Home > Products > Screen changer series > Screen Changer With Backflush Filtration Systems

Screen Changer With Backflush Filtration Systems

- China main port

- T/T L/C D/P D/A Money Gram

You May Like

-

Continuous Screen Changer

-

Plastic Extrusion Continual Screen Changer With Double Pillar Type Four Working Station

-

Double Working Position Hydraulic Screen Changer of Double-pillar Type

-

Automatic Extrusion Screen Changer

-

Screen Changer of Automatic Control Band Type Continual Screen Changer for Extrusion Line

-

One Pillar Single Working Station Screen Changer

Product Details

| Place of Origin | Zhejiang, China | Brand Name | TIANDEYI | |

| Shaping Mode | Other, Extrusion molding | Product Material | Steel | |

| Product | Other, Screen changer series |

Product Description

Name | Screen Changer with fully automatic backflush function (self-cleaning) |

1.When a pre-defined pollution degree is reached, the backflushing automatically starts. 2.Then the contaminations from the screen pack are led out of the machine via a spillway. The contaminated backflush mass leaves the machine by means of heated backflush outlet pipes which are installed at the screen changer housing. There the small quantity may be removed or collected. | |

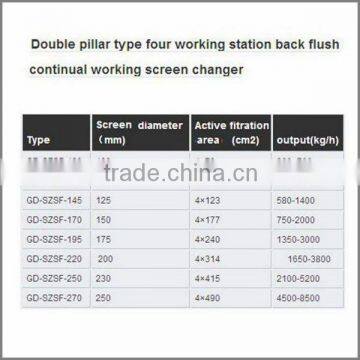

Categories include | Double pillar type four working station back flush continual working screen changer |

Application | Constant processes |

Characters | 1. The screens are used repeatedly because of the integrated self-cleaning (backflush). |

2. Fully automated backflush and venting procedure reduces the operator’s intervention to a minimum. | |

3. Up to 100 backflushes ensure a significant reduction in operating costs. | |

4. Processes with a high proportion of dirt (Recycling) | |

5. Processes to run automatically and without system downtime. | |

Heat Voltage | 220V or on customer’s request |

Heating | Electric, fluid or steam. |

Manufaturing process

1. Packaging Detail:

Outside package: Standard export wooden cases;

Inner package: Bubble wrap.

2. Delivery Detail:

Die length< 2000mm : within 30 days, 2000mm<Die length<3000mm, within 45 days.

The company wholeheartedly provide you with a full range of technical support and product services with a mature research and development, quality control, sales and service system.

1. Super quality:

1). Scientific Process and meticulous work from beginning to end insure that each set of die is perfect.

2). High quality steel, professional heat treatment, to prolong the maximum service life of dies.

3). Flow designing of dies are scientific and reasonable, reduce the thick edge effectively and make your cost down .

4). Using durable high quality parts: high quality stainless steel heating bar, heating uniformity, stability, high precision.

2. Competitive price, short delivery time

3. Customized products offered

1). Multiple adjustment methods of die lip opening for you to choose, convenient adjustment can save time, save labor costs to improve efficiency

2). Retain a full set of data and provide latingly technical services for you.

4. After-sale service

1). Timely response ;

2). Engineers available to service machinery overseas.

5. Profession with good reputation

Extrusion die series Including automatic control die , fast open lip die(fast gap die), coating die, various film dies,various sheet dies, multi-manifold coextrusion dies(Manifold die), single-layer or multi-layer grid hollow plate die (Hollow profile die), hollow special shape product die, and foam dies.

Ancillary equipments including co-extrusion feedblocks series, melt metering gear pump series, screen changer series, etc.

The products are widely used in the production of the plastic such as PR, BOPP, BOPET, PVDF, ETFE, PA, EVOH, EVA, TPU, ABS, PC, PMMA, PVC, PP, PE, CPP, CPE, PET, APET, PETG, PVB, PS, HIPS, LDPE, HDPE etc .

Our products are exported to Japan, the United States, Turkey, Mexico, Brazil, Bangladesh, Russia, India, Malaysia, Iran and other countries and regions and received high priase by our customers.

Please feel free to contact us, we will reply within 24h!

we want to know:

1. What's the products you want to produce?

2. What's the raw material?

3. What's the thickness of your product?

4. What's the product final width?

Thanks for your patience!

Contact Us

- Taizhou Huangyan Tiande Mold Machinery Co., Ltd.

- Contact nameJane Jiao Chat Now

- Phone0086-576-84362802

- AddressJinchuan Road, Huangyan Economic Development Area, Taizhou, Zhejiang, China

Product Categories

New Products

-

Single Piston Screen Changer With Enlarged Oval Shaped Screen Cavity

-

Single Pillar Single Working Station Screen Changer

-

Double Pillar Continual Working Plastic Filter

-

Double Pillar Double Working Station Screen Changer

-

Double Pillar Type Four Working Station Continual Screen Changer

-

Double Piston Double Working Station Screen Changer

-

Multi-layer Coextrusion Feedblock

-

Double Piston Plastic Screen Changer Series

-

Double Piston Screen Changer With Enlarged Oval Screen Shape for Continuous Operation

-

Plastic Screen Changer Series

-

Block Mould for Extrusion Feedblock for Multi-layer Composite Plastic Sheet \film

-

Exchange Screen Extruder Screen Changer for Sheet/film Line

-

Screen Changer of Double-pillar Hydraulic Plastic Extrusion Screen Changer for Extrusion Line

-

Plastic Extrusion Screen Changer With Double Pillar Double Working Station

-

Manual Control Extrusion Screen Changer

-

Plastic Screen Changer for Extrusion Line

-

Hydraulic Screen Changer With Double Working Position

-

Single-plate Hydraulic Screen Changer With Double Working Position

-

Plastic Extrusion Pack Screen Changer for Extrusion Sheet Line

-

Screen Changer of Single-plate Hydraulic Screen Changer for Extrusion Line

-

Automatic Control Band Type Continual Working Screen Changer

-

Automatical Rotary Filtration Systems

-

Single Plate Type Double-working Station Screen Changer

-

Screen Changer for Extrusion Plastic Machine

Popular Searches

- plastic mould

- pc abs

- pp pvc hdpe abs

- 3d design

- document

- agricultural plastic product

- plastic injection

- injection moulding

- injection mold

- plastic injection part

- appliance part

- injection mould

- extrusion die

- computer plastic mould

- home automation

- plastic injection mould

- mould design

- rubber mold

- molded product

- plastic injection molding product

- injection moulding product

- moulded product

- injection mould bumper

- injection molding

- household products part

- cycle component

- mould maker

- rubber flap

- bumper mold

- auto mudguard

Recommended Products

- Good Quality Eps Foam Package Mould Eps Foam Box Mould Machine

- High Quality Eps Foam Package Mould Eps Foam Box Mould Machine

- Good Quality Epp Foam Roller Mould Epp Foam Mould Roller Machine Tool

- Good Quality Epp Foam Box Mould Epp Foam Mould Machine Tool

- High Quality Epp Foam Moulding Box Epp Mould Machine Tool

- China Injection Tooling Maker for Plastic Mould Manufacture Factory

- High Quality Bainuo EPP Foaming Mould EPP Foam Machines for Package Box Automotive Parts

- High Quality Bainuo EPP Foaming Mould EPP Foam Machines for Package Box Autopart

- High Quality Bainuo EPS Foaming Mould EPS Foam Machines for Package Box

- Electronic Case Mold

- Electrical Appliances Plastic Cover Mold

- 2K Injection Molding Tooling

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mould > Plastic Mould

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Jane Jiao

Hi there! Welcome to my shop. Let me know if you have any questions.

Jane Jiao

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile