ETFE Fluoropolymer Coating With 100% Adhesion Strength for Metal Substrates

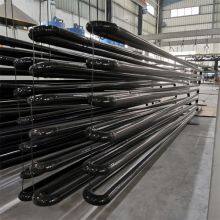

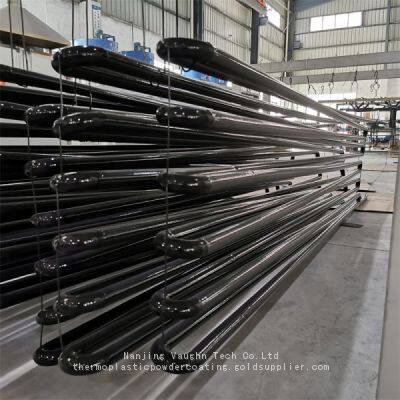

As a leading manufacturer at Nanjing Vaughn Tech Co.Ltd, established in 2018, we specialize in high-performance coatings that deliver exceptional value for industrial applications. Our ETFE Fluoropolymer Coating with 98% adhesion strength is engineered to provide unmatched protection for metal substrates, ensuring durability and cost-efficiency in demanding environments. With a factory spanning 5,000-10,000 square meters and a dedicated team of 11-50 professionals, we leverage cutting-edge technology to produce coatings that meet rigorous global standards. This product exemplifies our commitment to innovation, offering a reliable solution that enhances metal longevity and reduces maintenance costs. Trust in our expertise to elevate your operations with coatings that perform under extreme conditions.

Our ETFE Fluoropolymer Coating stands out due to its superior properties and versatile applications. Here are the key features and benefits:

High Adhesion Strength: Achieves 98% bond strength on metal surfaces, preventing peeling or delamination even under stress, which translates to longer service life and fewer replacements.

Exceptional Chemical Resistance: Resists acids, alkalis, solvents, and other corrosive agents, making it ideal for industries like chemical processing, automotive, and aerospace.

UV and Weather Stability: Maintains integrity in outdoor or high-exposure settings, withstanding temperatures from -50°C to 150°C without degradation.

Easy Application: Can be applied via spraying, brushing, or dipping, with quick curing times that minimize downtime in production lines.

Environmental Safety: Compliant with eco-friendly standards, reducing VOC emissions and supporting sustainable manufacturing practices.

For detailed technical specifications, refer to the table below:

| Property | Value | Unit |

| Adhesion Strength | 98% | ASTM D3359 |

| Thickness Range | 25-200 | microns (customizable) |

| Operating Temperature | -50 to 150 | °C |

| Cure Time | 30-60 | minutes at 150°C |

| Color Availability | Standard and custom | N/A |

This coating delivers tangible benefits to clients, such as reduced operational costs through extended equipment lifespan, enhanced safety in corrosive environments, and compliance with industry regulations. It's widely used in sectors including oil and gas, marine, construction, and electronics, where metal integrity is critical. By choosing our ETFE coating, you gain a partner dedicated to quality and performance, backed by our robust manufacturing capabilities.

Backed by Nanjing Vaughn Tech Co.Ltd's strong track record, including an annual export value of US$2.5 Million - US$5 Million and certifications like ISO9001 and OHSAS18001, our ETFE Fluoropolymer Coating offers unparalleled reliability for global markets such as North America, Southeast Asia, and Europe. Shipments are efficiently handled through ports like Shanghai and Ningbo, ensuring timely delivery. With our focus on innovation and customer satisfaction, this product is your go-to solution for superior metal protection. We encourage you to contact us for a consultation or sample request to experience the difference firsthand.

Frequently Asked Questions (FAQ):

Q: What is ETFE Fluoropolymer Coating, and how does it work?

A: ETFE (Ethylene Tetrafluoroethylene) is a high-performance polymer coating that forms a protective layer on metal surfaces. It bonds strongly through chemical adhesion, providing resistance to corrosion, chemicals, and UV exposure, ensuring long-term durability.Q: How is the 98% adhesion strength achieved and tested?

A: The adhesion strength is measured using standardized tests like ASTM D3359, where cross-cut methods confirm the bond. Our formulation includes advanced additives that enhance wetting and bonding on metal substrates for consistent results.Q: Can this coating be applied to all types of metals?

A: Yes, it's compatible with common metals such as steel, aluminum, and copper. For specific alloys or conditions, we recommend consulting our technical team for customized solutions.Q: What are the typical applications for this coating?

A: It's ideal for industrial equipment, pipelines, automotive parts, and structural components exposed to harsh environments, offering protection against rust, chemical spills, and weathering.Q: How long does the coating last, and what maintenance is required?

A: Under normal conditions, it lasts 10-15 years with minimal maintenance. Regular inspections are advised, but the coating's resilience reduces the need for frequent touch-ups.Q: Are there customization options for color or thickness?

A: Absolutely, we offer a range of colors and thicknesses (e.g., 25-200 microns) tailored to your project requirements. Contact us for details on custom formulations.Q: What certifications support the quality of this product?

A: Our coatings are produced under certifications including ISO9001, ISO14000, and OHSAS18001, ensuring adherence to international quality and safety standards.Q: How do I apply the coating, and is training available?

A: Application can be done via standard methods like spraying; we provide detailed guidelines and optional on-site training to ensure optimal results for your team.

Send Inquiry to This Supplier

You May Also Like

-

Electrostatic Spray ETFE Fluorocarbon Powder Coating Supply, Heavy Anticorrosion and Acid-Alkali ResistanceUS$ 10 - 50MOQ: 100 Kilograms

-

Fluorocarbon ETFE Powder Coating With High-Performance Acid and Solvent ResistantUS$ 10 - 50MOQ: 100 Kilograms

-

ETFE Fluorocarbon Powder Coating for Electroplating Hangers Jigs Racks, Anti High Temperature 200C ,dip Coating and SprayUS$ 10 - 50MOQ: 100 Kilograms

-

High Temperature Resistant ETFE Fluorocarbon Powder Coating – Heavy Anticorrosion & Acid-Alkali Resistant for Industrial EquipmentUS$ 2 - 5MOQ: 1000 Kilograms

-

High Hardness & Electrical Insulation ETFE Fluorocarbon Powder Coating – Ideal for Electronics & Mechanical PartsUS$ 2 - 5MOQ: 1000 Kilograms

-

ROHS Certified ETFE Fluorocarbon Powder Coating – Long-Lasting Wear Resistance & Environmental ProtectionUS$ 2 - 5MOQ: 1000 Kilograms

-

Electrostatic Spray ETFE Fluorocarbon Powder Coating – Multifunctional Protection for Steel SubstratesUS$ 2 - 5MOQ: 1000 Kilograms

-

ETFE Fluorocarbon Powder Coating for Chemical Resistance up to 150°CUS$ 2 - 5MOQ: 1000 Kilograms

-

ETFE Fluorocarbon Powder for Electrical Insulation With 10^16 Ohm·cm ResistivityUS$ 2 - 5MOQ: 1000 Kilograms

-

Mold Release Agent for Bakery Industry CompliantUS$ 1 - 4MOQ: 200 Kilograms