Heavy Duty Gas Cylinder Enclosure- GCE363 With Impact Resistance & Automatic Venting for Aerospace Maintenance Hangar

The Heavy Duty Gas Cylinder Enclosure-GCE363 is engineered to withstand the rugged, fast-paced environment of an active hangar while providing the intelligent protection required to safeguard multi-million dollar aircraft assets.

The Aerospace Challenge: High-Stakes Industrial Environments

Maintenance, Repair, and Overhaul (MRO) facilities are dynamic spaces where heavy machinery, tugs, and tool carts are constantly in motion. Storing high-pressure gas cylinders in these areas introduces specific risks:

Mechanical Impact: The risk of vehicle or equipment collision with gas storage is significantly higher than in a lab.

Large-Scale Ventilation Needs: Hangars are vast, but localized gas leaks in a maintenance bay can still create hazardous pockets of flammable or asphyxiating gas.

Regulatory Compliance: Aerospace facilities must adhere to strict FAA, EASA, and local fire marshal safety codes regarding the storage of hazardous materials.

Key Features: Engineered for the Hangar Floor

1. Superior Impact Resistance Architecture

The GCE363 is not just a cabinet; it is a fortified enclosure.

Extra-Thick Steel Plate: Utilizing a reinforced cold-rolled steel frame, the GCE363 is designed to absorb and deflect physical impacts, protecting the sensitive valves and regulators inside.

Structural Reinforcement: The unit features internal bracing and a heavy-duty base plate that ensures the enclosure remains upright and intact, even in the event of an accidental bump from a ground service vehicle.

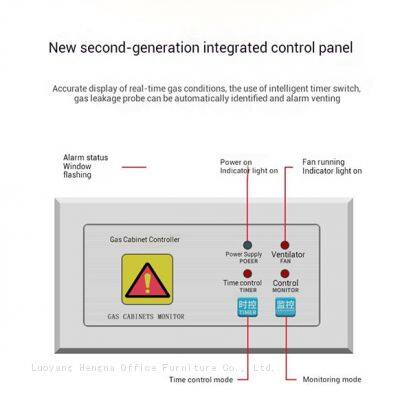

2. Automatic Venting & Smart Airflow Logic

Safety in an aerospace hangar requires proactive air management.

Sensor-Activated Venting: The GCE363 features an integrated gas monitoring system. Upon detection of a leak, the Automatic Venting system activates high-capacity centrifugal fans.

Rapid Dilution: The system is designed to perform a complete air exchange within the cabinet in seconds, venting gases upward and away from the work zone through industrial-grade ducting flanges.

3. High-Security Three-Point Locking System

In a facility where "Foreign Object Damage" (FOD) and unauthorized access are critical concerns, security is paramount.

Tamper-Proof Design: The enclosure is fitted with a heavy-duty three-point locking mechanism that prevents unauthorized personnel from accessing high-pressure valves.

Recessed Handles: To avoid snagging on moving equipment or personnel uniforms, the handles are ergonomically recessed into the door frame.

Technical Specification Table

| Feature | Aerospace MRO Specification |

| Model Number | GCE363 (Aerospace Heavy Duty Series) |

| Primary Material | 1.2mm - 1.5mm Reinforced Cold Rolled Steel |

| Ventilation Type | Automated Linkage High-Volume Venting |

| Impact Protection | Reinforced Frame with Structural Bracing |

| Locking System | Industrial 3-Point Steel Linkage Lock |

| Coating | Anti-corrosion, High-Visibility Safety Finish |

| Capacity | 2 to 4 Large Cylinders (Customizable) |

| Compliance | OSHA 1910.101, NFPA 1, CE |

Optimizing Hangar Operational Safety

The GCE363 is designed to be as "mission-ready" as the aircraft it supports.

Loading Efficiency: The enclosure includes a heavy-duty, low-profile ramp that handles the weight of the largest aviation-grade gas bottles, ensuring quick and safe cylinder swaps during tight maintenance windows.

Visual Status Window: Technicians can verify pressure levels through the explosion-proof glass without unlocking the unit, allowing for faster pre-flight or pre-maintenance inspections.

Earthquake & Vibration Anchoring: Pre-drilled heavy-duty floor mounting points allow the GCE363 to be permanently secured, preventing tipping during seismic events or nearby heavy engine testing.

Reliability for Global Aviation Standards

Whether your MRO facility is in the United States, Europe, or Asia, the GCE363 is built to exceed standard safety requirements. Our manufacturing process includes rigorous stress testing of the auto-venting system to ensure it performs flawlessly under the variable temperatures and pressures found in hangar environments.

Frequently Asked Questions (FAQ)

Q1: Can the GCE363 be installed outdoors near the flight line?

A: Yes, we offer an "All-Weather" variant of the GCE363 that features an additional sloped roof and weather-sealed gaskets. However, the standard model is designed for indoor hangar use.

Q2: How does the "Automatic Venting" connect to our hangar's HVAC?

A: The GCE363 comes with a standard Φ100mm or Φ150mm top-mounted exhaust flange. Your facility team can easily connect this to the building's central exhaust or a dedicated vent line using standard industrial hosing.

Q3: Is the impact resistance rated for specific vehicle speeds?

A: While the GCE363 is built to the highest industrial "Heavy Duty" standards to prevent cylinder damage from tool carts and light tug bumps, we always recommend installing safety bollards around the cabinet in high-traffic vehicle zones for maximum protection.

The Definitive Choice for Aviation MRO

The Heavy Duty Gas Cylinder Enclosure-GCE363 is the professional’s choice for Aerospace Maintenance Hangars. By integrating Impact Resistance with Automatic Venting, it provides a rugged, smart, and compliant solution that ensures your hangar remains a safe environment for both your personnel and your aircraft.

The contact information of the sales manager is shown in the picture below. You can make inquiries directly without waiting.

Send Inquiry to This Supplier

You May Also Like

-

Heavy-Duty Steel Gas Bottle Cabinet With Safety Locks and Leak Detection Sensor for Lab / R&D CenterUS$ 90 - 500MOQ: 5 Combos

-

Customized Ventilated Gas Cylinder Storage Cabinet With Automitic Warning for Industrial Plants | Explosion-Proof DesignUS$ 90 - 500MOQ: 5 Combos

-

Durable Medical Oxygen Cylinder Cabinet With Alarm and Anti-Corrosion Steel Structure for Medical Gas Storage RoomUS$ 90 - 500MOQ: 5 Combos

-

High-Security Compressed Gas Storage Cabinet With Removable Mounting Bracket for Automated Factory Air Supply Station Serving CanadaUS$ 90 - 500MOQ: 5 Combos

-

OSHA/NFPA Compliant Gas Cylinder Cabinet With Warning System for Hazardous Gas StorageUS$ 90 - 500MOQ: 5 Combos

-

GC-HD Smart Steel Gas Cylinder Storage Cabinet | With Dual Alarm System, Heavy Duty Lab Equipment | for Dublin & Cork, IrelandUS$ 180 - 400MOQ: 2 Pieces

-

Explosion-Proof Compressed Gas Storage Cabinet | 2-Bottle Capacity With SensorUS$ 180 - 400MOQ: 2 Pieces

-

Professional 2-Bottle Gas Cylinder Cabinet | Model HN-1900W With Corrosive Resistant Coating | for Canada UAE IndustryUS$ 180 - 400MOQ: 2 Pieces

-

Heavy Duty Industrial Gas Bottle Storage Cabinet | Yellow Safety Steel EnclosureUS$ 180 - 400MOQ: 2 Pieces

-

Smart Double Gas Bottle Locker | With Gas Sensor & Auto Exhaust Fan Model SG-200 | for Australia Germany MarketUS$ 180 - 400MOQ: 2 Pieces