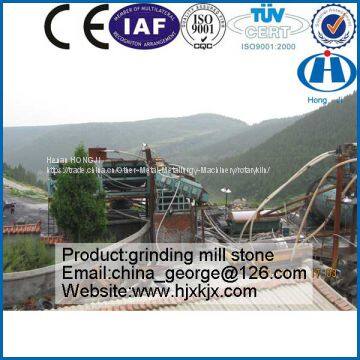

high-efficiency gold separation ball mill with ISO9001-2008

1. ISO9001-2008

2. good grinding quality

3. perfect service

Ball Mill

------------------------------------------------------------------------------------

A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, and ceramics.

------------------------------------------------------------------------------------

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

------------------------------------------------------------------------------------

Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls. An internal cascading effect reduces the material to a fine powder. Industrial ball mills can operate continuously, fed at one end and discharged at the other end. Large to medium-sized ball mills are mechanically rotated on their axis, but small ones normally consist of a cylindrical capped container that sits on two drive shafts (pulleys and belts are used to transmit rotary motion). A rock tumbler functions on the same principle. Ball mills are also used in pyrotechnics and the manufacture of black powder, but cannot be used in the preparation of some pyrotechnic mixtures such as flash powder because of their sensitivity to impact.

-------------------------------------------------------------------------------------

High-quality ball mills are potentially expensive and can grind mixture particles to as small as 5 nm, enormously increasing surface area and reaction rates. The grinding works on the principle of critical speed. The critical speed can be understood as that speed after which the steel balls (which are responsible for the grinding of particles) start rotating along the direction of the cylindrical device; thus causing no further grinding.

-------------------------------------------------------------------------------------

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls. An internal cascading effect reduces the material to a fine powder.

------------------------------------------------------------------------------------

Industrial ball mills can operate continuously, fed at one end and discharged at the other end. Large to medium-sized ball mills are mechanically rotated on their axis, but small ones normally consist of a cylindrical capped container that sits on two drive shafts (pulleys and belts are used to transmit rotary motion). A rock tumbler functions on the same principle. Ball mills are also used in pyrotechnics and the manufacture of black powder, but cannot be used in the preparation of some pyrotechnic mixtures such as flash powder because of their sensitivity to impact.

----------------------------------------------------------------------------------

Ball mills are used extensively in the Mechanical alloying process in which they are not only used for grinding but for cold welding as well, with the purpose of producing alloys from powders.

----------------------------------------------------------------------------------

Size

The smaller the media particles, the smaller the particle size of the final product. At the same time, the grinding media particles should be substantially larger than the largest pieces of material to be ground.

----------------------------------------------------------------------------------

Density

The media should be denser than the material being ground. It becomes a problem if the grinding media floats on top of the material to be ground.

----------------------------------------------------------------------------------

Hardness

The grinding media needs to be durable enough to grind the material, but where possible should not be so tough that it also wears down the tumbler at a fast pace.

For More Details Please do not hesitate to contact us via the following method

Email:china_george@126.com

Quick Lime, Cement Clinker Rotary Kiln

website:

Send Inquiry to This Supplier

You May Also Like

-

Iron Ore Pellet Plant Process DescriptionEUR 1 - 1MOQ: 1 Ton

-

Stlb20 Mining Centrifugal Gold Separator Gravity Gold Concentrator Shipped by SeaEUR 1 - 1MOQ: 1 Ton

-

Separation of Silicon From a Mixture of Gold and SiliconEUR 1 - 1MOQ: 1 Ton

-

How is Gold Separated From OreEUR 1 - 1MOQ: 1 Ton

-

Research in Equipment Used in Mineral Processing PdfEUR 1 - 1MOQ: 1 Ton

-

Modular Mineral Processing PlantEUR 1 - 1MOQ: 1 Ton

-

Iron Ore Beneficiation PlantEUR 1 - 1MOQ: 1 Ton

-

Gold Ore Processing From Usa ManufacturingEUR 1 - 1MOQ: 1 Ton

-

Which Chemical Useing Separation of Gold From MittiEUR 1 - 1MOQ: 1 Ton

-

Laboratory Mineral Processing EquipmentEUR 1 - 1MOQ: 1 Ton