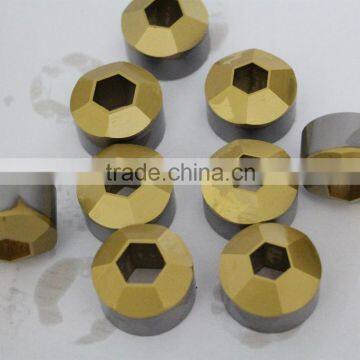

High Quality TiN Coating Trim Die Trimming Die

Custom Trim Die Trimming Die Blanking Die

Specifications:

OEM&ODM service

ISO9001 Certification

100% virgin steel

Features:

-We are professional manufacturer of various carbide Die and Tools .

-High Quality&Reasonable Price

About Us

Quality is our CULTUREL!

Henghui is a professional mold manufactuer.We specialize in design and produce series of Carbide Dies, Forging Dies,Punch Die,Punc Sets,Punch Pin and other Dies&Tools.Our products are exported to UK, European, Japan, Taiwan and South-east Asia etc.

PRODUCTION NOTE:

1. Select the tungsten steel materials and specifications size to make the screws or nuts mold correctly.

2.According to the difference of the forming difficulty,size,length of screws and nuts,rational design of the mold structure,multi-station and nut mold should be allocated on a reasonable basis the upsetting deformation and the number of molding.

3.The mold fine craftsmanship,accurate size,bore diameter to match the finish mirror requirements.

4.Interference voltage distribution margin,select the appropriate alloy taper size.

5.Shell steel sleeve must be rigid and good heated,and the hardness range should be between 42°c-48 °c after the vacuum heat treatment.

6.Keep the mold bore and the wire surface cleaning and smoothing, cold drawn wire must be nailed after ball annealing treatment.

7.We use diamond grinding wheel to mill the cycle and the end of tungsten.

8.The technicians adjusting the master must have good technical level.

We also have good after-sales service system to provide quality aftar-sales service for customers.

Send Inquiry to This Supplier

You May Also Like

-

Agriculture Using Plastic Shape Moulds Heart, Star, Square, Flower Shape Cucumber and Fruit MouldNegotiableMOQ: 500 Pieces

-

GYC Small 300-600kg/h Toilet Soap Making Machine From OilNegotiableMOQ: 1

-

OEM Customized Molded Enclosure Injection Plastic Molding For ElectronicsNegotiableMOQ: 1

-

Vanity TopNegotiableMOQ: 1

-

Brand New Waterproof Pvc Flooring With Great PriceUS$ 80 - 117MOQ: 1 Piece

-

Mould For ScrubberNegotiableMOQ: 1

-

Fully Automatic Cotton Swab Making Machine With Packing And Drying | Cotton Bud Maker Machine Wooden Cotton Swab Making MachineUS$ 23,500 - 23,500MOQ: 1 Set

-

Plastic Motor Part Mould, Laptop Plastic Parts Mould Such as Side Body Motorcycle, Fairying Covers for Motorcycle!US$ 0.1 - 2MOQ: 5000 Pieces

-

6.35mm Adjustable M2-M10 Carbon Steel Body Die Holder Wrench Set for Power ToolsUS$ 1 - 30MOQ: 640 Pieces

-

2016 Hot Selling Concrete Plastic Paving Mould for Interlock Tile MakingUS$ 1 - 5MOQ: 500 Pieces