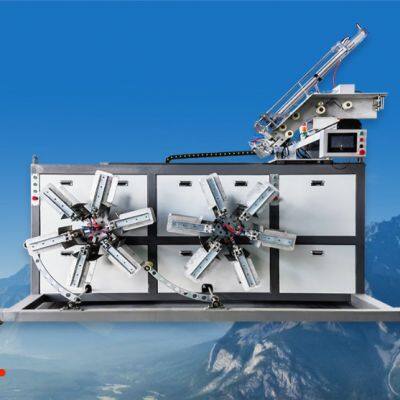

Semi Automatic Pipe Coiler With Pipe Range From 16mm/20mm/25mm/32mm

introduction of PE 16-32mm pipe coiler

The Double-Station Pipe Coiler Machine is an independent R&D product of BAKELITE . Adopting a servo-driven traverse system, it achieves precise control over pipe displacement, which in turn ensures the production of uniform, well-arranged finished pipe coils.

The equipment is suitable for the following pipeline production lines:

-High speed PE-RT Pipe Production Line,

-High Speed Round Drip Irrigation Pipe Machine,

-High Speed PEXB Pipe Machine

-PEXB/EVOH Pipe Making Machine

-PERT/EVOH Pipe Production Machine

-PEX-AL-PEX Pipe Making Machine

-PERT-AL-PERT Pipe Making Machine

A tension controller is incorporated to detect pipe tension, enabling automatic adjustment of pipe winding speed.

Featuring user-friendly operation, the machine is controlled by a Siemens PLC system and achieves synchronous operation with the entire production line.

Double-Station Pipe Coiler Process Flow Chart

Process Description

Automatic Feeding: The equipment automatically feeds and positions the pipe to be processed without manual intervention, ensuring continuous process initiation.

Servo Traversing: Precisely controls pipe displacement through the servo traverse unit to achieve uniform pipe arrangement and ensure coil neatness.

Coil Changing: Dual-station switching, automatically switches to the other station after one coil is wound, realizing continuous production and reducing downtime.

Cutting: Automatically cuts the pipe according to the preset length, and the finished product enters the next link after cutting to ensure dimensional accuracy.

Product Parameters

Technical Parameter

| Application | Automatic Coiling Requirements for PE Pipe with Outer Diameters of 16mm, 20mm, 25mm, and 32mm |

| Equipment pipe contact surface | Galvanizing process |

| Production Specification Range | 16-32mm |

| Adjustable roll width range | 250-400mm |

| Adjustable range of inner diameter for roll winding | 440mm-550mm |

| Production Efficiency Requirements | Maximum winding speed: 30 m/min |

| Equipment Size Requirements | 3800mm × 2000mm × 1800mm (Length × Width × Height) |

| Equipment Appearance/Color Requirements | Body Gray, Protective Panel and Electrical Box Off-White (Color Code 7035) |

| Equipment Control Mode | Aluminum Alloy Control Cabinet with PLC Control |

| Other Basic Characteristics | Control system comprising HMI + PLC + servo motor + encoder + solenoid valve + pneumatic cylinder |

Supporting Conditions and Environment

| Installation Environment | Indoor |

| Power Supply | AC 380V |

| Humidity | 85% non-condensing |

| Temperature | -20/45°C |

| Installed capacity | 6kw |

| Power Supply Method | 3P+N+PE |

| Supply voltage, frequency | Three-phase 380±10%, 50Hz |

| Cooling water: Water temperature ≤15°C; Water pressure ≥0.3 MPa | None |

| Compressed air: Pressure > 0.6 MPa | Not less than 1.0 cubic meters per hour |

Main Technical Specifications of the Equipment

| Equipment name | Brand name |

| Pneumatic components | AIRTAC |

| Proximity switches, photoelectric switches | Chinese well known brand |

| Bearings, guide rods, sliders | Chinese well known brand |

| contactor | Chint |

| Circuit breaker | Chint |

| PLC | Weichuang |

| Touchscreen | Kunlun Tongtai |

| Servo motor, driver | Weichuang |

| Reducer Motor | RMT Ruimait |

| Switching Power Supply | Chinese well known brand |

| Buttons, indicator lights | Chinese well known brand |

| Warning light | DC24V Blue-Red-Green-Blue Four-Color LED Strip with Sound |

Detailed Photos

Coiled pipe

Partner

Company Profile

Qingdao Bakelite Intelligent Technology Co., Ltd. is a comprehensive industrial automation equipment manufacturing enterprise integrating R&D, manufacturing, sales and service. It is mainly engaged in the R&D and production of fully automatic strapping and winding machines for plastic pipes, rubber pipes and metal coils, providing integrated solutions for ring packaging, as well as the design, R&D and production of industrial manipulators and automatic assembly lines. The company offers integrated smart factory solutions covering pipe winding, strapping, film wrapping, palletizing and AGV transportation.

Equipped with an independent R&D and design team specialized in mechanical industrial automation, Bakelite is an industrial automation system integration company with 15 years of in-depth experience in the industry. Adhering to the business philosophy of "Winning by Quality and Service, Strengthening through Integrity and Win-Win Cooperation", the equipment produced by the company is widely supporting large domestic pipe extrusion equipment manufacturers and large coil manufacturing enterprises, and has won consistent praise from the industry.

Certifications

FAQ

1.Are you manufacturer or trading company?

We are manufacturer of pipe coiler in China for more than 20 years.

2. What price terms you offer?

FOB, CIF, EXW and other price terms based on your kind request.

3.Is installation and stuff training available from you?

Yes, our engineers will guide machine installation and train your workers.

4. How long will I receive the quotation?

Once we know the raw material, final product dimension and the special requirements, we will provide you a detailed quotation within 24 hours.

5. How do I get response quickly?

If you send inquiry to contact us, we promise to reply to you within 8 hours!

Send Inquiry to This Supplier

You May Also Like

-

Fully Automatic 16-32mm Pipe Winding Machine Pipe CoilerUS$ 12000MOQ: 1 Set

-

Automatic 16-32mm Pipe Coiler Winding Machine for Pipe Production LineUS$ 12000MOQ: 1 Set

-

Fully Automatic 16-32mm Pipe Winding Machine Pipe Coiler for HDPE Pipe LineUS$ 12000MOQ: 1 Set

-

Hdpe Automatic Pipe Coiling Machine SupplierUS$ 48990 - 189990MOQ: 1 Set

-

Automatic Pipe Coiler With Accumulator for High Speed PE-Rt Pipe MachineUS$ 48990 - 189990MOQ: 1 Set

-

Plastic Pipe Coiler Automatic Pipe Coiler/Plastic Pipe CoilerUS$ 48990 - 189990MOQ: 1 Set

-

Double Two Disk 16-63mm PPR Hot Cold Water Pipe CoilerUS$ 48990 - 189990MOQ: 1 Set

-

Double Disk 16/20/32/50/63mm Corrugated Pipe Drip Irrigation Pipe Auto Coilling MachineUS$ 48990 - 189990MOQ: 1 Set

-

Large Diameter 50mm-110mm Pipe Automatic Coilling Machine China SupplierUS$ 48990 - 189990MOQ: 1 Set

-

Double-station RTP Large Diameter Pipe Automatic Coilling Machine China SupplierUS$ 89990 - 289990MOQ: 1 Set