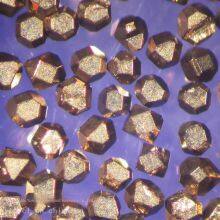

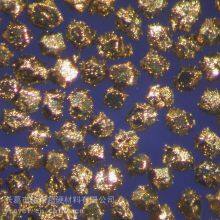

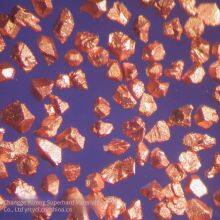

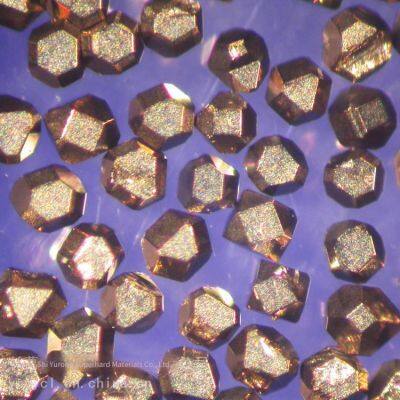

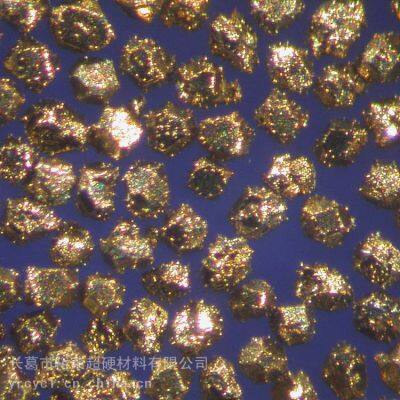

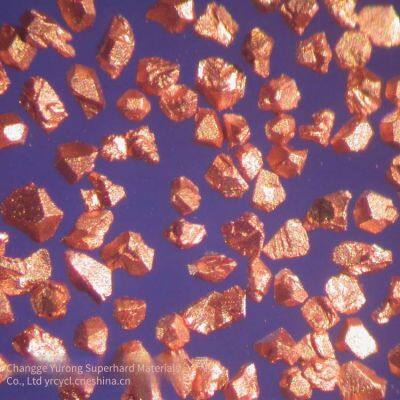

Metal-coated Diamonds, Nickel-plated, Titanium-plated, and Copper-plated Diamonds, 25/30 - 325/400

Superhard material coating (electroplating, composite plating, functional plating) products

1. Electroplated products

Nickel or copper plating on the surface of single-crystal diamond, crushed material or CBN, with a weight gain of 30% or 56%. Nickel plating can improve the mechanical holding force of diamond, slow down thermal shock and increase the service life of products, which is suitable for resin-bonded products. Copper plating can improve the mechanical holding force of diamond and CBN, slow down thermal shock and increase the service life of products. It has a good dry grinding effect and is suitable for resin and bronze-bonded products.

2. Electroless plated products

Electroless nickel plating on the surface of single-crystal diamond, crushed material or CBN with a weight gain of 56% or 30%. The coating has a non-crystalline cellular structure and is hard and brittle. Compared with electroplated nickel products, it has higher processing accuracy and better mechanical holding force, and is especially suitable for resin-bonded products.

3. Composite plated products

Chemical nickel plating plus electroplating nickel on the diamond surface, with a weight gain of 30%. The products have the advantages of less adhesion, concentrated particle size, excellent magnetism and strong corrosion resistance, and are well applied in diamond wire saws, especially in silicon wafer cutting wires.

4. Magnetron sputtering coated products

Using advanced, environmentally friendly and efficient vacuum coating technology, coatings of single metals, alloys, non-metals, etc. are achieved on the diamond surface. The bonding force between the diamond and the coating is strong. The products are widely used in metal-bonded, resin-bonded, ceramic-bonded products and advanced thermal conductive composite materials.

Metal bond Recommended coatings: titanium, tungsten, molybdenum, chromium, zirconium...

Resin bond Recommended coatings: iron-nickel alloy, nickel, copper, copper-tin alloy, aluminum...

Ceramic bond Recommended coatings: tungsten carbide, titanium carbide, titanium carbonitride, aluminum titanium nitride...

Non-metal coatings Recommended coatings: carbon, silicon, etc.

Processing limit: ≥10,000 carats

Coating types: nickel, titanium, tungsten, copper, chromium, etc.

Processable materials: diamond, CBN

Processable specifications: 25/30 - 325/400 (functional plating/electroplating), ≥20μm (electroless plating/composite plating/functional plating)

Processing fee: The thickness of the conventional coating is 30 - 50 nanometers, and the processing fee is 0.30 - 0.60 yuan/carat. For customized thickened coatings of 50 - 100 nanometers, the price doubles.

Purchase instructions:

1. The goods will be delivered about 10 days after the payment arrives in the account.

2. Logistics, express delivery, air transportation, railway transportation, etc. The long-distance transportation cost shall be borne by the seller.

3. The buyer shall comprehensively self-inspect the products according to the standards within seven days after receiving the goods. If there are any objections, they shall be submitted in writing within ten days. Otherwise, the products can be regarded as qualified in quality.

Making high - quality products is the direction of our unremitting efforts; Your trust is the support for us!

Send Inquiry to This Supplier

You May Also Like

-

Cbn Cubic Boron Nitride 60/70 - 400/500US$ 0.09 - 0.09MOQ: 10000 Carats

-

Diamond Micropowder, Diamond Polishing Powder, W0.5 - W60US$ 0.07 - 0.08MOQ: 10000 Kilograms

-

OEM Different Sizes of Shining Diamond Painting With Full Set of Tools for Artcraft and DisplayNegotiableMOQ: 100 Sets

-

2022 New Color Night Light Aromatherapy Diamond Water Drop Ultrasonic Air Humidifier(Wechat:13510231336)NegotiableMOQ: 2000 Pieces

-

Easily Assembled Galvanized Diamond Wire Mesh and Waterproof Pvc Coated Chain Link Fences PriceUS$ 6.60 - 15.40MOQ: 100 Square Meters

-

Bowling Range Diamond With IlluminationUS$ 50 - 2000MOQ: 10 Pieces

-

Microhardness Testing Device Diamond /Diamond Rockwell Indenter Hardness TesterNegotiableMOQ: 1

-

Carbide Diamond Plastic Box PackageUS$ 0.13 - 0.20MOQ: 500 Pieces

-

New Product Diamond Sugar Mishri Making MachineNegotiableMOQ: 1

-

Diamond Drill Crown Core Drilling Bit for Concrete Masonry Wall Diamond Core Drill BitNegotiableMOQ: 50 Pieces