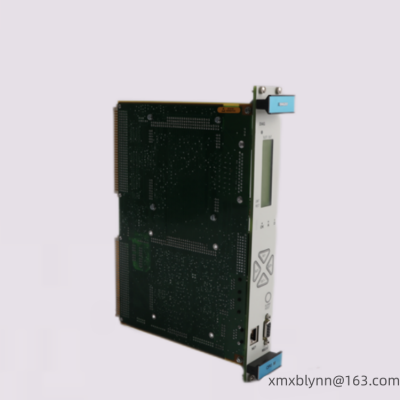

VIBRO-METER 200-595-045-114 CPUM Rated Voltage

200-595-045-114 is the core CPUM (CPU Modular) rack controller and communication gateway module of the VM600 mechanical protection and condition monitoring system under Meggitt Vibro-Meter. It works in conjunction with the matching IOCN card, serving as the "system brain" and data interaction hub of the entire rack. It manages monitoring cards, processes key data such as vibration, displacement, and speed, and enables communication with the upper-level system. It is a core component for online monitoring and safety protection of large rotating machinery.

Email: xmxblynn@163.com

Phone: +86 18059884797

Make/Model:VIBRO-METER

Country of Origin: made in the USA

H.S Code: 85389000.00

Gross Weight & Net Weight.

Port of shipment:XIAMEN

Delivery period: 1-2 weeks

Validity period: 30 days

Core Product Functions

1. Centralized Rack Control and Unified Management

Achieves **one-time configuration management** for all protection/monitoring cards such as MPC4 and AMC8 within the VM600 rack. Connects to the VM600 MPSx software via Ethernet/RS-232, enabling one-click parameter distribution, calibration, and status synchronization for the entire rack, significantly simplifying system deployment and commissioning processes.

Supports hot-swapping of monitoring cards. The system automatically identifies new cards and loads configurations during insertion/removal, ensuring uninterrupted system monitoring and meeting the needs of on-site maintenance without downtime.

Built-in rack access control and security mechanisms prevent unauthorized modification of monitoring thresholds and protection logic, ensuring system operational security.

Provides a universal alarm reset (AR) function, allowing one-click reset of the alarm status of all protection cards within the rack, adapting to emergency maintenance operations in the field.

2. High-Precision Data Acquisition and Intelligent Processing: Real-time acquisition of dynamic/static signals such as shaft vibration, shaft displacement, differential expansion, rotational speed, and bearing temperature from front-end eddy current, acceleration, and velocity sensors. The built-in processor and FPGA perform digital filtering, high-resolution FFT analysis, and order tracking to accurately extract equipment fault characteristics (such as imbalance, misalignment, and bearing wear).

Features a high sampling rate and wide dynamic range, completely reproducing weak vibration signals to ensure monitoring data accuracy and provide a reliable basis for equipment condition assessment.

Records complete system and measurement event logs, including alarm triggers, parameter modifications, module status changes, communication anomalies, and other comprehensive information. This log can be exported via MPSx software, supporting equipment fault tracing and maintenance optimization.

3. Multi-Protocol Communication and System Integration: Equipped with a high-speed Ethernet interface, supporting mainstream industrial bus protocols such as Modbus TCP and PROFINET, it can seamlessly interface with DCS, PLC, SCADA, and MPSx host computers to uniformly forward monitoring data, alarm signals, and control commands.

Equipped with RS-232/RS-485 serial interfaces, supporting the Modbus RTU protocol, it is compatible with legacy industrial systems and can build multi-point RS-485 cascaded networks to meet the communication needs of multi-rack distributed monitoring.

As a communication gateway between the VM600 system and third-party devices, it establishes a data link between the field monitoring layer and the plant management layer, enabling integrated linkage between equipment monitoring and plant-wide automation control.

4. Local Visualization and Status Indication The front panel integrates a visual display screen, allowing real-time viewing of measured values, alarm limits, and module operating status for each monitoring channel without connecting to a host computer, facilitating quick assessment of equipment conditions by field maintenance personnel.

Multiple LED status indicators visually display the module's operating, communication, alarm, and fault statuses, enabling rapid location of system anomalies and improving maintenance efficiency.

5. Industrial-grade stability and compatibility

Operating temperature range: -20℃ to +70℃. Powered by a 24VDC industrial power supply, it features overvoltage, overcurrent, and electromagnetic interference protection, making it suitable for harsh industrial environments with high temperature, high humidity, and strong vibration. It supports continuous and stable operation 24/7.

Modular plug-in design, dimensions 86mm×100mm×35mm, weight 170g. Compatible with the entire VM600 standard rack series, including ABE040 and ABE042, offering strong interchangeability and facilitating system expansion and spare parts replacement.

Main Applications and Scenarios

1. Core Monitoring and Protection of Large Rotating Machinery

As the core of the VM600 monitoring system for critical rotating machinery such as steam turbines, gas turbines, hydro generators, centrifugal compressors, pump sets, and fans, it works in conjunction with monitoring cards to achieve real-time monitoring of key parameters such as shaft vibration, shaft displacement, speed, and differential expansion. Based on preset thresholds, it triggers multi-level alarms or emergency shutdown protection to prevent catastrophic failures such as shaft damage, blade breakage, and bearing failure, ensuring continuous and safe equipment operation.

2. Data Interaction Hub for Industrial Automation Systems

In industries such as power, petrochemicals, metallurgy, and natural gas transportation, it serves as the communication interface between the VM600 monitoring system and upper-level control systems such as DCS, PLC, and SCADA. It standardizes and uploads equipment vibration, displacement, and temperature status data, while simultaneously receiving control commands from upper-level systems, enabling coordinated linkage between equipment monitoring and plant-wide automation control, supporting intelligent factory operation and maintenance management.

3. Core of the Equipment Condition Monitoring and Fault Early Warning Platform

Working with VM600 MPSx and VibroSight professional analysis software, it stores and processes long-term monitoring data. Through trend analysis, spectrum analysis, and order analysis, it enables early fault warnings for equipment, providing data support for preventative maintenance and predictive repair, reducing unplanned downtime losses, and extending equipment lifespan.

4. System Integration Applications Under Harsh Operating Conditions

Widely used in high-temperature, high-humidity, strong electromagnetic interference, and strong vibration industrial environments such as power plant turbine halls, petrochemical refining units, metallurgical rolling mills, and aerospace test benches. With its wide temperature adaptability, high anti-interference capability, and modular design, it adapts to the system integration needs of various complex operating conditions. It also supports multi-rack cascading to meet the deployment requirements of multi-point, distributed monitoring for large units.

Email: xmxblynn@163.com

Phone: +86 18059884797

Send Inquiry to This Supplier

You May Also Like

-

Honeywell CC-PCF901 Control Firewall ModuleUS$ 10000 - 15000MOQ: 1 Set

-

Honeywell CC-PAIM01 Low-level Analog Input ModuleUS$ 10000 - 15000MOQ: 1 Set

-

Honeywell CC-PAIX01 High-density Analog Input ModuleUS$ 3500 - 4000MOQ: 1 Set

-

Honeywell CC-PAOH51 HART ANALOG OUTPUT MODULEUS$ 10000 - 15000MOQ: 1 Set

-

Honeywell CC-PDlL01 DIGITAL INPUT MODULEUS$ 10000 - 15000MOQ: 1 Set

-

Honeywell CC-PRB01 Industrial Automation ModuleUS$ 10000 - 15000MOQ: 1 Set

-

Honeywell CC-PSP401 Protection ModuleUS$ 10000 - 15000MOQ: 1 Set

-

CC-PFB801 51410087-176 Fieldbus Interface ModuleUS$ 10000MOQ: 1 Set

-

Honeywell CC-PUIO31 16pcs Universal Input Output ModuleUS$ 10000MOQ: 1 Set

-

Honeywell CC-PCNT05 Control Network ModuleUS$ 10000 - 15000MOQ: 1 Set