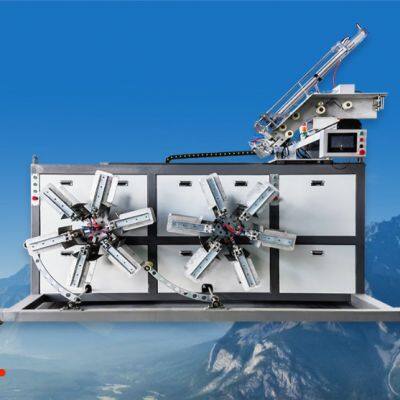

Semi-Automatic Pipe Coiler With Cutting and Pipe Stacking

introduction of PE 16-32mm pipe coiler

The Double-Station Pipe Coiler Machine is an independent R&D product of BAKELITE . Adopting a servo-driven traverse system, it achieves precise control over pipe displacement, which in turn ensures the production of uniform, well-arranged finished pipe coils.

The equipment is suitable for the following pipeline production lines:

-High speed PE-RT Pipe Production Line,

-High Speed Round Drip Irrigation Pipe Machine,

-High Speed PEXB Pipe Machine

-PEXB/EVOH Pipe Making Machine

-PERT/EVOH Pipe Production Machine

-PEX-AL-PEX Pipe Making Machine

-PERT-AL-PERT Pipe Making Machine

A tension controller is incorporated to detect pipe tension, enabling automatic adjustment of pipe winding speed.

Featuring user-friendly operation, the machine is controlled by a Siemens PLC system and achieves synchronous operation with the entire production line.

Technical Parameter

| Application | Automatic Coiling Requirements for PE Pipe with Outer Diameters of 16mm, 20mm, 25mm, and 32mm |

| Equipment pipe contact surface | Galvanizing process |

| Production Specification Range | 16-32mm |

| Adjustable roll width range | 250-400mm |

| Adjustable range of inner diameter for roll winding | 440mm-550mm |

| Production Efficiency Requirements | Maximum winding speed: 30 m/min |

| Equipment Size Requirements | 3800mm × 2000mm × 1800mm (Length × Width × Height) |

| Equipment Appearance/Color Requirements | Body Gray, Protective Panel and Electrical Box Off-White (Color Code 7035) |

| Equipment Control Mode | Aluminum Alloy Control Cabinet with PLC Control |

| Other Basic Characteristics | Control system comprising HMI + PLC + servo motor + encoder + solenoid valve + pneumatic cylinder |

Supporting Conditions and Environment

| Installation Environment | Indoor |

| Power Supply | AC 380V |

| Humidity | 85% non-condensing |

| Temperature | -20/45°C |

| Installed capacity | 6kw |

| Power Supply Method | 3P+N+PE |

| Supply voltage, frequency | Three-phase 380±10%, 50Hz |

| Cooling water: Water temperature ≤15°C; Water pressure ≥0.3 MPa | None |

| Compressed air: Pressure > 0.6 MPa | Not less than 1.0 cubic meters per hour |

Main Technical Specifications of the Equipment

| Equipment name | Brand name |

| Pneumatic components | AIRTAC |

| Proximity switches, photoelectric switches | Chinese well known brand |

| Bearings, guide rods, sliders | Chinese well known brand |

| contactor | Chint |

| Circuit breaker | Chint |

| PLC | Weichuang |

| Touchscreen | Kunlun Tongtai |

| Servo motor, driver | Weichuang |

| Reducer Motor | RMT Ruimait |

| Switching Power Supply | Chinese well known brand |

| Buttons, indicator lights | Chinese well known brand |

| Warning light | DC24V Blue-Red-Green-Blue Four-Color LED Strip with Sound |

Qingdao Bakelite Intelligent Technology Co., Ltd. is a comprehensive industrial automation equipment manufacturing enterprise integrating R&D, manufacturing, sales and service. It is mainly engaged in the R&D and production of fully automatic strapping and winding machines for plastic pipes, rubber pipes and metal coils, providing integrated solutions for ring packaging, as well as the design, R&D and production of industrial manipulators and automatic assembly lines. The company offers integrated smart factory solutions covering pipe winding, strapping, film wrapping, palletizing and AGV transportation.

Equipped with an independent R&D and design team specialized in mechanical industrial automation, Bakelite is an industrial automation system integration company with 15 years of in-depth experience in the industry. Adhering to the business philosophy of "Winning by Quality and Service, Strengthening through Integrity and Win-Win Cooperation", the equipment produced by the company is widely supporting large domestic pipe extrusion equipment manufacturers and large coil manufacturing enterprises, and has won consistent praise from the industry.

1.what is an automatic coiler and how does it improve production efficiency?

An automatic coiler is an industrial machine designed to transform continuous pipe or tubing into perfectly wound ribbon coils. It integrates seamlessly with your production line, automatically counting lengths and executing precise cuts. This advanced equipment ensures consistent coil formation while maintaining product integrity. By automating the coiling process, manufacturers achieve higher throughput, reduce labor costs, and minimize product damage. The system's intelligent design allows for smooth material transfer and reliable operation throughout extended production runs.

2. How does the automatic coil ejection system ensure operator safety?

Our automatic coiler prioritizes operator safety through multiple protective features. The system includes interlocked safety doors that separate operators from the winding mechanism during operation. When the coiling cycle completes, the machine automatically ejects finished coils onto designated trolleys or receiving tables through the front unloading system. This design eliminates manual handling of heavy coils and prevents exposure to moving parts. Safety sensors and emergency stop systems provide additional protection, ensuring compliance with international industrial safety standards for pipe coiling equipment.

3.What types of materials and pipe sizes can your automatic coilers handle?

Our automatic coiling machines accommodate diverse material types and dimensional specifications. They efficiently process various piping materials including PVC, polyethylene, copper tubing, and flexible metal conduits. Standard models handle pipe diameters from 6mm to 50mm, with custom solutions available for specialized applications. The coiling systems can produce ribbon coils with diameters ranging from 800mm to 2000mm, tailored to your storage and shipping requirements. Each machine is engineered to maintain consistent coil tension and prevent material deformation throughout the winding process.

4. How do I select the right automatic coiler for my production line?

Choosing the optimal automatic coiler requires evaluating several key factors. Consider your production volume, pipe material characteristics, required coil dimensions, and integration needs with existing equipment. Our engineering team assesses your specific application to recommend the most suitable coiler series. We analyze your automation goals, available floor space, and desired connection to downstream processes like automated storage systems. With multiple coiler configurations available, we ensure perfect compatibility with your production chain while maximizing automation benefits and return on investment.

5. Can automatic coilers integrate with existing production automation and logic control systems?

Yes, our automatic coilers feature advanced integration capabilities for seamless connection to your production automation ecosystem. They communicate with upstream and downstream equipment using standard industrial protocols including PROFIBUS, Ethernet/IP, and Modbus TCP. The coiler's control system interfaces with production line computers for automatic length counting, cutting commands, and production data logging. This integration enables complete automation from raw material feeding through to coiled product handling, including connection to automated storage and retrieval systems for uninterrupted material flow throughout your facility.

6. What maintenance requirements should we expect for automatic coiling equipment?

Automatic coilers require minimal but regular maintenance to ensure optimal performance. Daily maintenance involves visual inspections and cleaning of critical components (approximately 10-15 minutes). Weekly tasks include checking tension systems, verifying sensor alignment, and lubricating moving parts (30-45 minutes). Monthly maintenance encompasses thorough inspection of wear components, electrical system verification, and software updates (2-3 hours). We provide comprehensive maintenance schedules, operator training, and remote support services. Most maintenance activities can be performed during planned production breaks, minimizing impact on your manufacturing operations.

Send Inquiry to This Supplier

You May Also Like

-

16-32mm Pipe Production Machine With Coil Winder MachineUS$ 12000 - 12500MOQ: 1 Set

-

Pipe Winding Machine With HDPE Pipe MachineUS$ 12000 - 12500MOQ: 1 Set

-

Pipe Production Machine With Rewinding MachineUS$ 12000 - 12500MOQ: 1 Set

-

Plastic Pipe Extrusion Machine With Coiling MachineUS$ 12000 - 12500MOQ: 1 Set

-

Plastic Pipe Extrusion Machine With Coil Winding MachineUS$ 12000 - 12500MOQ: 1 Set

-

16-32mm Plastic Pipe Production Line With Pipe Coiler MachineUS$ 12000MOQ: 1 Set

-

16-32mm Plastic Pipe Production Line With Winding MachineryUS$ 12000 - 12500MOQ: 1 Set

-

16-32mm Plastic Pipe Production Line With Pipe WinderUS$ 12000 - 12500MOQ: 1 Set

-

Two Station Plastic Pipe Winder/Plastic Pipe CoilerUS$ 12000 - 12500MOQ: 1 Set

-

Efficient Po Tube Extrusion Line Pipe CoilerUS$ 12000 - 12500MOQ: 1 Set