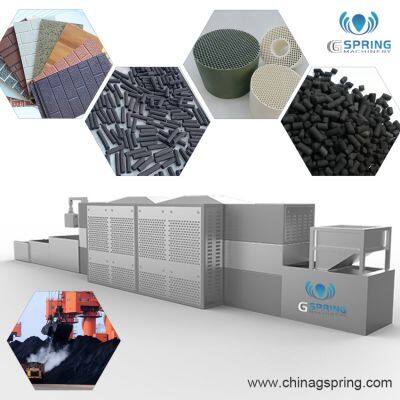

Industrial Microwave Dryer in Coal Industry

1. Efficient Moisture Removal:Microwave dryers can effectively remove both free and inherent moisture from coal without overheating the coal itself. This is because

microwave energy is preferentially absorbed by water molecules, allowing for controlled heating and drying without degrading the coal's coking properties.

2. Quality Improvement:By removing moisture, microwave drying can improve the quality of coal, making it more suitable for use in power generation and other industrial

processes. The process can also potentially reduce the levels of sulfur and other contaminants in the coal, which can enhance its environmental performance.

3. Energy Efficiency:Industrial microwave systems can be more energy efficient than traditional drying methods, particularly when electricity costs are low. The systems

can achieve high drying efficiencies, with some reports indicating energy conversion rates exceeding 95% for water removal.

4. Precise Control:Microwave drying systems offer precise control over the drying process, allowing operators to achieve a targeted moisture content range. This can be

particularly important in ensuring that the coal meets specific quality standards.

5. Continuous Processing:Industrial Microwave Dryers can be designed for continuous processing, making them suitable for large-scale coal drying operations. This can

help to improve the overall efficiency of coal processing plants.

6. Environmental Benefits:The use of microwave drying can reduce the environmental impact of coal processing by minimizing water usage and the release of contaminants.

The process can also potentially recover clean water as a byproduct.

7. Versatility:Microwave drying technology can be applied to a variety of coal types, including fine coal fractions, which can be challenging to dry using conventional methods.

This versatility makes microwave drying a valuable tool in the coal industry.

Industrial Microwave Dryer Application in Coal Industry

· Coal Preparation Plants:For the continuous drying of fine coal fractions to improve their quality and market value.

· Power Generation:To prepare coal for use in power plants, ensuring that it meets the necessary moisture content specifications.

·Steel Production:In steel mills, where coal is used as a reducing agent, microwave drying can improve the quality of the coal and enhance the efficiency of the steel production process.

· Environmental Remediation:By reducing the levels of sulfur and other contaminants in coal, microwave drying can help to mitigate the environmental impact of coal usage.

Except Coal Industry, Industrial Microwave Dryer also can be used for kinds of construction material, except normal wood & textile, but for some synthetic material,

like insulation board, fireproof material.

Technical Specifications

Machine Model | GS-20HMV | GS-40HMV | GS-60HMV | GS-100HMV | GS-200HMV |

Work Frequency | 2450±50MHZ | 2450±50MHZ | 2450±50MHZ | 2450±50MHZ | 2450±50MHZ |

Rated Apparent Power | ≤25KW | ≤50KW | ≤75KW | ≤120KW | ≤240KW |

Output Power | ≥20KW | ≥40KW | ≥60KW | ≥100KW | ≥200KW |

Dehydration Capacity | 16-20kg/hour | 30-40kg/hour | 48-60kg/hour | 80-100kg/hour | 160-200kg/hour |

Work Process Temperature | 70-200℃ | 70-200℃ | 70-200℃ | 70-200℃ | 70-200℃ |

Cooling Type | Water Cool/Air Cool | Water Cool/Air Cool | Water Cool/Air Cool | Water Cool/Air Cool | Water Cool/Air Cool |

Work Time | 24h Continuously Work | 24h Continuously Work | 24h Continuously Work | 24h Continuously Work | 24h Continuously Work |

Operation | PLC & Touch Screen | PLC & Touch Screen | PLC & Touch Screen | PLC & Touch Screen | PLC & Touch Screen |

Feeding Inlet Height | 40-100mm | 40-100mm | 40-100mm | 40-100mm | 40-100mm |

Belt Height | 60-1000mm | 60-1000mm | 60-1000mm | 60-1000mm | 60-1000mm |

Belt Running Speed | 0-4.5m/min or Customized | 0-4.5m/min or Customized | 0-4.5m/min or Customized | 0-4.5m/min or Customized | 0-4.5m/min or Customized |

Belt Width | 500±100mm | 800±100mm | 800±100mm | 1000±100mm | 1200±100mm |

Belt Material | Teflon Material or Customized | Teflon Material or Customized | Teflon Material or Customized | Teflon Material or Customized | Teflon Material or Customized |

Size | 8640×1220×2200mm | 10960×1500×2200mm | 13200×1500×2200mm | 15600×1700×2200mm | 22560×1900×2200mm |

Remark: Above parameter is for reference. All microwave dryer specific parameter need to be designed based on customer’s specific industrial request

China Gspring Machinery are the manufactuer of Industrial microwave dryer, we can supply different kinds of microwave drying machine, like batch microwave oven for lab

use or for small capacity industrial use, industrial automatic tunnel mircrowave dryer, vaccum dryer specially for food & pharma industry etc. We have more than 10 years

experience on export, export to all over the world, like USA, Canada, Russia, India, Sri Lanka, Turkey, Vietnam, Indonesia, Pakistan,Philippines, Brazil, Egypt, Czech, Singapore, Armenia, Iraq, Iran, Malaysia, Bangladesh, Mexico, Peru, Algeria, Poland, Thailand, Nepal, Azerbaijan etc.

Send Inquiry to This Supplier

You May Also Like

-

Salty Peanut Production LineNegotiableMOQ: 1 Set

-

Peanut Butter Production LineNegotiableMOQ: 1 Set

-

Continuous Chain Belt Nuts RoasterNegotiableMOQ: 1 Set

-

Vacuum FryerNegotiableMOQ: 1 Set

-

Batch Nuts RoasterNegotiableMOQ: 1 Set

-

Electromagnetic BakingNegotiableMOQ: 1 Set

-

Continuous FryerNegotiableMOQ: 1 Set

-

Batch FryerNegotiableMOQ: 1 Set

-

Centrifugal De-Oil MachineNegotiableMOQ: 1 Set

-

Air PeelerNegotiableMOQ: 1 Set