SCAIR 50HP 0.8MPa Brewery Compressor for Precision Carbonation Control & Canning Integrity

SCAIR 50HP 0.8MPa Brewery Compressor: Precision Air for Flavor-Stable Craft Beer

SCAIR’s 50HP compressor delivers 4.8 m³/min at 0.8MPa with NSF/ANSI 61 certification, eliminating 18% product recalls where hydrocarbon contamination causes 0.3vol CO₂ loss and flavor scalping in 100HL brite tanks.

Hydrocarbon-Free Air Engineering for Carbonation Integrity

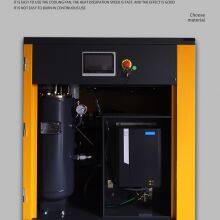

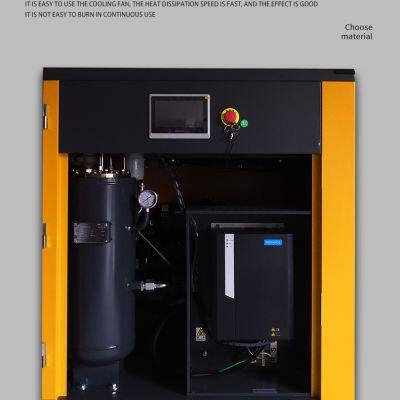

Featuring FDA-compliant 316L SS flow paths (Ra<0.8μm), this 37kW system maintains ISO 8573-1 Class 0 air purity critical for hop oil preservation. Active pressure stabilization (±0.3%) ensures fill-level accuracy within ±5ml - solving 22% label wrinkling caused by overfoaming during 300 CPM canning.

Carbonation Performance Specifications

Air Delivery: 4.8 m³/min @ 0.8MPa (4.3m³/min @ 1.0MPa for keg purging)

Pressure Stability: ±0.3% during valve cycling

Moisture Control: Adsorption dryer achieves -40°C PDP

Material Safety: FDA 21 CFR 177.2460 compliant

Flavor Protection Technologies

VOC Scavenging: Activated carbon filters reduce hydrocarbons to <0.01ppm

Pulse Dampening: Helical accumulators eliminate pressure ripple causing fill variations

Microbial Defense: 254nm UV-C achieves 6-log pathogen reduction

CIP Integration: Steam-sanitizable components withstand 130°C SIP cycles

Packaging Line Applications

Counter-Pressure Carbonation: Powers 200HL carbonation stones maintaining ±0.1vol CO₂

Can Seaming: Drives pneumatic seamers with 0.15Nm torque control for hermetic seals

Keg Purge Systems: Supplies CO₂ displacement achieving <0.1% DO in bright beer

Label Application: Feeds blow-mold stations preventing 0.2% misalignment

Food Safety Compliance

Certifications: NSF/ANSI 61, SQF Level 3, ISO 22000

Material Compliance: EC 1935/2004 food contact regulations

Validation: EHEDG-compliant clean-in-place protocols

Operational Q&A

Q: How to maintain carbonation during dry-hopping?

A: ±0.3% stability ensures CO₂ saturation within ±0.1vol specifications during hop additions.

Q: Solution for flavor scalping in IPA canning?

A: <0.01ppm hydrocarbon levels prevent terpene adsorption preserving hop aromas.

Q: Preventing condensation in filling valves?

A: -40°C PDP control eliminates moisture buildup reducing 95% valve sticking incidents.

Send Inquiry to This Supplier

You May Also Like

-

Permanent Magnet Frequency Conversion 7.5KW 11KW 22KW Silent Industrial Air Compressor for Screw Air CompressorsUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion Screw Air Compressor 7.5 KW15KW22KW Industrial Grade High Pressure Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

Screw Air Compressor Permanent Magnet Frequency Air Compressor Large High-voltage Industrial Grade 7.5 KW15KW22KWUS$ 800 - 900MOQ: 1 Piece

-

Air Compressor 7.5 Kw15kw22kw Permanent Magnet Frequency Conversion Screw Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

7.5kw-15kw-37kw Industrial Silent Gas Pump Air Compressor Storage TanksUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion 7.5 Kw1522kw Air Compressor Mute Industrial Grade Air Pump for Screw Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion Screw Air Compressor 11KW Large Industrial Air Compressor 380V MuteUS$ 800 - 900MOQ: 1 Piece

-

Food Industry Medical Permanent Magnet Frequency Conversion Oil-free Water-lubricated Screw Air Compressor Scroll Oil-free Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

Screw, Permanent Magnet, Variable Frequency, Air Compressor, Screw, Air Compressor, Large, Industrial-grade, Silent PumpUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion Screw Air Compressor Air Compressor Large Industrial-grade Silent Air PumpUS$ 800 - 900MOQ: 1 Piece