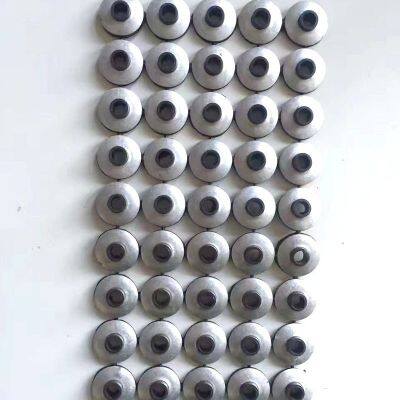

Stainless Steel IBR Nails for Metal Roofing - ASTM A153 Compliant

As a dedicated manufacturer since 2005, Linyi Power Metal Products Co., Ltd proudly introduces our Stainless Steel IBR Nails for Metal Roofing, engineered to meet ASTM A153 standards for reliable performance in demanding environments. With our factory spanning 1,000-3,000 square meters in Linyi, Shandong, and an annual export value of US$1 Million - US$1.5 Million, we deliver high-quality fasteners to key markets like South America, Southeast Asia, Africa, the Middle East, and South Asia, ensuring products are shipped efficiently from Qingdao Port. These nails are designed to provide exceptional corrosion resistance and durability, reducing long-term maintenance costs for roofing projects worldwide.

Our Stainless Steel IBR Nails feature a robust construction that excels in securing metal roofing sheets, offering superior grip and leak prevention. Key advantages include:

- Enhanced Longevity: Made from premium stainless steel, these nails resist rust and degradation even in humid or coastal conditions, extending the lifespan of roofing systems.

- Secure Fastening: The IBR (Industrial Building Roofing) design ensures a tight hold on metal sheets, minimizing wind uplift and improving structural stability for various building types.

- Compliance Assurance: ASTM A153 compliance guarantees consistent quality, with rigorous testing for fastener integrity, making them suitable for industrial and commercial applications.

- Ease of Installation: Engineered for straightforward driving with standard tools, these nails reduce labor time and costs, enhancing overall project efficiency.

Technical specifications highlight the adaptability and performance of our nails, with customizable options to suit diverse project needs. Below is a summary of common parameters:

| Parameter | Value |

|---|---|

| Material | Stainless Steel |

| Diameter Range | 3mm - 5mm (customizable) |

| Length Range | 20mm - 50mm (customizable) |

| Head Type | Flat or countersunk (optional) |

| Surface Finish | Smooth, corrosion-resistant |

| Compliance Standard | ASTM A153 |

Clients benefit from reduced replacement frequency and lower total ownership costs, as these nails withstand extreme temperatures and UV exposure without compromising integrity. For instance, in agricultural or warehouse roofing, they prevent leaks and structural failures, ensuring safety and compliance with building codes. Additionally, the corrosion-resistant properties make them ideal for regions with high rainfall or salt air, providing peace of mind for long-term investments.

Backed by over 18 years of manufacturing expertise and a skilled team of 51-100 employees, Linyi Power Metal Products Co., Ltd ensures every batch undergoes strict quality checks for consistency and reliability. Our extensive export network to markets like Africa and Southeast Asia, coupled with shipments from Qingdao Port, guarantees timely delivery and responsive support for global clients. Choose our ASTM A153 compliant nails for a dependable, cost-effective solution in metal roofing—contact us today for quotes or customized orders to meet your specific requirements.

Frequently Asked Questions:

-

Q: What does IBR mean in the context of these nails?

A: IBR stands for Industrial Building Roofing, referring to a specialized design that provides secure fastening for corrugated metal roofing sheets, commonly used in commercial and industrial structures. -

Q: Are these nails suitable for use in high-moisture environments like coastal areas?

A: Yes, the stainless steel material offers excellent corrosion resistance, making them ideal for coastal or humid regions where rust is a concern. -

Q: What sizes and configurations are available for these roofing nails?

A: Sizes such as diameter (3mm-5mm) and length (20mm-50mm) are customizable upon request, with options for different head types to match installation tools. -

Q: How does ASTM A153 compliance benefit my roofing project?

A: Compliance ensures the nails meet standardized requirements for durability and performance, reducing risks of fastener failure and enhancing overall roof longevity. -

Q: Can I order small quantities or samples before a bulk purchase?

A: Yes, samples are available upon request for quality evaluation, and we accommodate various order sizes to fit your project scale. -

Q: What is the typical lead time for delivery to international markets?

A: Lead times vary but average 20-30 days for standard orders, with shipments handled efficiently from Qingdao Port to destinations like South America or Africa. -

Q: Do these nails require special tools for installation?

A: No, they can be installed using common roofing nail guns or hammers, ensuring straightforward application without additional equipment costs. -

Q: How do you ensure product quality during manufacturing?

A: Our factory employs rigorous quality control processes, including material inspections and batch testing, to maintain high standards across all production runs.

Send Inquiry to This Supplier

You May Also Like

-

IBR Roofing Nails Supplier With 10-Year Rust Resistance WarrantyNegotiableMOQ: 5 Metric Tons

-

Electro-Galvanized IBR Nails Manufacturer - 3.0mm Shank for Heavy-Duty RoofingNegotiableMOQ: 5 Metric Tons

-

Hot-Dipped IBR Roofing Nails - 50mm Length With Weatherproof CoatingNegotiableMOQ: 5 Metric Tons

-

Galvanized IBR Nails for Roofing Sheets - 2.5mm Shank DiameterNegotiableMOQ: 5 Metric Tons

-

Specialized IBR Nails for Agricultural Building Roofing SystemsNegotiableMOQ: 5 Metric Tons

-

Concrete Nails With Warranty - Bulk Pack for ContractorsNegotiableMOQ: 5 Metric Tons

-

Steel Concrete Nails for Concrete Form Ties - 4.0mm DiameterNegotiableMOQ: 5 Metric Tons

-

Galvanized Steel Concrete Nails for Construction - 2.5mm to 4.5mm DiameterNegotiableMOQ: 5 Metric Tons

-

Concrete Nails for Heavy-Duty Fastening - 3.2mm Thick ShaftNegotiableMOQ: 5 Metric Tons

-

Concrete Nails for Formwork and Scaffolding - 75mm LengthNegotiableMOQ: 5 Metric Tons