Silicon Carbide Refractory Nozzle For Roller Kiln

Product Overviews of Sic Refractory Nozzle

1. Characteristics of SiC Nozzle

It is a kind of product with high strength, high hardness, high wear resistance,and good oxidation resistance, thermal shock resistance and other properties.

RSIC has more excellent long-term performance ( Compared with RSIC and N-SiC) the bending strength is more than

twice than RSIC,50% high than N-SiC.

2. Applications of Sic Nozzle

The various industrial furnaces, the desulphurization equipment, the large boiers and other machinery , and the ceramics, the machinery ,the metallurgy, the electronics,the chemicals, the petroteum , the iron and steel industry and other fields.

The series of beams are ideal kiln furnitures for sanitary ceramics, household porcelain, building

ceramics, electric porcelain, refractories, etc. They are specially used for load-bearing beams in shuttle kilns, tunnel kilns, roller hearth kilns and other industrial kilns.

3. Main Technology of SiC Nozzle

Item

| Unit

| Data | |||

RSiC

| SisiC

| N-SiC

| SSiC | ||

Bulk Density | (g/cm 3 ) | 2.60-2.72 | ≥3.02

| ≥2.75

| 2.95

|

Porosity | % | ≤17 | ≤0.1 | 10 | 0.5 |

Bending Strength (4-point) | MPa(at20℃) | ≥ 90 | ≥250 | 150 | 350 |

MPa(1200℃) | ≥100 | ≥280 | 170 | 450 | |

Thermal Expanssion | 10-6 k-1 | 4.8 | 4.8 | 4.6 | 4.2 |

Thermal conductivity | W/m.k | 23 | 45 | 25 | 90 |

Youngs Modulus | GPa(20℃) | 240 | 320 | 280 | 420 |

Working Temp. | ℃ | 1650 | 1350 | 1450 | 1700 |

4. Parameter of Sic Nozzle

Chemical Composition SIC >= | 90% | |

Physics property | Max. Service Temp. | 1400ºC |

Refractoriness >= | 39SK | |

| 2kg/cm2 Refractoriness under load T2 >= | 1790ºC

|

| Modulus of Rupturt at room temp >= | 500Kg/cm2 |

Modulus of Rupture at 1400ºC>= | 550Kg/cm2 | |

Compressive strenght >= | 1300Kg/cm2 | |

Thermal Expansion at 1000ºC | 0.42%-0.48% | |

| Apparent Porosity | ≤20% |

Bulk Density | (2.55-2.7)g/cm3 | |

Thermal Conductivity at 1000ºC | (13.5-14.5) Kcal/m.hr.ºC | |

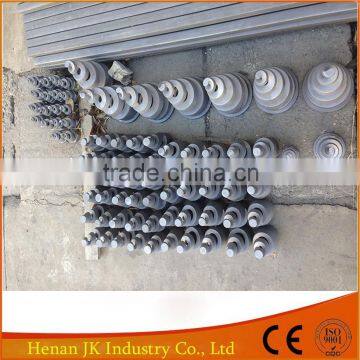

Product Shows of Sic Refractory Nozzle

Our All Typies Sic Products

Our Workshop

Packing and Shipping of Sic Spray Nozzle

(1) Packing: standard export packing , wooden case , cartoon case, It will be protect the products well.

(2) Shipping: Fast delivery, in general, it needs 5-15days after payment, and multiple transportation

methodsfor yourchoose, by sea/air/express/by the seller's shipping agaent are OK.

--By DHL/Fedex (Door to door, Home delivery service)

--By Air to your nearest Airport

--By Sea to your nearest Seaport

--By the sellers’ shipping agent

Send Inquiry to This Supplier

You May Also Like

-

Medical Devices & Equipments , Dental Equipments CNC Milling Services With Aluminum AlloyNegotiableMOQ: 1 Kilogram

-

Aluminum Metal Stamping Parts Performance Punched Parts For Electricity EquipmentNegotiableMOQ: 1 Kilogram

-

Silver Industrial Aluminium Sliding Door Profiles Aluminum Extrusion FabricationNegotiableMOQ: 1 Kilogram

-

Ceramic BallUS$ 0.86 - 3.65MOQ: 100 Kilograms

-

Lock-nuts Splicing Bolt Connector With Torque Wrench for Connecting RebarsNegotiableMOQ: 1 Kilogram

-

Custom Made Electric Motor Magnet NdFeB Ring Magnet For MicroMotor / MRIUS$ 0.01 - 2MOQ: 1 Kilogram

-

Passive Door Switch , Elevator Component / Parts , PB143NegotiableMOQ: 1 Kilogram

-

Brass / Aluminum CNC Turning Parts Services For Led Lamp NF UNI JPI 0.006mm ToloranceNegotiableMOQ: 1 Kilogram

-

Sell CenospheresNegotiableMOQ: 1 Kilogram

-

Modern Style Ceramic Flower VaseUS$ 1 - 2MOQ: 1000 Pieces