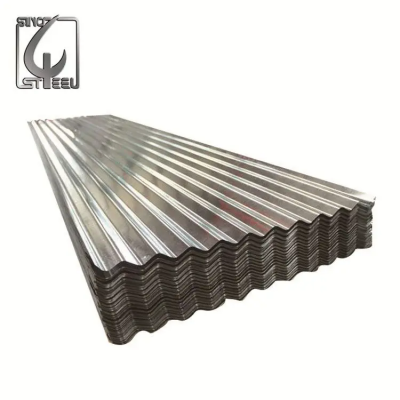

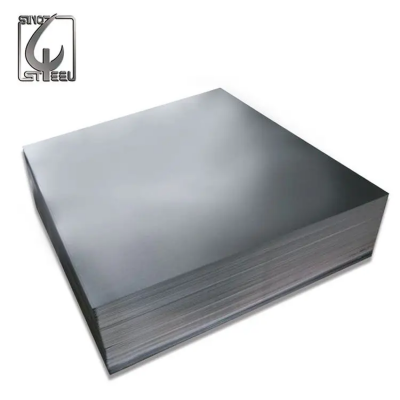

Cold Rolled Electrolytic Tinplate Steel Sheet DR8-DR10 With Bright/Stone Matt Finish

As a dedicated manufacturer since 2018, Shandong Sino New Material Co., Ltd. proudly produces high-quality cold rolled electrolytic tinplate steel sheets, designed for superior performance in demanding industrial applications. With our 10,000-30,000 square meter factory and annual export value of US$2.5 Million to US$5 Million, we ensure consistent supply to global markets including North America, Europe, and Asia. Our DR8-DR10 tinplate sheets feature bright or stone matt finishes, offering exceptional durability and aesthetic appeal for packaging solutions. Backed by ISO certifications and a team of 101-200 skilled professionals, we deliver products that meet stringent quality standards, shipped efficiently from ports like Qingdao and Shanghai.

Our cold rolled electrolytic tinplate steel sheets are engineered for excellence, providing numerous benefits to clients. Key features include:

- Enhanced Corrosion Resistance: The electrolytic tin coating protects against rust and chemical degradation, extending product lifespan in humid or corrosive environments.

- Superior Surface Finishes: Choose between a bright finish for a high-gloss, reflective appearance ideal for premium packaging, or a stone matt finish for a textured, non-slip surface that reduces glare and fingerprints.

- Precise Thickness Control: Available in DR8-DR10 grades, ensuring uniform thickness for consistent performance in forming and stamping processes.

- Eco-Friendly and Food-Safe: Made from recyclable materials, our tinplate is compliant with food contact standards, perfect for cans and containers.

Technical specifications highlight the product's reliability. Below is a summary of key parameters:

| Parameter | Value | Benefits |

|---|---|---|

| Thickness Range | DR8 (0.20mm) to DR10 (0.30mm) | Allows for lightweight yet strong constructions, reducing material costs. |

| Tin Coating Weight | Standard 2.8g/m² to 11.2g/m² | Ensures optimal solderability and barrier protection. |

| Tensile Strength | 280-420 MPa | Provides high durability for mechanical processing. |

| Surface Hardness | HR 30T 40-65 | Resists scratches and abrasions during handling. |

Clients gain significant advantages, such as reduced waste through efficient formability, lower maintenance costs due to long-term corrosion resistance, and versatility across industries like beverage cans, aerosol containers, and decorative items. Customization options include adjustable widths and lengths, ensuring a perfect fit for specific machinery or design requirements.

Trust in our proven expertise: Shandong Sino New Material Co., Ltd. serves over 10 global regions, including Southeast Asia and Western Europe, with ISO9000 and ISO19011:2000 certifications guaranteeing product integrity. Our overseas offices streamline logistics, and shipments from Qingdao, Tianjin, or Shanghai ensure timely delivery. Choose our tinplate sheets for reliable, high-performance solutions that enhance your packaging efficiency—contact us today for a quote or sample to experience the difference firsthand.

Frequently Asked Questions

Q: What does DR8-DR10 refer to in the product title?

A: DR8-DR10 indicates the thickness grade range, with DR8 approximately 0.20mm and DR10 around 0.30mm, suitable for various forming applications.

Q: How does the bright finish differ from stone matt?

A: The bright finish offers a shiny, reflective surface ideal for aesthetic packaging, while stone matt provides a textured, non-reflective look that minimizes glare and is easier to handle.

Q: What industries commonly use this tinplate steel?

A: It's widely used in food and beverage packaging, aerosol cans, chemical containers, and electronic components due to its corrosion resistance and formability.

Q: Are custom sizes available for orders?

A: Yes, we offer customizable widths and lengths to match your production needs; specifications can be discussed upon request.

Q: What certifications support your product quality?

A: Our tinplate sheets are manufactured under ISO9000 and ISO19011:2000 certifications, ensuring consistent quality and process control.

Q: How long is the typical lead time for shipments?

A: Lead times vary based on order volume and customization, but standard orders ship within 2-4 weeks from Qingdao, Tianjin, or Shanghai ports.

Q: Can I request samples before bulk ordering?

A: Absolutely, we provide samples for evaluation to help you verify the product's suitability for your application.

Q: What are the main advantages of electrolytic tin coating?

A: It enhances solderability, provides excellent barrier protection against corrosion, and ensures food safety for packaging uses.

Send Inquiry to This Supplier

You May Also Like

-

Electrolytic Tinplate Steel Coil SPTE SPCC With Bright Surface 2.8/2.8 5.6/5.6 CoatingNegotiableMOQ: 25 Tons

-

Electrolytic Tin Steel Coil MR & SPCC for Packaging and Industrial UseNegotiableMOQ: 25 Tons

-

Corrosion-Resistant DR8 SPCC MR A08AL SPTE Tinplate Steel Coil for LongevityNegotiableMOQ: 25 Tons

-

T1-T5 Electrolytic Tinplate Coil/Plate/Strip for Various Industrial ApplicationsNegotiableMOQ: 25 Tons

-

SPCC Grade Electrolytic Tinplate Coil With Differential Coating 1.1/2.8 for Metal CansNegotiableMOQ: 25 Tons

-

BA CA TinPlate Electrolytic Tin Metal Tinplate Steel Tinplate CoilUS$ 845MOQ: 25 Tons

-

Tinplate Steel Tinplate Metal BA Tin Coated Steel Strip Tinplate StripUS$ 842.00 - 859.00MOQ: 25 Tons

-

Tinplate Steel Coil Coated Tin Steel Tinplate Metal CA Tinplate CoilUS$ 840.00 - 852.00MOQ: 25 Tons

-

T1-T5 Hardness MR SPCC Tinplate Sheet Tinplate for Can Tinplate SteelUS$ 835.00 - 851.00MOQ: 25 Tons

-

Tinplate Steel Coil Tinplate Metal Tinplate Strip Steel Coated Gloden Tin TripUS$ 850.00 - 863.00MOQ: 25 Tons