Icf Insulated Panel Machine for Sell Xuelong ICF Machine

Xuelong Full-automatic ICF Molding Machine is one of the main products produced by Hebei Xuelong Machinery Manufacture Co.,Ltd.

The features of the EPS Shape Molding Machine:

1. The electric system adopts the most advanced PLC, touch screen, electromagnetic valve, encoder to ensure the reliable operation of Shape Molding Machine.

2. All parts and fittings of ICF Machine, such as the vacuum pump, the hydraulic pressure system, the valve body are customized and manufactured by prestigious manufacturers domestic and abroad, in order to accelerate the efficiency and reduce the failure rate of the of ICF Machine.

3. The programme of ICF Machine makes your work easy and produces high quality EPS products.You can operate the machines easily with the well-designed programs and the machines can produce high quality EPS products.

4. It adopts stainless steel plate for the support and back plate each contacting positions, which will reduce the wear and rust of the mold precision.

5. We can make the shape molding machine by requirements.

♦ Introduction of ICF panel construction :

Insulating concrete form or insulated concrete form (ICF) is a system of formwork for reinforced concrete usually made with a rigid thermal insulation that stays in place as a permanent interior and exterior substrate for walls, floors, and roofs. The forms are interlocking modular units that are dry-stacked (without mortar) and filled with concrete. The units lock together somewhat like Legobricks and create a form for the structural walls or floors of a building. ICF construction has become commonplace for both low rise commercial and high performance residential construction as more stringent energy efficiency and natural disaster resistant building codes are adopted.

♦ Introduction for XL-ICF1400 serious ICF panel machine :

XL-ICF 1400 serious ICF wall machine is reseach and designed by the best construction machanical engineers design team based advacned international ICF panel construction technology , and lead the trend of housing industrialization in China . Cooperate withTsinghua university and China Mining University and other scientific research institution .

The complete ICF panel wall machine / production line includes that :

(1). EPS pre-expander machine

(2). EPS beads aging silo and steam tubes .

(3). ICF panel molding machine

(4) ICF panel molds

(5). steam boiler and stam tank

(6). air compressor and air tank

♦ Main points For ICF panel production factory setting :

(1) workshop area need : 1500 - 2000 square meters .

(2) workers need for each production shift : 12 workers totally

(3) Each square meter of ICF panel production cost is 9 USD .

(4) EPS density scope : 15 - 35 kg/m3

♦ ICF panel machine / production line patent technologies certificates

♦ XL-ICF1400 serious ICF machine working condition :

♦ ICF panel ready products of XL-ICF 1400 panel machine :

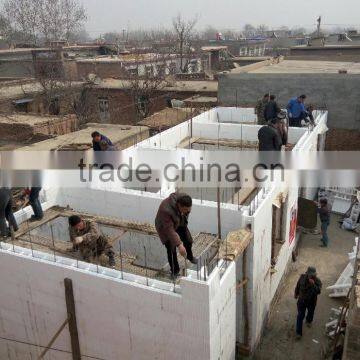

♦ ICF panel construction site photos:

♦ ICF panel machine / production line Packing before delivery

It accept stretch film packing for machine bodyand wooden packing for the ICF panel production line parts

l We supply factory layout design ; machine installation ; worker training

l Professional after sell and after-sell service team

Xuelong Advantages:

u Main parts after imported from famous factory in the world to control the machine with high quality.

u Machine design take the customer’s local environment and custom condition as consideration

u Machine main body with high quality steel and stainless steel and high quality painting to prevent rusting.

uXuelong company has more than 20 years experiences in eps machine fields that you can trust in China

u We are the famous brand in Hebei China.

1: Our factory Location

Our factory is located in Xinji city Hebei province, very close to Beijing.

2.How to get to our factory:

* You can directly fly to Shijiazhuang city, and we will pick up you from the air port.

* You can go to Beijing first, and then by fast train from Beijing to Shijiazhuang city, we will pick up you on the train station.

3: Why choose us?

Accomplishment

Xuelong company with cooperated with the first-class of famous University of Tsinghua. We have the strong technician team to serve our customer. We have successfully serve many domestic customers in the past.

High quality

The machine line main parts are imported from famous factory in the world. Such as Siemens ; Delixi ; OMRON and etc.

Competitive price

Our machine with competitive price because of local production cost. So we are the best partner for you to choose !

Innovation

Our team developed the new solutions for different customers of different requirements.

Skype: chem.china1

epsmachine(at)

QQ: 2536061877

Send Inquiry to This Supplier

You May Also Like

-

Plasterboard Manufacturing Machines/ Gypsum Board Production LineNegotiableMOQ: 1

-

SBS &APP Waterproof Membrane Production LineUS$ 96,000 - 583,000MOQ: 1 Set

-

China Pe200x300 Smallest Jaw CrusherNegotiableMOQ: 1 Set

-

Precast Concrete Wall Machine Manufacturing Sandwich Panel MachineUS$ 150,000 - 350,000MOQ: 1 Set

-

High Precision Aluminium and PVC Glass Batten Glazing Bead SawUS$ 600 - 1,100MOQ: 1 Set

-

Precast Concrete Hollow Core Wall Panel MachineryNegotiableMOQ: 1 Set

-

XQY3-10 Semi Automatic Cement Block Making MachineNegotiableMOQ: 1 Set

-

Quick Lime Production Plant for SaleUS$ 4,000,000 - 5,000,000MOQ: 1 Set

-

Building Material Precast Wall Panel MachineryUS$ 16,000 - 18,000MOQ: 1 Set

-

Good Quality TILE BACKER BOARD EXTRUSION LINEUS$ 1,000 - 50,000MOQ: 1 Set