QTJ6-15 Mult Function Fully Automatic Color Paver Machine Plant

QTJ6-15 Mult function Fully automatic color Paver machine plant

I. Description of Paver machine :

QT6-15 Paver machine adopts super-strong steel structure,special welding technology,numerous imported material and high-quality electric components, hydraulic parts,which ensure the stablility and reliability of the machine for loog term working under heavy load.

QT6-15 Paver machine adopts the computer to control the flowing rate and pressure of the hydraulic system,realizes the vertical synchrinous vibration,frequency-conversion and brake.The advanced mould-pressing vibrating method can make the concrete to be liquefied degassed within 2-3 seconds, which makes the product more compact and strong.

QTJ6-15 machine structure photo

II. Features of Paver machine :

1.Multi function: host displacement different molds can produce a variety of products. Such as the standard bricks, hollow brick, road brick, porous blocks ,etc..

2.Less electricity: in the process of operation, the motor is running for the moment, therefore, less electricity performance highlights.

3.Fast speed: the use of concave and convex mold landing fast, host molding and automatic material storage synchronously moving plate system makes the turnover plate instant replacement and forming a 26 block class output with habitat type vanguard.

4.High quality: special mold materials by professional staff Seiko made by the product geometry size, standard, the external quality and inner quality, unique design and mold shock combined external force caused by the product reaches the limit in the molding, so the density is very high, greatly improve the product the compressive and flexural strength.

5.Easy to operate: the machine molding pressure, the raw material used in water less at low temperatures can still production, equipment operation cycle is relatively prolonged years.

III. Main parts of the whole unit :

1.Mixer

Put all the materials into the mixer tank and mixed in it at the same time. It need one worker to operate the mixer.

2.Conveyor :

The mixed materials down from mixer conveyed to molding machine hopper for making blocks.

3.Brick machine :

The molding machine is the key of all production line. By pressing the mixed materials, it can make hollow bricks, porous bricks and standard bricks with different moulds.

It is controlled by PLC and Hydraulic station.

3.Block conveyor frame:

It will support the fresh blocks.

The fresh block/brick come out from mould convey to the block conveyor.

4.Trolley:

The trolley will transport the pallets with fresh blocks to the store yard for curing. Usually transport 3 pallets each time.

working photo

IV. Making blocks and pavers materials :

Making pavers and blocks materials

Pavers and blocks for reference .

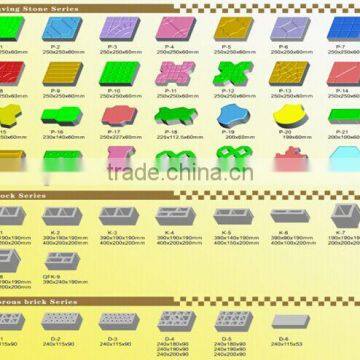

Making blocks ,pavers moulds photo

Color pavers photos

Concrete blocks photo

IV.Technical parameters of Fly ash concrete block making machine:

1.Concrete block making machine main Theoretical data: | |||

Dimension of host machine | 2850×2200×2850mm | Control style | PLC |

Forming style | Hydraulic | Vibration force | 45KN |

Vibrator style | table and mould vibrate togather | Raw material feeding style | 360 degree revole |

Forming hight | 40-250mm | Moulding period | 15-20S |

Moulding aera | 800×600mm | Size of pallet | 940×830×25mm |

Weight of host machine | 11.5T | Mixer style | JS500 |

General water Consumption | 8T/day | Voltage | 220/240/380/440V |

2.Simple block making machine line area needed: | |||

Workshop | 200m2 | ||

Office | 100m2 | ||

Total area | About 2000m2 | ||

Worker arrangement | |||

Operate | 1 Person | Material loader | 1 Person |

Drive forklift | 1 Person | Feeding pallets | 1 Person |

Maintain | 1 Person | Total | 5 Person |

| Products name | Specification | Pcs/pallets | Pcs/day | pcs/yar |

| Solid bricks : | 240*115*53mm | 32 | 57,600 | 1,728,000 |

| Hollow bricks : | 390*190*190mm | 6 | 11,520 | 34,556,000 |

| Porous bricks : | 240*115*90mm | 15 | 28,800 | 8,640,000 |

| Color Pavers: | Different size | 4pcs to 10pcs |

QTJ6-15 machine be sent photo

Zhengzhou YinHai Mining Machinery equipment Co., Ltd. is a hi-tech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices. Our products have been sold to 120 countries and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future. We hold "Pursuing the YinHaiTechnology and Quality" as our management concept all the time. Relying on absorbing world leading crushing and powder processing technology, advanced management and quality control system, as well as our full efforts, YINHAI has earned high reputation among our customers.

How about the quality of our machine?

Our machine manufactured strictly according to national and international standard.

We take a test on every machine before delivery

How about price of machine?

We can give the lowest price than market one.

We do quotation of machine as soon as possible for any custome.

Discount of machine can be given according to quantity.

Note: Above technical parameters are just for reference, if you want to get more detailed information or if you have any trouble in selecting the suitable machine, please contact us.

Send Inquiry to This Supplier

You May Also Like

-

Industrial Grade Brick Making Machine Designed for Manufacturing and Production FacilitiesNegotiableMOQ: 1 Set

-

Hollow Brick and Paver Block Making Machines Maquina BloqueraNegotiableMOQ: 1 Set

-

Pioneer High Capacity AAC Block Production LineUS$ 300,000 - 1,500,000MOQ: 1 Set

-

Hand Press Block Making Machine QTJ4-50US$ 5,000 - 10,000MOQ: 1 Set

-

Precast Wall Panel Production Machine From Shandong YuruiUS$ 10,000 - 15,000MOQ: 1 Set

-

Hollow Brick Making Machine for SaleUS$ 1,000 - 30,000MOQ: 1 Set

-

Robotic Slab/Billet Marking SystemsNegotiableMOQ: 1 Set

-

China Concrete Brick Making Machine, Cement Brick Block Making MachineUS$ 1,000 - 8,000MOQ: 1 Set

-

732 Low Price for the Small Soil Brick Making Machine 0086-15136240765US$ 19,999 - 29,999MOQ: 1 Set

-

Construction Machine Mini Type Brick Making Machine QMR2-45NegotiableMOQ: 1 Piece