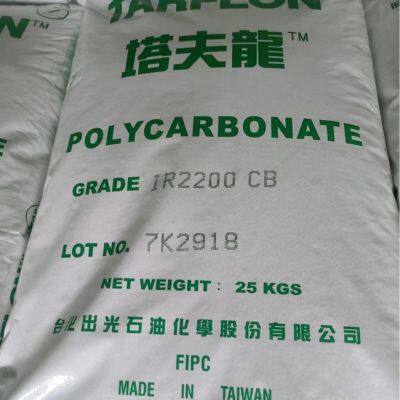

IR2200 Polycarbonate Plastic Raw Material - Excellent Impact Strength & UV Stability

Suzhou Yifuhui New Material Co., Ltd., a trusted trading company established in 2020, specializes in delivering premium polymer solutions to global markets. Our IR2200 Polycarbonate Plastic Raw Material exemplifies our commitment to quality, offering exceptional impact resistance and UV stability for demanding industrial applications. With an annual export value of US$10-50 million and shipments from major ports like Shanghai, Ningbo, and Qingdao, we serve diverse markets including North America, Europe, and Southeast Asia.

Core Advantages:

- Superior Durability: Engineered to withstand high-impact stresses without cracking, ideal for safety-critical components.

- Long-Term Weather Resistance: UV stabilizers prevent yellowing and degradation in outdoor environments.

- Design Flexibility: Suitable for complex geometries via injection molding or extrusion processes.

Technical Specifications:

| Property | Value | Test Standard |

|---|---|---|

| Melt Flow Index | 10 g/10min (300°C/1.2kg) | ISO 1133 |

| Tensile Strength | ≥ 60 MPa | ISO 527 |

| Notched Impact Strength | ≥ 80 kJ/m² | ISO 180 |

Key Applications:

- Automotive: Lightweight lens covers, dashboard components

- Electronics: Smartphone cases, power tool housings

- Construction: Skylight panels, noise barriers

Backed by our extensive reach across 14 global markets including Oceania and Africa, we ensure reliable supply chain support. Our material’s consistent performance reduces production downtime and extends product lifespan, delivering tangible cost savings. Custom formulations (e.g., flame retardant grades) are available upon request to meet specific project needs.

FAQ:

-

Q: Can IR2200 be used for food-contact applications?

A: Standard grades are not food-certified. Food-safe options require customization. -

Q: What is the typical lead time for orders?

A: 15-25 days depending on destination port and quantity. -

Q: Does it require drying before processing?

A: Yes, recommended drying at 120°C for 3-4 hours. -

Q: Is coloring available?

A: Natural pellets can be custom-colored with masterbatches. -

Q: Minimum order quantity?

A: 500 kg for standard grades; contact for custom solutions. -

Q: How is UV stability achieved?

A: Through co-polymerization with UV-absorbing monomers.

Choose IR2200 for projects demanding resilience and longevity. Contact us today for technical data sheets or bulk quotations – let our expertise in serving markets from Western Europe to South Asia enhance your product performance.

Send Inquiry to This Supplier

You May Also Like

-

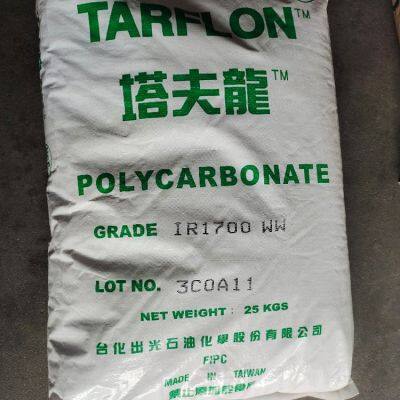

High-Temperature Resistant TARFLON® IR2200 PC Material for Automotive Lighting SystemsNegotiableMOQ: 25 Kilograms

-

Infrared Transparent TARFLON® IR2200 Polycarbonate for Laser Welding Applications in ElectronicsNegotiableMOQ: 25 Kilograms

-

IR2200 PC Grade: High Clarity Infrared Material for Medical and Automotive Laser DevicesNegotiableMOQ: 25 Kilograms

-

TARFLON Polycarbonate Resin for Automotive Parts Requiring High Heat ResistanceNegotiableMOQ: 25 Kilograms

-

UL94 V-0 Rated TARFLON PC Resin Granules for Electrical Components ManufacturingNegotiableMOQ: 25 Kilograms

-

High-Quality TARFLON Polycarbonate Resin Pellets for Engineering Plastics ProductionNegotiableMOQ: 25 Kilograms

-

TARFLON Polycarbonate Granules With Low Warpage for Precision Electronic HousingsNegotiableMOQ: 25 Kilograms

-

TARFLON Polycarbonate Pellets Compatible With ABS for Enhanced Material PropertiesNegotiableMOQ: 25 Kilograms

-

Flame Retardant TARFLON PC Resin Pellets With Excellent Heat Resistance & Dimensional StabilityNegotiableMOQ: 25 Kilograms

-

UV-Stabilized TARFLON Polycarbonate Pellets for Outdoor Equipment ManufacturingNegotiableMOQ: 25 Kilograms