CE Quality --Automatic Corrugated Paperboard Production Line

Machine Video on Youtube: https://youtu.be/R6XxsSIhNic

Product Application

1. The corrugated cardboard production line is used in base papers made into corrugated paperboard, adhesive, processing drying, definite form, slitting indentation, cross cutting into each kind of specification of corrugated carton box, and finally through the conveyor produce qualified products. High speed and high efficient flow operation.

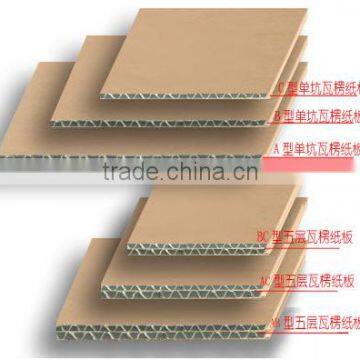

2. We can produce high quality, medium, ordinary 3 ply, 5 ply and 7ply corrugated production line. Widths from 1400-2200mm, flute profiles: A, B, C, E, production speed from 30-150 meters/min. We can supply a complete corrugators or individual parts to complement line

The production line can be designed and manufactured according to clients’ requirements, such as layers of cardboard, max. width, speed, etc.

The parts that the customers should buy or prepare by themselves:

1Steam heating system: suggest buying a 4000kg/hr steam boiler, pressure: 1.25Mpa, steam pipe.

2Air compressor, air-pipe, and the glue transport pipe.

3Electric power source, power wires connect from operation counter to power counter, and wire and pipe.

4Water source, water transport pipe, water bucket

5Water, electric, gas, ground work and civil work.

6The material paper and corn starch (potato), caustic soda, borax are used when the 1st testing of the production line.

7Lubricating oil, consistent lubricant, machine oil, hydraulic oil.

8Provide food, accommodation of the installer and offer workers when installing。

Hydrualic Mill Roll Stand

Hydraulic arm, clamping, expandable chuck, pneumatic control paper tention. Including kraft paper feeding trolley and guide rail.

SF-380 type Single Facer

Main corrugated roller is Φ380mm, 48CrMo high quality alloy steel, gimble driving, 22kw main motor, 15kw draught fan

Pre-heater

Φ1000,electromotion to large the craft paper’s preheating area, 0.37kw motor

Triplex preheater:

Φ1000,electromotion to large the craft paper’s preheating area, 0.37kw motor.

Double Gluing Machine

Glue rollers’ surfaces are annealed, inside hold processed, with dynamic balanced.

The surface is grinded and carved reticulated mottles, glue balance and costless

All the rollers surfaces are grinded and then chromed plated.

Conveying Bridge:

Electrical adjusting deflection, adsorptions tension.

Electric to correct the position of feeding( 2 sets),

correct parts are driven by .fast and accuracy to position, steady to move.

Double Facer Machine

600mm×16 pcs hot plate

upper-lower intensive pressure roller, could adjust pressure separately,hydraulic lifting and dropping of the pressure rollers, upper-lower intensive press roller, channel length:6m. high quality cotton belt(Shenyang Fuli Band)

55kw dynamo, Up Main Driving Roller:850mm, independent gear box, two cardan shaft driving.

NC Slitter Scorer Machine

5blades and 8scores, NC control, human-computer interface, Electrical adjusting deflection, store 99 orders

NC Cutoff Machine

Ac servo control, rotary blade, touch screen display, German KEB control system.Qingdao JASTU

Automatic Stacker

Variable frequency control transmission,speed of transmission and cardboard is same

Accurate count, vacuum adsorption type automatically change heap and order, accurately.

Glue supply by circulation

Steam pips and rotary joint system

Installation:

1, If buyer need installation the machinery, seller will provide two engineers help installation,

2, Two-way tickets, food and hotel charge pay by buyer, and one engineer salary is 80$/D.

3, Installation time: generally is 10days.

4, Training: free training 2-4 service people for our production line.

After-Sales Service

Free guarantee time: one year after installation

After-sale service: when the machinery happened problem,Engineers available to service machinery overseas. we also provide whole life machinery paid service.

Main Products of our Factory

91.8% Response Rate

All Spare parts we use are famous brand and was selected by customers themselves.

91.8% Response Rate

We have a 150000㎡ factory workshop to manufacture all machines.

91.8% Response Rate

Send Inquiry to This Supplier

You May Also Like

-

High Power Two Heads Packing Production Line Keg Washer Filler 0Ml - 1000MlNegotiableMOQ: 1 Unit

-

Aseptic Carton Filling Machine With Life-long Technical Support for Beverage DrinksNegotiableMOQ: 1 Set

-

Pizza Vending MachineNegotiableMOQ: 1 Piece

-

Automatic Multifunction Small Scale Coffee Packaging MachineUS$ 1000 - 10000MOQ: 1 Set

-

More Than 20 Years Factory Supply CE Certificate High Quality Aluminum Cans Compact MachineNegotiableMOQ: 1 Set

-

CE Automatic Bagging Machine 10-20kg/bagUS$ 4,000 - 10,000MOQ: 1 Set

-

2019 Canton Fair Best Selling Cookies / Sunflower Seeds / Sand Packing Machine PriceUS$ 12,500 - 45,000MOQ: 1 Set

-

Automatic Active Lime Manufacturing Flow EquipmentUS$ 100,000 - 1,000,000MOQ: 1 Set

-

China High Quality Laminated Cosmetic Tube Making MachineUS$ 10,000 - 20,000MOQ: 1 Piece

-

DP Series High Quality Automatic Cheetos Packing MachinesUS$ 5,000 - 32,000MOQ: 1 Piece