Tempered Laminated Glass Railings for Earthquake-Prone Regions

As a specialized manufacturer with over 20 years of expertise in architectural glass solutions, QinHuangDao LianYiDing Glass Co.,Ltd proudly presents our engineered Tempered Laminated Glass Railings, designed specifically for structural safety in earthquake-vulnerable zones. Founded in 2003 and operating from a 5,000-10,000 sqm facility in China, we combine advanced manufacturing with rigorous ISO-certified processes (ISO9001, ISO14000, ISO19011:2000) to deliver products trusted across global markets including North America, Europe, and Asia. Our railings integrate critical seismic resilience without compromising aesthetics, offering architects and builders a reliable solution for modern, code-compliant construction.

Core Engineering & Benefits:

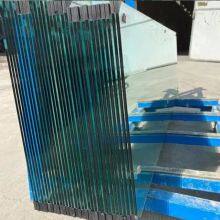

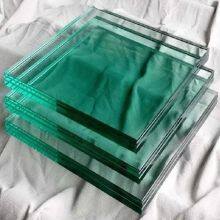

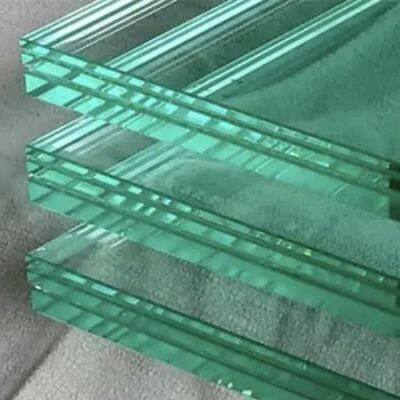

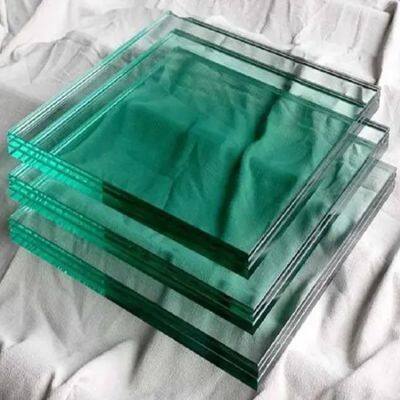

- Dual-Safety Construction: Features a PVB interlayer bonding two sheets of tempered glass. Under seismic stress, glass fragments adhere to the interlayer, preventing hazardous collapse and maintaining barrier integrity.

- Enhanced Structural Flexibility: The laminated design allows slight flexing during tremors, absorbing energy and reducing point-load stress on mounting systems compared to monolithic glass.

- Superior Impact Resistance: Exceeds 5x the impact strength of standard tempered glass, crucial for high-traffic/public areas even beyond seismic events.

-

Advanced Mounting Systems: Compatible with seismic-rated hardware (clamps or channels) allowing controlled movement at connections. Options include:

- Top & bottom continuous channel systems

- Patch-fittings with flexible neoprene pads

- Structural silicone glazing (SSG)

- UV & Weather Stability: PVB interlayer blocks 99% UV radiation, preventing fading and ensuring long-term clarity in harsh climates.

Technical Specifications:

| Parameter | Standard Specification | Customization Options |

|---|---|---|

| Glass Composition | 2x Tempered Glass (6-12mm each) + 1.52mm PVB | Thickness up to 24mm+24mm, SGP/EVA interlayers |

| Height/Width | Max Panel: 2400mm x 4200mm | Engineered solutions for larger spans |

| Seismic Compliance | Designed per IBC/ASCE 7 drift requirements | Specific regional code adaptation (e.g., NZS 1170.5) |

| Load Resistance | Wind Load: Class 3 (AS/NZS 1170.2) Handrail Load: >1.5 kN/m (EN 1991) |

Third-party testing reports available |

Why Choose Our Seismic Railings?

- Risk Mitigation: Reduces liability and protects occupants by maintaining egress paths post-earthquake.

- Low Maintenance: Resistant to corrosion (glass/stainless steel) and unaffected by moisture.

- Design Versatility: Achieve sleek, modern aesthetics with frameless designs or complement traditional architecture with framed options.

- Acoustic Insulation: PVB layer reduces sound transmission by up to 5dB, ideal for urban settings.

Trust & Global Capability:

Backed by a workforce of 201-300 skilled professionals and an annual export value serving diverse markets from North America to South Asia, LianYiDing Glass guarantees consistent quality. We ship majorly via Tianjin, Dalian, and Qinhuangdao ports, ensuring logistical efficiency. Our commitment to ISO 9001 quality management and ISO 14000 environmental standards reflects in every project. Partner with us for railings that don’t just meet codes – they enhance safety resilience and architectural value.

Frequently Asked Questions (FAQ):

-

Q: How does laminated glass improve seismic performance compared to tempered-only glass?

A: During an earthquake, tempered glass can shatter entirely, creating dangerous openings. Laminated glass retains shattered fragments via the PVB interlayer, maintaining the railing’s barrier function and allowing safe evacuation. -

Q: Are your railings suitable for coastal/high-salinity environments?

A: Yes. We recommend 316-grade stainless steel hardware and can apply protective coatings to aluminum frames, making them highly resistant to salt corrosion. -

Q: Can you provide project-specific seismic calculations?

A: Absolutely. Our engineering team can perform deflection analysis and hardware load calculations based on your local building codes and structural drawings upon request. -

Q: What is the lead time for custom-sized seismic railings?

A: Standard orders ship within 25-30 days. Complex customizations (e.g., curved glass, special interlayers) may require 35-45 days. Expedited options are available. -

Q: Do you offer on-site installation supervision?

A: While we provide detailed installation manuals and video support, supervised installation by our technicians can be arranged for large projects (additional cost applies). -

Q: How is impact resistance tested?

A: We conduct pendulum impact tests per EN 12600 Class C (1200mm drop height) or ANSI Z97.1, ensuring the glass withstands human impact without through-break.

Send Inquiry to This Supplier

You May Also Like

-

Customizable Glass Railings for Hotel Atriums and LobbiesNegotiableMOQ: 1 Piece

-

Glass Railings With Integrated LED Lighting for Night SafetyNegotiableMOQ: 1 Piece

-

Low-Iron Glass Railings With Powder-Coated Aluminum FramesNegotiableMOQ: 1 Piece

-

Railings GlassUS$ 1 - 10MOQ: 10 Square Meters

-

Glass RailingsUS$ 1 - 10MOQ: 1 Piece

-

Tempered Glass Railing Panels With Stainless Steel Standoffs for Stair and BalconyUS$ 1 - 10MOQ: 1 Piece

-

Tempered Laminated Glass Railings With Anti-Slip Surface TreatmentUS$ 1 - 10MOQ: 1 Piece

-

Architectural Glass Railings for Office Building AtriumsUS$ 1 - 10MOQ: 1 Piece

-

Frosted Glass Railings With Aluminum Alloy Handrail for HotelsUS$ 1 - 10MOQ: 1 Piece

-

Custom CNC Cut Glass Panels for Modern Railing SystemsUS$ 1 - 10MOQ: 1 Piece