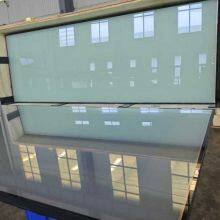

12mm Spacer Insulating Glass for Extreme Climate Zones

QinHuangDao LianYiDing Glass Co., Ltd., a trusted manufacturer established in 2003 with over two decades of expertise in advanced glazing solutions, proudly presents our specialized 12mm Spacer for Insulating Glass. Engineered specifically for the demanding conditions of extreme climate zones, this spacer is the critical component that elevates the thermal performance, longevity, and reliability of your insulating glass units (IGUs). Operating from our 5,000-10,000 sqm facility in Hebei, China, and backed by a dedicated workforce of 201-300 professionals, we consistently deliver components that meet rigorous international standards, serving discerning markets across North America, South America, Europe, and Asia. Our commitment to quality management, evidenced by ISO9001 and ISO14000 certifications, ensures this spacer provides the robust thermal break necessary to combat severe temperature fluctuations, minimize condensation, and significantly enhance building energy efficiency.

This 12mm spacer is not just a component; it's a precision-engineered solution designed to address the unique challenges faced by windows and doors in regions experiencing intense cold, heat, or significant daily temperature swings. Its core function is to create a stable, high-performance cavity within double or triple glazed IGUs.

Key Features & Technical Advantages:

- Superior Thermal Performance: The 12mm cavity width, optimized for extreme climates, significantly increases the insulating air space, dramatically reducing heat transfer (U-value) compared to narrower spacers. This directly translates to lower energy costs for heating and cooling.

- Advanced Condensation Resistance: Featuring a warm edge design principle, the spacer minimizes heat conduction at the critical edge of the glass unit. This raises the temperature of the inner glass edge, effectively pushing the dew point outward and drastically reducing the risk of condensation and frost formation, even in sub-zero temperatures or high humidity environments.

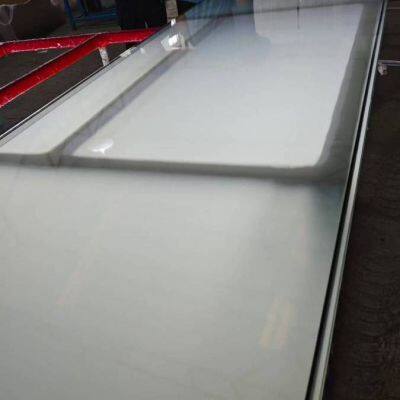

- Robust Construction & Durability: Constructed with a high-strength aluminum alloy core integrated with a continuous, corrosion-resistant stainless steel moisture vapor barrier. This ensures:

- Exceptional dimensional stability under pressure and temperature variations.

- Superior long-term resistance to gas leakage (Argon, Krypton) essential for maintaining optimal insulating performance over the lifespan of the IGU.

- Enhanced resistance to desiccant saturation and failure.

- Optimized for Structural Integrity: The 12mm width provides excellent rigidity, contributing to the overall structural stability of the IGU, particularly important for larger pane sizes common in modern architecture.

- Compatibility & Versatility: Designed for seamless integration into standard IGU manufacturing processes using dual or triple seal systems (e.g., butyl primary seal + polysulfide or silicone secondary seal). Suitable for use with various glass types (clear, low-e, tempered, laminated) and gas fills.

- Enhanced Sound Insulation: The wider air gap contributes to improved acoustic performance by providing a larger buffer zone for sound wave attenuation.

Core Technical Specifications:

| Parameter | Value | Benefit |

|---|---|---|

| Spacer Width | 12 mm | Optimal cavity size for extreme climate thermal & acoustic performance |

| Core Material | Aluminum Alloy | High strength, dimensional stability |

| Vapor Barrier | Stainless Steel | Superior corrosion resistance, long-term moisture barrier integrity |

| Thermal Conductivity | Low (Warm Edge Principle) | Reduces edge heat loss, minimizes condensation risk |

| Primary Application | Extreme Climate Zone IGUs | Arctic, desert, high-altitude, high-humidity regions |

| Compatible Sealants | Butyl, Polysulfide, Silicone | Flexible integration into standard manufacturing |

Benefits for Your Business & End-Users:

- Significant Energy Savings: Drastically reduce heating and cooling loads for buildings, leading to lower operational costs and enhanced sustainability credentials.

- Improved Occupant Comfort: Eliminate cold drafts near windows and prevent condensation, creating a more comfortable and healthier indoor environment.

- Extended IGU Lifespan: Superior resistance to moisture ingress and desiccant failure ensures the insulating performance and structural integrity of the IGU lasts longer, reducing replacement costs.

- Enhanced Building Value: Contributes to achieving higher energy efficiency ratings (e.g., LEED, BREEAM) and meeting stringent building codes for extreme climates.

- Reduced Warranty Claims: Minimize issues related to condensation and premature IGU failure, protecting your reputation and bottom line.

When sourcing critical components for high-performance insulating glass destined for the world's harshest environments, trust matters. QinHuangDao LianYiDing Glass Co., Ltd. brings the assurance of nearly 20 years of manufacturing excellence. Our commitment to quality is embedded in our ISO9001 and ISO14000 certified processes, ensuring every 12mm spacer meets exacting standards for performance and durability. Supported by a skilled workforce of 201-300 and a significant production footprint, we possess the capacity and expertise to be your reliable partner. Our products are trusted by clients across North America, South America, Eastern and Western Europe, Northern and Southern Europe, and Asia, shipped efficiently from ports like Tianjin, Dalian, and Qinhuangdao. Choose our 12mm Extreme Climate Spacer to deliver unparalleled thermal efficiency, condensation resistance, and long-term reliability in your insulating glass units. Experience the difference robust engineering and proven quality can make. Contact LianYiDing Glass today to discuss your requirements, request samples, or place an order. Let us help you build better, more energy-efficient windows for the most demanding climates.

Frequently Asked Questions (FAQ):

-

Q: Why is a 12mm spacer specifically recommended for extreme climates?

A: A 12mm cavity provides a significantly larger insulating air space compared to standard 6mm or 9mm options. This wider gap dramatically reduces conductive and convective heat transfer (lower U-value) and improves sound insulation. It's crucial for maintaining interior comfort and minimizing energy loss in areas with severe temperature extremes (very hot or very cold). -

Q: How does the 'warm edge' design of this spacer prevent condensation?

A: The spacer's construction (aluminum core + stainless steel barrier) has lower thermal conductivity than traditional all-aluminum spacers. This reduces the amount of heat escaping through the edge of the glass unit. By keeping the inner glass edge warmer, the surface temperature stays above the dew point of the indoor air more effectively, preventing moisture from condensing on the glass surface inside the room. -

Q: Is this spacer compatible with gas fills like Argon or Krypton?

A: Yes, absolutely. The robust stainless steel vapor barrier and compatibility with high-quality secondary sealants (like polysulfide or silicone) are specifically designed to ensure excellent long-term retention of inert gas fills (Argon, Krypton), which are essential for maximizing the thermal performance of IGUs in extreme climates. -

Q: What certifications does LianYiDing hold for manufacturing this spacer?

A: Our manufacturing processes are certified to ISO9001 (Quality Management) and ISO14000 (Environmental Management) standards. This ensures consistent quality, process control, and environmental responsibility in the production of our spacers. We adhere to relevant industry standards for insulating glass components. -

Q: Can you provide spacers in custom lengths or shapes?

A: Yes, as a manufacturer, we offer significant flexibility. While standard straight lengths are readily available, we can produce custom lengths and shapes (e.g., bent for curved IGUs) to meet specific project requirements. Please inquire about your custom needs. -

Q: What are the main advantages of your spacer over standard aluminum box spacers?

A: Our spacer offers several key advantages:- Superior Thermal Break: Lower conductivity reduces edge heat loss significantly.

- Enhanced Condensation Resistance: Warmer inner edge minimizes condensation risk.

- Improved Durability & Gas Retention: Stainless steel barrier offers better long-term resistance to corrosion and moisture/gas permeation compared to standard aluminum.

- Optimal for Extreme Climates: The 12mm width is specifically chosen for maximum performance in harsh conditions.

-

Q: What is the typical lead time for orders?

A: Lead times vary based on order volume and specific requirements (standard vs. custom). We prioritize efficient production and shipping from our ports (Tianjin, Dalian, Qinhuangdao). Please contact us with your project details for an accurate lead time estimate. -

Q: Do you offer technical support for IGU manufacturers using your spacer?

A: Yes, we provide technical data sheets and can offer guidance on best practices for integrating our 12mm spacer into your IGU manufacturing process to achieve optimal performance, especially for extreme climate applications.

Send Inquiry to This Supplier

You May Also Like

-

Low-E Insulating Glass With Reduced Transparency for Energy EfficiencyNegotiableMOQ: 100 Square Meters

-

Durable High-Performance Three-Layer Tempered Insulated GlassNegotiableMOQ: 100 Square Meters

-

Customized Cut Size Air Argon Aluminum Spacer Vacuum Insulated Glass for Large WindowsNegotiableMOQ: 100 Square Meters

-

Colored Tinted Reflective Laminated Low-E Glass for Architectural UseNegotiableMOQ: 100 Square Meters

-

Energy-Saving Low-E Tempered Double IGU Glass for Curtain Walls and DoorsNegotiableMOQ: 100 Square Meters

-

3mm-12mm Flat/Curved/Bent Laminated Safety Glass for Windows and DoorsNegotiableMOQ: 100 Square Meters

-

Tempered Glass for Window, Building, and Curtain Wall ConstructionNegotiableMOQ: 100 Square Meters

-

Float Reflective Frosted Acid Etched Laminated Safety Glass for Building DecorationNegotiableMOQ: 100 Square Meters

-

Triple Silver Low-E Insulating Glass Unit (6+12A+6mm) for Energy EfficiencyNegotiableMOQ: 100 Square Meters

-

Float Reflective Frosted Acid Etched ESG/VSG Laminated Safety Glass for Decorative ConstructionNegotiableMOQ: 50 Square Meters