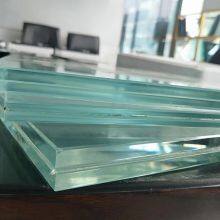

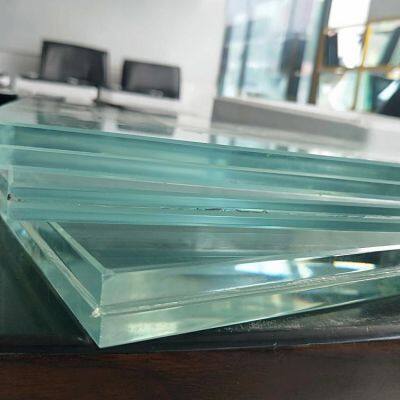

Triple Laminated Safety Glass for Walk-on Floor Panels - Impact Resistant Solution

As a specialized manufacturer since 2003, QinHuangDao LianYiDing Glass leverages its 5,000-10,000 sqm facility and team of 201-300 professionals to engineer premium Triple Laminated Safety Glass for Walk-on Floor Panels. This solution delivers unmatched structural integrity and impact resistance for demanding architectural applications, ensuring occupant safety through rigorous manufacturing processes certified under ISO9001 and ISO14000 standards.

Our triple-layer laminated construction transforms standard glass into a robust, walkable surface capable of withstanding significant loads and accidental impacts. Engineered for architects and builders seeking transparent flooring without compromising safety, this product combines advanced material science with practical functionality. With annual exports reaching global markets including North America, Europe, and Asia through ports like Tianjin and Dalian, we bring proven reliability to complex projects worldwide.

Core Technical Advantages:

- Triple-Layer Defense: Three sheets of tempered glass bonded with advanced PVB/SGP interlayers create a monolithic unit that maintains structural cohesion even upon impact.

- Engineered Load Distribution: Evenly disperses point loads across the entire panel surface, preventing localized stress fractures.

- Fragment Retention: Lamination technology ensures glass fragments adhere to the interlayer if breakage occurs, eliminating fall-through hazards.

- Customizable Safety Surfaces>:

- Environmental Resilience: Maintains performance stability across temperature ranges from -40°C to 80°C.

- Acoustic & UV Control: PVB interlayers provide inherent sound dampening and block 99% of UV radiation.

Performance Specifications:

| Parameter | Standard Value | Testing Standard |

| Impact Resistance | Survives 190ft-lb impact | ASTM E1886 |

| Uniform Load Capacity | Up to 6.0 kPa (125 psf) | EN 12600 |

| Deflection Limit | ≤ L/175 at design load | ANSI Z97.1 |

| Surface Roughness (Anti-slip) | R10 - R13 (DIN 51130) | Customizable |

Architects and contractors benefit from:

- Reduced structural framing requirements due to superior load distribution

- Elimination of secondary protective barriers in public spaces

- Seamless integration with structural silicone or point-supported systems

- Simplified maintenance with chemical-resistant surfaces

- Design flexibility with options for printed interlayers or LED integration

Backed by ISO-certified manufacturing across our Hebei-based facility, we guarantee consistent quality control from raw material selection to final packaging. With 20+ years of exporting expertise to 7 global regions, including demanding markets like Northern Europe and North America, our solutions meet international building codes. Each shipment undergoes rigorous pre-shipment inspection at Tianjin, Dalian, or Qinhuangdao ports, ensuring your project receives glass engineered to perform under pressure. Contact us today for technical drawings and project-specific load calculations.

Frequently Asked Questions:

Q1: What is the maximum span for unsupported panels?

A: Maximum spans vary by thickness and loading. Our 24mm panels typically span 1.2m with point supports. We provide engineering support for custom configurations.

Q2: Can this glass withstand rolling loads like equipment trolleys?

A: Yes, when properly specified. Our 30mm variant with SGP interlayer supports rolling loads up to 500kg. Surface hardness exceeds 6 Mohs.

Q3: How is anti-slip performance achieved?

A: Through ceramic frit patterns, acid etching, or structural texturing. We match slip ratings to local building regulations (DIN 51130/UK Building Regs).

Q4: What's the lead time for custom sizes?

A: Standard sizes ship in 15 days. Custom projects require 25-35 days including engineering validation. Expedited production is available.

Q5: Does the lamination affect optical clarity?

A: Our low-iron glass with optically clear interlayers maintains >92% light transmission. Haze is controlled below 1% per ASTM D1003.

Q6: Can damaged panels be repaired?

A: Surface scratches can be polished, but structural damage requires replacement. We recommend keeping spare panels for critical applications.

Send Inquiry to This Supplier

You May Also Like

-

6.38mm-12.76mm PVB Film Laminated Glass in Clear and Tinted OptionsNegotiableMOQ: 500 Square Meters

-

200x100x50mm Decorative Glass Blocks for Indoor Building and Design ApplicationsNegotiableMOQ: 500 Square Meters

-

Clear and Colored PVB Laminated Tempered Glass in 6.38mm-12.76mm Thickness OptionsNegotiableMOQ: 500 Square Meters

-

Laminated GlassUS$ 1 - 10MOQ: 10 Square Meters

-

6.38mm Laminated GlassUS$ 1 - 10MOQ: 1 Piece

-

6.38mm Laminated GlassUS$ 1 - 10MOQ: 1 Piece

-

UV-Blocking Laminated Glass With 99% UV Rejection for Museum DisplaysUS$ 1 - 10MOQ: 1 Piece

-

Laminated Glass With 10-Year Warranty Against Delamination and YellowingUS$ 1 - 10MOQ: 1 Piece

-

Bullet-Resistant Laminated Glass Panel With UL 752 Level 3 CertificationUS$ 1 - 10MOQ: 1 Piece

-

Hurricane-Impact Laminated Glass Passes Miami-Dade County TAS 201/202US$ 1 - 10MOQ: 1 Piece