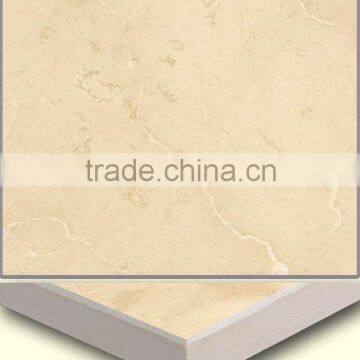

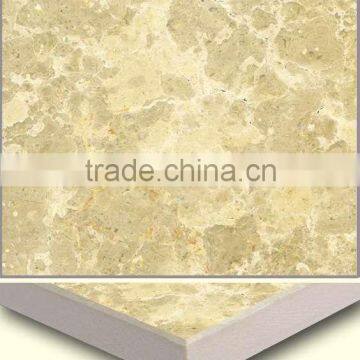

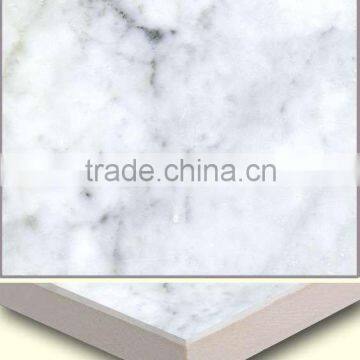

Excellent Quality PU Foam Marble Composite Tile/artificial Marble Baseboard Production Line.

Main Units

(1)Uncoiling unit

(2)Side block unit

(3)Preheating unit

(4)High pressure foaming unit

(5)Pur-metering unit

(6)Double belt conveyor unit

(7)Cooling unit

(8)Follow-up length cutting unit

Production Process

Production Application

Xiamen Oasis PU Machinery Co., Ltd located in a Chinese beautiful coast city, Xiamen, Fujian province, which has been engaged in designing, producing, developing, and trading of polyurethane (PU) machinery more than 20 years. The Oasis PU machinery Co., Ltd is dedicated in developing the polyurethane machinery technology and supplying our industry customer polyurethane mechanical equipment with high quality and competitive price. Our R&D (Research and Development) team always keeps on tracking the international advanced technology and our sales team supplies our suitable polyurethane machinery to our customer around the world. The best comparison between our products performance and the price of the same product is our biggest advantage over our competitors. And our superior service and excellent management makes our products enjoy a good reputation in the polyurethane processing machinery industry.

Q:What should I do if we aren’t able to operate the machine when we received it .

A: We dispatch technician to client’s site for installation and training for 15~30days.

Q:How could I get the spare parts on machine.

A:We will sent extra sets of spare and accessories. Non-artificial damaged spares will be sent free during one year warranty.

Q:How can I ensure that I get high-quality machine.

A: As a manufacturer, we have a strict supervision and control of every manufacturing step from raw materials purchasing ,brands choosing to parts processing, assembling and testing.

Q:Is there and insurance to guarantee I will get the right machine I pay for

A:We are an on-site check supplier from Alibaba. Trade Assurance provides quality protection. On-time shipment protection and 100% safety payment protection.

Pre-sale service:

Detailed pictures, operation video, technical diagram and quotation provided.

Before shipment:

Detailed photos are taken, operation video are taken with customer’s sample, spare parts and tools are listed.

After-sales service:

1 year warranty for spare parts, e-mail instruction/ video demonstration for technical problem, abroad site testing (costs on customer’s site).

Send Inquiry to This Supplier

You May Also Like

-

Plasterboard Manufacturing Machines/ Gypsum Board Production LineNegotiableMOQ: 1

-

SBS &APP Waterproof Membrane Production LineUS$ 96,000 - 583,000MOQ: 1 Set

-

China Pe200x300 Smallest Jaw CrusherNegotiableMOQ: 1 Set

-

Precast Concrete Wall Machine Manufacturing Sandwich Panel MachineUS$ 150,000 - 350,000MOQ: 1 Set

-

High Precision Aluminium and PVC Glass Batten Glazing Bead SawUS$ 600 - 1,100MOQ: 1 Set

-

Precast Concrete Hollow Core Wall Panel MachineryNegotiableMOQ: 1 Set

-

XQY3-10 Semi Automatic Cement Block Making MachineNegotiableMOQ: 1 Set

-

Quick Lime Production Plant for SaleUS$ 4,000,000 - 5,000,000MOQ: 1 Set

-

Building Material Precast Wall Panel MachineryUS$ 16,000 - 18,000MOQ: 1 Set

-

Good Quality TILE BACKER BOARD EXTRUSION LINEUS$ 1,000 - 50,000MOQ: 1 Set