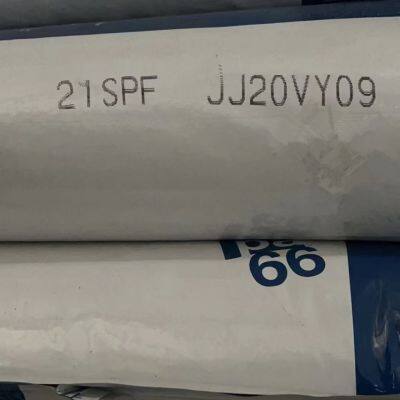

Premium Dupont Vydyne 21SPF PA66 Raw Material for High-Performance Applications

As Suzhou Yifuhui New Material Co., Ltd., a trusted trading partner established in 2020 with annual exports valued at US$10-50 million, we proudly present our premium Dupont Vydyne 21SPF PA66 raw material. Sourced directly from leading manufacturers, this engineering-grade polyamide 66 resin delivers exceptional performance for critical applications where reliability under extreme conditions is non-negotiable. Our global logistics network ensures timely delivery from major Chinese ports including Shanghai, Ningbo, and Qingdao to industrial hubs across North America, Europe, Asia, and beyond.

Engineered to surpass conventional nylon materials, Vydyne 21SPF offers superior mechanical properties and thermal stability that translate directly into longer component lifespan and reduced maintenance costs. Unlike generic PA66 grades, this formulation maintains dimensional integrity under continuous high-stress loads while resisting chemical degradation from oils, fuels, and coolants. For manufacturers seeking to enhance product durability without compromising on processability, this material provides an optimal balance between performance and manufacturability.

The core advantages of this advanced polymer include:

- Exceptional Strength-to-Weight Ratio: Enables lightweight yet structurally robust components ideal for automotive under-hood applications and moving mechanical assemblies.

- Enhanced Thermal Performance: Withstands continuous operating temperatures up to 220°C (428°F) without significant property degradation.

- Superior Chemical Resistance: Maintains integrity when exposed to automotive fluids, industrial lubricants, and hydraulic oils.

- Excellent Processability: Optimized melt flow characteristics ensure consistent molding results with reduced cycle times.

Below are key technical specifications that define the performance envelope of Vydyne 21SPF:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 85 MPa | ASTM D638 |

| Flexural Modulus | 2900 MPa | ASTM D790 |

| HDT @ 1.82 MPa | 220°C | ASTM D648 |

| Melt Flow Rate | 12 g/10 min | ASTM D1238 |

| Moisture Absorption | 2.5% (saturated) | ASTM D570 |

This material demonstrates particular advantages in demanding environments such as:

- Automotive Systems: Throttle bodies, intake manifolds, cooling system components, and electrical connectors where heat and chemical resistance are critical.

- Electrical Engineering: Circuit breakers, switch housings, and relay components requiring UL94 V-0 flammability rating (optional).

- Industrial Machinery: Gears, bearings, and wear pads subjected to high friction and mechanical stress.

- Consumer Appliances: Power tool housings and internal components needing impact resistance.

With distribution channels spanning 15 major global markets including North America, Western Europe, and Southeast Asia, we've established a reputation for supplying consistent-quality polymers to Fortune 500 manufacturers. Our strategic location in Suzhou's industrial hub enables rigorous quality control protocols from material sourcing to shipment preparation. The 25kg moisture-resistant packaging ensures product integrity during transit, while flexible containerization options are available for high-volume orders.

Why choose our Vydyne 21SPF? Beyond the material's inherent technical superiority, we offer unparalleled supply chain reliability with documentation transparency and technical support. Our clients benefit from:

- Batch-to-batch consistency verified through third-party testing reports

- Just-in-time delivery programs to minimize inventory costs

- Technical consultation on processing parameters and mold design

- Competitive pricing structures for long-term partnerships

Join numerous satisfied clients across automotive, electronics, and industrial sectors who leverage our materials expertise to enhance their product performance. Contact our Jiangsu-based team today for material samples, technical data sheets, or customized formulation inquiries. We're ready to support your next high-performance application with polymer solutions that meet exacting global standards.

Frequently Asked Questions:

Q1: Is this material suitable for food-contact applications?

A: Our standard Vydyne 21SPF isn't certified for food contact. Food-grade variants may be available upon request with proper documentation.

Q2: What are the storage recommendations for unopened bags?

A: Store in original packaging below 40°C with relative humidity under 50%. Avoid direct sunlight and use within 12 months for optimal performance.

Q3: Can you provide flame-retardant grades?

A: Yes, we offer UL94 V-0 compliant versions with tailored flame retardancy. Request separate technical data sheets for these formulations.

Q4: What drying parameters are recommended before processing?

A: Dry at 80-90°C for 4-6 hours to achieve moisture content below 0.2%. Use dehumidifying hopper dryers for best results.

Q5: Do you offer custom compounding services?

A: We provide value-added services including glass fiber reinforcement, mineral filling, and impact modification based on minimum order quantities.

Q6: What's the lead time for container shipments to Europe?

A: Standard shipments from Qingdao to Rotterdam take approximately 35 days. Expedited options are available.

Q7: Can I get material samples for mold trials?

A: Yes, we provide 2kg evaluation samples with material certification. Processing guidelines accompany all sample shipments.

Q8: How does Vydyne 21SPF compare to PA6 materials?

A: This PA66 grade offers approximately 20-30% higher heat resistance and better chemical stability than standard PA6, making it preferable for under-hood automotive applications.

Send Inquiry to This Supplier

You May Also Like

-

PA66 American Ascend 21SPC High Flow and High Rigidity is Used in Electronic AppliancesUS$ 2.98 - 3.03MOQ: 25 Kilograms

-

Hot Sales Engineering Plastic Wear-resistant High Flow High Rigidity for Automotive Parts PA66 21SPC Polyamide Plastics PelletUS$ 2.98 - 3.03MOQ: 25 Kilograms

-

Ascend PA66 Vydyne 21SPC / 21SPC1 Polyamide 66 Nylon66 Resin Ascend 21SPC / 21SPC1US$ 2.98 - 3.03MOQ: 25 Kilograms

-

Ascend PA66 Vydyne 21SPC/21SPC1 Polyamide 66 Nylon66 Resin Engineered ThermoplasticsUS$ 2.98 - 3.03MOQ: 25 Kilograms

-

Engineering Plastics Polyamide Resin Translucent Pure Resin Injection Molding General Purpose Grade PA66 ASCEND 21SPCUS$ 2.98 - 3.03MOQ: 25 Kilograms

-

Hot Sale Food Contact Grade PA66 21SPC High Melting Point Plastic Particles/chemical Resistant Nylon 66 Resin for Cable TiesUS$ 2.98 - 3.03MOQ: 25 Kilograms

-

Ascend PA66 Vydyne 21SPC Polyamide 66 Nylon66 Resin Engineered ThermoplasticsUS$ 2.98 - 3.03MOQ: 25 Kilograms

-

Polyamide 66 Ascend Vydyne 21SPC High Strength Rigidity Good Toughness High Melt Point Virgin Pa Plastic Granule Pa6 Pa66US$ 2.98 - 3.03MOQ: 25 Kilograms

-

PA66 American Ascend Engineering Plastic Wear-resistant Oil Resistant High Flow High Rigidity for Bearing PA66 21SPCUS$ 2.98 - 3.03MOQ: 25 Kilograms

-

ASCEND Polyamide Resin Injection Molding Grade PA66 Engineering Plastics General Purpose 21SPCUS$ 2.98 - 3.03MOQ: 25 Kilograms