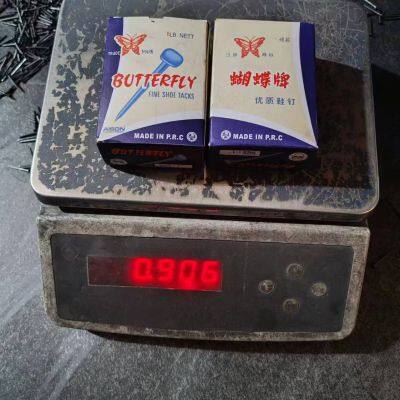

Butterfly Q195 Shoe Tacks Supplier - Precision Stamped for Shoemaking

Linyi Power Metal Products Co., Ltd, established in 2005, is a dedicated manufacturer specializing in high-quality metal components for the footwear industry. Our Butterfly Q195 Shoe Tacks are precision stamped to deliver exceptional reliability in shoemaking applications, ensuring secure fastening and enhanced durability. With a factory spanning 1,000-3,000 square meters and a team of 51-100 skilled employees, we produce consistent, cost-effective solutions that meet global standards. We proudly export to key markets like South America, Southeast Asia, and Africa, leveraging our expertise to support shoemakers worldwide. Trust our products to streamline your production process and reduce operational costs.

The Butterfly Q195 Shoe Tacks are engineered for precision and performance, making them ideal for attaching soles and other components in footwear manufacturing. Key features include:

- Material Excellence: Made from Q195 steel, these tacks offer superior strength and corrosion resistance, ensuring long-lasting hold in various environmental conditions.

- Precision Stamping: Our advanced stamping process guarantees uniform dimensions and sharp points, which minimizes slippage and improves assembly efficiency.

- Versatile Application: Designed specifically for shoemaking, they can be used in leather, synthetic, or hybrid footwear, providing a secure bond that withstands daily wear.

- Customizable Options: Sizes and packaging are adaptable to your needs, allowing for tailored solutions that fit specific production lines or machinery requirements.

Technical specifications highlight the product's robustness and adaptability. Below is a summary of key parameters:

| Attribute | Value |

|---|---|

| Material Type | Q195 Steel |

| Processing Method | Precision Stamped |

| Typical Length Range | 10-20 mm (customizable) |

| Diameter Options | 1-3 mm (available upon request) |

| Surface Finish | Smooth, non-reflective |

| Primary Use Case | Sole attachment in footwear |

These attributes translate into tangible benefits for your business. For instance, the precision stamping reduces waste by ensuring each tack fits perfectly, while the durable steel construction lowers replacement frequency, saving you money over time. Additionally, the customizable sizing allows integration with automated shoemaking equipment, boosting output by up to 20% in some setups. Clients report fewer defects and easier handling, leading to smoother production flows and higher customer satisfaction. By choosing our tacks, you invest in a component that enhances product longevity and supports sustainable manufacturing practices.

Backed by our annual export value of US$1-1.5 million and shipments via Qingdao Port, we guarantee timely delivery to regions like South Asia and the Middle East. Our experienced team ensures strict quality control from raw material sourcing to final packaging, making us a trusted partner for over 15 years. Don't compromise on your shoemaking essentials—reach out today for a quote or sample, and experience how our Butterfly Q195 Shoe Tacks can elevate your production efficiency and reliability.

Frequently Asked Questions (FAQ)

-

Q: What are Butterfly Q195 Shoe Tacks primarily used for?

A: They are designed for securing soles and other components in shoemaking, providing a strong, reliable fastening solution that enhances footwear durability. -

Q: Can I request custom sizes for these tacks?

A: Yes, sizes are customizable to match your specific machinery or product requirements; simply provide your specifications during ordering. -

Q: What material is used, and why is it suitable?

A: Made from Q195 steel, it offers excellent strength and corrosion resistance, ideal for withstanding the stresses of shoemaking and everyday use. -

Q: How does the precision stamping process benefit my production?

A: It ensures consistent dimensions and sharp points, reducing assembly errors and improving efficiency, which can lower overall manufacturing costs. -

Q: What packaging options are available?

A: Packaging is available upon request, with options like bulk boxes or custom containers to suit your logistics and storage needs. -

Q: Do you offer samples for testing?

A: Yes, samples can be provided upon request to evaluate quality and compatibility before placing larger orders. -

Q: What is the typical lead time for orders?

A: Lead times vary based on order size and customization but generally range from 2-4 weeks, with expedited options possible. -

Q: Which regions do you primarily export to?

A: We serve markets including South America, Southeast Asia, Africa, Mid East, and South Asia, with reliable shipping from Qingdao Port.

Send Inquiry to This Supplier

You May Also Like

-

Power Shoe Tacks Rust-resistant Fine Blue Dark Finish Multiple Sizes Available for Leather & Fabric Fixing Smooth Shank TypeNegotiableMOQ: 1 Ton

-

Three Star Brand Shoe Tacks - 1", 3/4", 1/2" Sizes Available With Anti-Rust CoatingNegotiableMOQ: 25 Tons

-

Cheap 1/2" Fine Blue Sofa Tacks - Heavy Duty for Leather and Fabric ApplicationsNegotiableMOQ: 25 Tons

-

Power Brand 3/4" Blue Upholstery Tacks - 500pcs Pack With Mill Test ReportNegotiableMOQ: 25 Tons

-

1/2" Sofa Tacks Nails - Rust Proof Finish for Long-Lasting Furniture FixingNegotiableMOQ: 25 Tons

-

High Quality 1" Shoe Tacks - 400g/box, 56boxes/carton Factory Direct From ChinaNegotiableMOQ: 25 Tons

-

Three Star Brand 1" Shoe Tacks Nails With Anti-Rust Coating for Leather CraftingNegotiableMOQ: 25 Tons

-

Power Brand 3/4" Blue Tacks for Upholstery - Made in China Factory DirectNegotiableMOQ: 25 Tons

-

Power Brand 3/4" Blue Tacks - 450g/box, 56boxes/carton Bulk Pack at Factory PriceNegotiableMOQ: 25 Tons

-

1/2" Fine Blue Sofa Tacks - Industrial Strength for Furniture AssemblyNegotiableMOQ: 25 Tons