Reinforced Container Liner Bag With 4-Ply Construction for Abrasive Materials

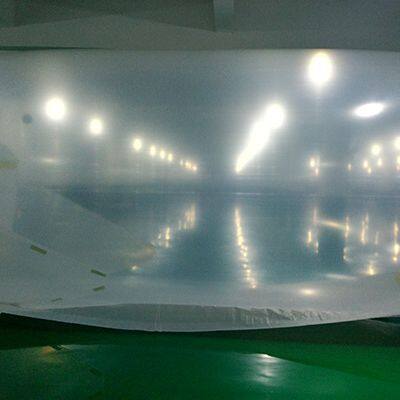

As a specialized manufacturer based in Xuzhou, Jiangsu, China, Xuzhou Guozi Intelligent Technology Co., Ltd. designs and produces industrial packaging solutions engineered for demanding logistics. Our Reinforced Container Liner Bag with 4-Ply Construction stands as a critical solution for businesses handling abrasive bulk materials. Engineered specifically to withstand the punishing effects of sharp, heavy, or rough cargo during transport and unloading, this liner bag significantly reduces container damage, prevents costly material loss, and enhances operational efficiency. By choosing our robust liner, you invest in reliable cargo integrity and streamlined logistics.

Core Design & Technical Specifications:

This liner bag is defined by its heavy-duty 4-ply construction, utilizing multiple layers of specially formulated polypropylene fabric. This multi-layered approach is fundamental to its exceptional performance:

- Superior Abrasion Resistance: The outer layers are treated and woven to endure constant friction and scraping from sharp-edged materials like ores, minerals, recycled metals, or gravel without tearing.

- Enhanced Puncture & Tear Strength: The inner layers provide critical reinforcement, distributing impact forces and resisting punctures caused by heavy or jagged loads, preventing catastrophic failure.

- Optimized Load Distribution: The 4-ply structure ensures the weight of the abrasive material is evenly distributed across the bag's surface, minimizing stress points and potential rupture.

- Improved Seam Integrity: Seams are double-stitched or welded using high-tensile thread/technology, specifically reinforced to handle the stress exerted by dense, shifting abrasive cargo.

Key Technical Parameters (Standard):

| Parameter | Value | Notes |

| Compatible Container | 20ft, 40ft | Precise fit minimizes shifting |

| Material Thickness (approx.) | 150-220 GSM per ply | Total thickness ~600-880 GSM |

| Top Filling Design | Spout or Open Top | Customizable |

| Bottom Discharge | Duffel/Tie-off, Spout | Facilitates clean unloading |

| Lifting Loops | Integrated | For safe positioning/removal |

Tangible Benefits for Your Operation:

- Dramatically Reduced Container Wear & Maintenance: Protects the container floor and walls from direct contact with abrasive materials, extending the container's service life and lowering repair costs.

- Minimized Product Loss & Contamination: Prevents leakage and spillage of valuable or hazardous abrasive materials, ensuring more product reaches its destination and reducing clean-up expenses. Keeps cargo clean.

- Increased Loading/Unloading Speed & Safety: Designed for compatibility with standard loading equipment (e.g., conveyor spouts) and easy discharge methods, improving turnaround times and reducing manual handling risks.

- Cost-Effective Reusability (Potential): Depending on material abrasiveness and handling procedures, these robust liners can often be reused multiple times for suitable products, offering long-term savings.

- Versatile Material Handling: Ideal for transporting a wide range of challenging dry bulk goods including metal scraps, minerals (iron ore, coal, bauxite), aggregates, sand, recycled glass, and certain industrial wastes.

Trust & Commitment from Xuzhou Guozi:

Manufactured at our facility in Xuzhou, Jiangsu, a key industrial hub in China, our Reinforced Container Liner Bags are produced under stringent quality control processes. We leverage our expertise in intelligent packaging technology to deliver solutions that meet the rigorous demands of global abrasive material transport. Our commitment is to provide durable, reliable, and cost-effective liner bags that protect your investment in both cargo and shipping containers. Partner with us for a liner solution engineered to handle the toughest loads.

Frequently Asked Questions (FAQ):

Q1: How many times can I typically reuse this 4-ply liner for abrasive materials?

A: Reusability depends heavily on the specific abrasiveness of the material, loading/unloading methods, and handling procedures. While designed for durability, highly sharp materials may limit reuse. We recommend inspecting the liner carefully after each use. Some customers achieve 3-5 uses for moderately abrasive cargo.

Q2: Are these liners suitable for very fine, dusty abrasive materials?

A: Yes. The multi-layer polypropylene construction provides an effective barrier against fine dust particles, preventing leakage and contamination. For extremely fine powders, we can discuss options with tighter weaves or optional coatings upon request.

Q3: Can I get liners for non-standard container sizes?

A: Absolutely. Custom sizing is a core service we offer. Provide us with the exact internal dimensions of your container or transport unit, and we can manufacture liners for a precise fit.

Q4: What is the lead time for standard vs. custom orders?

A: Standard sizes (20ft/40ft) typically have shorter lead times, often within 2-3 weeks. Custom sizes, materials, or features may require 4-6 weeks depending on complexity and order volume. Contact us for a precise quote based on your needs.

Q5: How do you ensure the seams can handle heavy, abrasive loads?

A: Seams are a critical focus. We use reinforced stitching techniques with high-tenacity thread and/or specialized welding (like hot wedge welding) specifically designed to create strong, continuous seals that resist the stress and abrasion encountered during filling, transport, and discharge of dense materials.

Q6: What is the best way to load abrasive material into these liners?

A: Controlled loading is recommended. Using a conveyor spout centered within the filling opening helps distribute material evenly and minimizes direct impact on specific areas of the liner. Avoid dropping material from excessive heights directly onto the liner surface.

Q7: Do you offer different bottom discharge options?

A: Yes. Common options include a robust duffel-style bottom (folded and tied/sealed) or a discharge spout. The choice depends on your unloading equipment and process. We can advise on the most suitable option for abrasive materials.

Q8: How are the liners secured inside the container?

A: Our liners feature integrated heavy-duty lifting and securing loops. These loops are designed to be attached to the container's lashing points or internal structures using ropes or straps, holding the liner securely in place during transit and preventing collapse during discharge.

Send Inquiry to This Supplier

You May Also Like

-

20FT 40FT Container Liner Bag Dry Bulk PE Liner for Cocoa BeansNegotiableMOQ: 1000 Pieces

-

20FT Container Bulk Liner Bag With Zipper for Soybean LogisticsNegotiableMOQ: 1000 Pieces

-

Breathable Container Liner for Agricultural Product StorageNegotiableMOQ: 1000 Pieces

-

Reinforced Container Liner for Heavy-Duty Cargo TransportNegotiableMOQ: 1000 Pieces

-

Container Liner With Fire-Retardant Properties for Hazardous GoodsNegotiableMOQ: 1000 Pieces

-

Container Liners for Dry Bulk or Flowing Goods Logistics 20FT 40FTNegotiableMOQ: 1000 Pieces

-

Waterproof Dry Bulk Liner for 20 FT Container to Transport Powder CargoNegotiableMOQ: 1000 Pieces

-

Container Liner With Quick-Installation System for Efficient LoadingNegotiableMOQ: 1000 Pieces

-

Waterproof Container Liner for Marine and Logistics UseNegotiableMOQ: 1000 Pieces

-

Container Liner for Food-Grade Cargo With Mill Test ReportNegotiableMOQ: 1000 Pieces