Gold Supplier Join-hedden Roll Forming Machine

Specifications

Welcome to review our roll forming machinewe are manufacture

Customers decide

Saving time and cost

complete service

Welcome to view 820 join-hedden roll forming machine

according to customers requirements ,costom roll forming machine

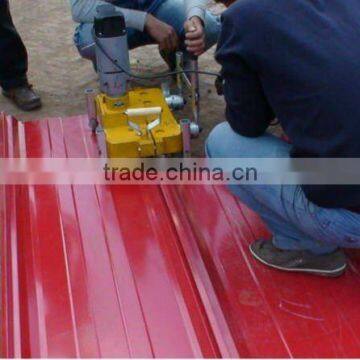

panel picture

1.Technical parameters:

| 1 | Main moter power | 4KW | |

| 2 | Hydraulic station power | 3KW | |

| 3 | Hydraulic oil pump | CB-E310 | |

| 4 | Sprocket | P-50.8 | |

| 5 | Roller station | 12-16 | |

| 6 | Yield strength | 32MPa | |

| 7 | Diameter of principal axis | 95MM | |

| 8 | Material of roller | 45#steel hard chrome plating | |

| 10 | Processing speed | 8-12m/min | |

| 11 | Thickness | 0.3-4mm | |

| 12 | Installation dimension about(L*W*H) | 10.5*1.4*1.2M | |

| 13 | Material of blade | Cr12 | |

| 14 | Total weight | 5-8T | |

| 15 | Equipment parts includes:5T decoiler, roll forming machine,hydraulic cutter,hydraulic station,electric controlling system,counter. | ||

2.Components

Components of line:

NO | Name | Unit | Qty |

1 | Manual decoiler | set | 1 |

2 | Main machine for roll forming | set | 1 |

3 | PLC Control system | set | 1 |

4 | Hydraulic system | set | 1 |

5 | Post cut | set | 1 |

6 | Stackinig | set | 1 |

•Noted:all the parameters can be changed as the customer's requirement,and different machine.

3.Sectional drawing

specialized manufacturer of roll forming machine,any requests just mail me.

Technical specification of every parts

1).decoiler: Optional

<1>. Manual un-coiler

|

processing

real photo of machine:

| Production Description | |

|

Equipment picture:

Material of main equipment:

Roller material: high grade NO.45 forged steel, plated hard chrome on the surface of roller with thickness 0.05mm.

Active shaft material: high grade NO.45 carbon wrought steel at diameter 72mm.

Cutting blade: Cr12 mould steel with quenched treatment.

They are widely used as the roof of garden like factory, hotel, exhibition center, villa, civil construction, etc.

Material of main equipment:

Features of the production line

1)Professional designing for manufactures roofing & walling

2)Automatically continually manufactures high quality product with PLC.

3)Easy operation : Directly input the data on the touchable screen.

4)Customers decide the profile of products.

5)Saving time and cost owing to high speed running with hydraulic system.

6)One year warranty.

EXELLENT QUALITY AND COMPETITIVE PRICE!

CHOOSE US , CHOOSE THE BEST!

Thank you for your time!

Send Inquiry to This Supplier

You May Also Like

-

pu Rolling Shutter Door Cold Roll Formng MachineUS$ 15,000 - 30,000MOQ: 1 Set

-

Professional in Stock Roof Tile Roll Forming MachineUS$ 7,000 - 9,000MOQ: 1 Set

-

QT8-130T Concrete Roof Tile Machine PricesUS$ 16,503 - 605,501MOQ: 1 Set

-

2014 Newest Roof Building Materials Making MachinesUS$ 1,000 - 50,000MOQ: 1 Set

-

Steel / Hot Galvanized Temporary Suspended Platform , ZLP500 Maintenance CradleNegotiableMOQ: 1 Set

-

Cummins Inline 5 Data Link Adapter Heavy Duty Truck Diagnostic ScannerNegotiableMOQ: 1 Set

-

2013 / 07 Mercedes Benz Star Diagnostic Tool For Benz Compact 4NegotiableMOQ: 1 Set

-

High Speed Perfessional and Efficient DMR900 Ground Polishing MachineNegotiableMOQ: 1 Set

-

Metal Stamping MachineUS$ 1 - 10MOQ: 500 Kilograms

-

Roofing Tile Galvanized Steel Sheet Corruged Panel Making MachineUS$ 3,000 - 3,000MOQ: 1 Set