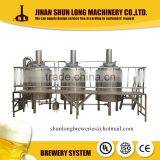

steam heating 2000l beer brewery equipment for sale

Jinan Shun Long Machinery Co., Ltd. is one professional manufacture and supplier of Beer plant small beer plant 50L-100L per batch in China.

We specialize in personally manufacturing small, medium and big sized beer plants.

Our breweries can be designed according to the specific wishes of our customers.

We also can offer you a wide variety of technical solutions.

Email or inquiry online. Contact us.

We are the professional beer brewing equipment manufacturer, so we have

- the sourse,

- the complete price,

- the high quality control.

Brewing is typically divided into 9 steps: milling, malting, mashing, lautering, boiling, fermenting, conditioning, filtering, and filling.

The mashing-lautering-boiling-whirlpool take place in the brewhosue, turn the malt into wort.

In order to provide the one-stop service, we could help you purchase the yeast, hops and other related raw materials for you.

Beer making equipment production power and Equipment covers an area of analysis:

dailyoutput | 100L | 200L | 300L | 500 | 1000L | 2000L |

unit type | SL-100 | SL-200 | SL-300 | SL-500 | SL-1000 | SL-2000 |

floorspace | 15square | 25square | 35square | 45square | 80square | 120square |

power | 12KW | 15KW | 20KW | 35KW | 35/15KW | 65/15KW |

Beer production period | 8-12 days | 8-12 days | 8-12 days | 8-12 days | 8-12 days | 8-12 days |

Standard feature:

*Stainless steel material 304/316

*Exterior thickness: 1.5~3.0mm

*Interior thickness:2.5mm~4.0mm

*Exterior: stainless steel/luxury red cooper

*Flange&dish head(single/double head)

*Temperature sensor

*Top manway

*Polyurethane 80~100mm

*Rotary cleaning ball, 360 degree no dead coner

* Hot water tank available&optional

2 vessel, 3 vessel and 4 vessel also availble, depend on your demands.

Process: mirro polishing, pure argon gas protecting welding, double face forming

Panel:Mirro/wire-drawing/2B optional

All pipelines and valves use food grade stainless steel 304 material

1.Inner are of international standards of quality 304 stainless steel material, high-pressure polyurethane foam insulation, the jacket in accordance with customer requirements, can be polished stainless steel, matt, carbon steel, the form of spraying.

2.The application of international standardized fermented beer production technology, a wide range of temperature control application technology, mirror polishing inside the tank, up to ≤0.8u≤0.6um≤0.2um polishing quality standards, fully meet the PLC automatic cleaning and disinfection of the controlled system requirements.

3.Fermentor cooling jacket at the same time meet the needs of the country the world’s technical standards, the provision of Maitreya paneles, arched passages spinulosa Watt Jacket channel heat exchangers and other methods to meet different cooling media and the pressure of the heat exchange technology needs.

Material: stainless steel AISI 304

thickness: 3mm

Inner surface treatment: cold-rolled plates , 2B surface treatment, welds grinded to Ra 0,8µm.

External surface treatment: cold-rolled plates grinded to SBCooling:

Cylinder: 3 cooling-sections

Conical bottom : 1 cooling-section

Working pressure in cooling-sections - 1,5 bar

Insulation: Polyurethane - thickness 150 mm, density 1,09 g/cm³:both cylinder and conical bottom

External-Jacket: Stainless steel plate - thickness 1,5 mm, both cylinder and conical bottom

Working pressure: 1,5 bar in cylindrical-part (filled-up tank, at 20°C)

1. Q: Do your products could be customized?

A: Yes, the beer equipment could be customized.

2. Q: Do you supply after-sales service?

A: Yes, we could supply after-sales service. We have 6 full-time engineers and other 4 part-time engineers available to go abroad to train installing and brewing.

3. Q: How long will the full set of equipment be guaranteed?

A: Three years warranty for main machine, one year warranty for the accessories.

4. Q: Are you trading company or manufacture?

A: We are a professional manufacture of beer equipment in this field.

5. Q: How is the proportion of your domestic market and foreign market?

A: 40% for domestic market, and 60% for foreign market.

6. Q: How long will the full set of equipment be shipped to us if we order it?

A: It will take 30-40 days to produce the full set of equipment.

7. Q: What should we do if there are problems during the process of using the equipment?

A: Firstly, we will communicate through email, skype or telephone, but if any accessory parts lead to problem, the accessory parts will be posted to you. If problems cannot be solved by all above mentioned method, our engineer will go abroad to solve for you.

8. Q: Do you also sell raw materials of brewing beer?

A: Yes, we do. We sell different kinds of raw materials including hops, yeast and malt.

1. Main tanks, vessels and machines will be packaged with painted steel frames.

2. All spare parts, accessories and fittings will be packaged with painted steel box.

3. All items wrapped with soft package for protection.

4. Standard shipping containers will be used for general purpose.

5. All equipments will be loaded into containers according to exact container layout drawings.

6. After loaded into containers, all equipments will be well fixed to the containers.

Varieties products and complete specification

Independent right of import and export

One of the biggest and most categories of fermentation equipment manufacturers in China

High quantity and competitive price

Our tenet:

modern and unic brewery equipment and breweries design, planning, drawing. Our quality engeniering will help you to locate your breweries in the best appropriative way for you.

We escort you during all the process. Our company assistents to you to save your money, your time and your nerves.

1.3 years warranty

2.Free installation and training

3.Design and maintenance for free

4.factory price,cusomized design,long-term after service

5.inner and outer of the tanks have been mirror polish

6.the material can be stainless steel with low price or red copper with nice-looking

7.the capacity can be 50L~30,000L

We can promise give you beer equipment with high quanlity and proper cost.

We can solve or give suggestions to all the related questions when using our Shunlong beer equipment as best as we can.

Send Inquiry to This Supplier

You May Also Like

-

Refrigerated Stainless Steel Conical Fermenter 1000L Large Brewing EquipmentNegotiableMOQ: 1 Set

-

Kitchen Appliances Espresso Coffee Bean Burr Grinding Mini Automatic Electric Coffee GrinderNegotiableMOQ: 1 Set

-

Heavy-Duty 4m High Basketball Court Fence With Anti-Climb DesignNegotiableMOQ: 1 Acre

-

2019 Shanghai Genyond Small Scale Commercial Tofu Production LineNegotiableMOQ: 1

-

Peanut Cutting Machine Almond Strip Cutting Machine Fast Cutting SpeedNegotiableMOQ: 1 Set

-

Factory Price Bean Bud Seedling Machine/Bean Sprout Growing Machine For SaleUS$ 1,500 - 7,999MOQ: 1 Set

-

Large Output Sprouts Cleaning Machine Vibration ShellerUS$ 1 - 2,500MOQ: 1 Set

-

Professional Manufacturer of Soybean Milk Process MachineUS$ 1,500 - 3,000MOQ: 1 Set

-

Green Bean Sprout Making Machine/machinery/makerNegotiableMOQ: 1 Set

-

Commercial Electric Peanuts Walnuts Sesame Oily Materials Mill Pulverizer GrinderUS$ 6,500 - 6,764MOQ: 1 Set